Content Menu

● What Is a HEPA Air Filter?

● How Long Does a HEPA Filter Last in an Air Purifier?

● Signs Your HEPA Air Filter Needs Replacement

● Factors That Affect HEPA Air Filter Lifespan

>> 1. Environmental Particle Load

>> 2. Operating Schedule

>> 3. Humidity and Temperature Conditions

>> 4. Industrial Cleanliness Standards

>> 5. Filter Installation Quality

● Optimizing HEPA Air Filter Performance in Pharmaceutical Environments

● Industrial Applications of HEPA Air Filtration

>> Pharmaceutical Manufacturing

>> Biotechnology and Laboratory Use

>> Medical and Healthcare Facilities

>> Electronics Manufacturing

>> Food and Beverage Processing

● Maintenance Tips for HEPA Air Filters

● How to Dispose of Used HEPA Air Filters Safely

● The Relationship Between Air Purity and Production Quality

● Conclusion

● FAQ

>> 1. How often should a HEPA Air Filter be replaced?

>> 2. Can a HEPA Air Filter be cleaned and reused?

>> 3. What's the difference between HEPA and ULPA filters?

>> 4. Do HEPA Air Filters remove viruses?

>> 5. How can I extend the lifespan of HEPA Air Filters?

Air purification plays an essential role in industrial and pharmaceutical environments where air quality directly affects production safety, cleanliness, and final product quality. One of the most critical components in modern air purifiers is the HEPA Air Filter, known for its ability to trap microscopic particles and maintain controlled air purity levels. However, one commonly asked question remains: *How long does a HEPA filter last in an air purifier?*

In this article, we will explore the working principles of HEPA filters, their lifespan under various conditions, signs that indicate replacement, factors that influence performance, and how industrial users — especially in fields like pharmaceuticals — can optimize filtration efficiency through proper system design and maintenance.

What Is a HEPA Air Filter?

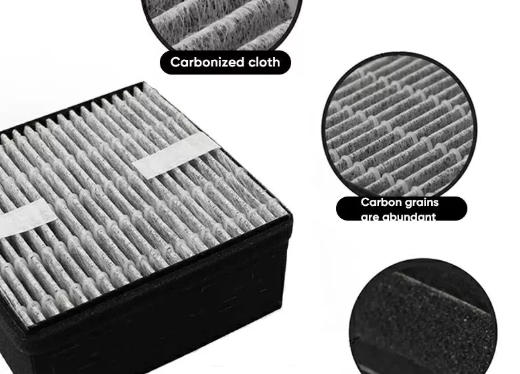

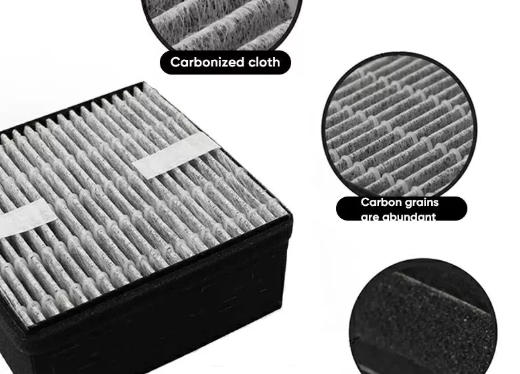

A HEPA Air Filter, or High-Efficiency Particulate Air filter, is a tightly woven mat of fibers that captures airborne contaminants with exceptional precision. By definition, HEPA filters remove at least 99.97% of particles that are 0.3 microns in diameter. This includes dust, bacteria, pollen, smoke particles, and even many types of microorganisms found in controlled environments.

HEPA filters are widely used in industries that demand high levels of air purity, such as:

- Pharmaceutical and biotechnology manufacturing

- Food and beverage processing

- Semiconductor fabrication

- Hospital cleanrooms and laboratories

- Precision electronics manufacturing

In pharmaceutical equipment manufacturing, HEPA Air Filters serve as the backbone of sterilization systems, cleanroom ventilation, and product packaging environments, ensuring product safety and compliance with GMP (Good Manufacturing Practice) standards.

How Long Does a HEPA Filter Last in an Air Purifier?

The lifespan of a HEPA Air Filter generally ranges from 6 months to 3 years, depending on the usage environment and maintenance practices. However, this duration is not fixed because multiple factors determine how quickly the filter becomes saturated with particles.

For household air purifiers, manufacturers often recommend replacing the HEPA filter every 12 to 18 months. In contrast, industrial-grade filters used in cleanrooms or pharmaceutical facilities may require more frequent replacement — sometimes every 6 to 12 months — to maintain strict air quality control.

The exact life expectancy depends on:

1. Air quality of the surrounding environment

In dusty or polluted regions, HEPA filters accumulate particles much faster, shortening their effective lifespan.

2. Operating hours and airflow rate

Continuous 24-hour operation at high flow rates wears out filters faster than intermittent, low-flow usage.

3. Filter design and quality

Premium HEPA Air Filters made with advanced materials or multi-layer configurations can deliver longer service life.

4. Pre-filtration systems

Using pre-filters to capture large dust particles before they reach the HEPA membrane can extend the lifespan substantially.

5. Maintenance and sterilization conditions

In pharmaceutical environments where filters are periodically sterilized, the heat and humidity may slightly reduce the filter's effective life, depending on material composition.

Signs Your HEPA Air Filter Needs Replacement

Recognizing when your HEPA Air Filter requires replacement is crucial for maintaining both performance and energy efficiency. Here are some common indicators:

- Reduced air flow: If the purifier's output feels weaker, the filter might be clogged.

- Decrease in purification efficiency: Persistent odors or higher particulate readings suggest reduced filtration performance.

- Visual discoloration: A gray or darkened surface often means the HEPA filter has trapped maximum contaminant loads.

- Indicator alerts: Many modern air purifiers feature electronic alerts signaling when filter replacement is due.

- Noise increase: When airflow struggles through a blocked filter, motor strain can cause unusual noise levels.

Waiting too long to replace a clogged HEPA Air Filter can lead to not only reduced air quality but also increased energy consumption, as the system must work harder to maintain air volume output.

Factors That Affect HEPA Air Filter Lifespan

1. Environmental Particle Load

The higher the dust, pollen, or smoke level in the air, the faster your HEPA Air Filter will saturate. Factories located near construction zones or heavy traffic areas often experience shorter filter life.

2. Operating Schedule

Air purifiers that operate continuously for 24 hours a day naturally require earlier filter replacement compared to systems used only during shift hours.

3. Humidity and Temperature Conditions

Humidity affects fiber density and can promote microbial growth on neglected filters. In high-humidity climates or cleanrooms using steam sterilization equipment, filters must meet defined thermal and biological resistance standards.

4. Industrial Cleanliness Standards

Pharmaceutical industries follow strict protocols to prevent microbial contamination. Therefore, filters must be replaced promptly based on validation cycles, not just visible signs of dirt.

5. Filter Installation Quality

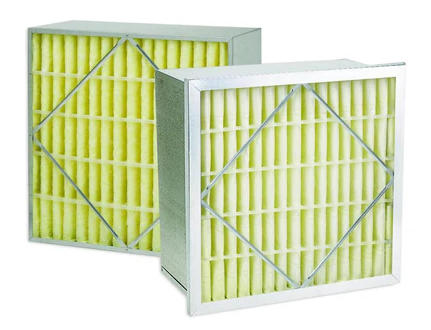

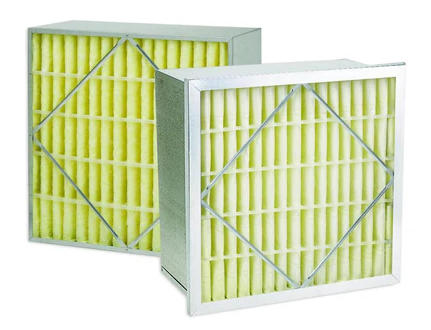

Improper fitting allows unfiltered air to bypass the system, reducing effectiveness and increasing contamination risks. Always ensure filters are installed according to the manufacturer's specifications.

Optimizing HEPA Air Filter Performance in Pharmaceutical Environments

At Everheal, we specialize in designing and integrating advanced purification systems for pharmaceutical production facilities. A key element in these systems is the integration of HEPA Air Filters within pure steam generators, distilled water systems, filling and sealing equipment, and sterilization modules.

To maximize HEPA filter lifespan and maintain stable production quality, it is essential to combine engineering design with smart maintenance strategies:

- Include multilayer filtration: Begin with coarse pre-filters to capture large particles.

- Optimize airflow dynamics: Uniform air distribution increases filter utilization.

- Use pressure differential monitoring: Electronic pressure sensors can detect early clogging.

- Establish preventive maintenance schedules: Replace filters based on operating hours and validation intervals rather than waiting for failure.

- Invest in certified filters: Only use filters rated by EN 1822 or similar international standards for pharmaceutical use.

By combining these strategies with Everheal's customized system design, pharmaceutical manufacturers can create cleaner, safer work environments while reducing overall maintenance cost and downtime.

Industrial Applications of HEPA Air Filtration

Pharmaceutical Manufacturing

Pharmaceutical production relies heavily on contamination-free environments. HEPA Air Filters are used in:

- Cleanrooms for sterile filling and packaging

- Laminar airflow cabinets for sample preparation

- Sterilization chambers connected with steam and purified water systems

- Air return ducts to maintain positive air pressure environments

Biotechnology and Laboratory Use

In research laboratories, HEPA Air Filters protect both products and personnel. They ensure viral, bacterial, and particulate containment during sensitive biological experiments.

Medical and Healthcare Facilities

Hospital air handling systems use HEPA purification to prevent airborne infections, especially in surgical theaters and isolation rooms.

Electronics Manufacturing

Even microscopic dust particles can ruin circuit boards or optical components, making HEPA Air Filters essential in semiconductor and precision optical production lines.

Food and Beverage Processing

Airborne microorganisms and dust can contaminate equipment or products. HEPA Air Filters enhance air hygiene in bottling lines and packaging rooms.

Maintenance Tips for HEPA Air Filters

To preserve optimal performance and extend the filter lifespan, regular maintenance is essential:

1. Inspect filters monthly: Even if not yet due for replacement, check for visible contamination or odor buildup.

2. Use pre-filters: Always install coarse pre-filters in high-dust environments.

3. Keep surrounding areas clean: Vacuum or mop nearby spaces to reduce airborne particle load.

4. Record operational data: Track pressure differentials and air flow rates. Rising differential pressures indicate filter clogging.

5. Avoid manual cleaning: Do not wash or blow compressed air through HEPA Air Filters; it can damage fibers and reduce efficiency.

Implementing these steps ensures consistent cleanroom air integrity and prolongs equipment life.

How to Dispose of Used HEPA Air Filters Safely

Used filters may contain biological contaminants or hazardous dust particles. To ensure environmental and worker safety:

- Seal in polyethylene bags immediately after removal.

- Label as “Used HEPA Filters – Non-reusable.”

- Follow local regulations for hazardous or biological waste disposal.

- Never reuse or incinerate filters unless guided by environmental protection standards.

Proper disposal protects operators, downstream systems, and the surrounding environment.

The Relationship Between Air Purity and Production Quality

In pharmaceutical and medical device industries, air purity directly influences product sterility. A clogged or degraded HEPA Air Filter can compromise the aseptic environment, causing costly production losses or safety noncompliance. By integrating intelligent air purification systems equipped with real-time filter monitoring, companies can ensure that air cleanliness remains within GMP limits.

Reliable filtration not only protects human health but also enhances long-term production stability, supporting continuous manufacturing and regulatory compliance.

Conclusion

A HEPA Air Filter is more than just a replacement component; it is the core of every air purification and cleanroom control system. On average, filters last from 6 months to 3 years, depending on usage patterns, environment, and quality of pre-filtration. Industrial users, particularly in the pharmaceutical sector, can significantly extend filter life through optimized layout planning, air pre-treatment, and scheduled maintenance.

At Everheal, our mission is to deliver comprehensive air and water purification systems that exceed industry standards. By selecting high-efficiency HEPA Air Filters and integrating them into carefully engineered factory solutions, we help global clients achieve superior purity, productivity, and reliability.

FAQ

1. How often should a HEPA Air Filter be replaced?

Typically every 6 to 18 months, depending on environmental conditions and usage frequency. Industrial users should follow operational validation cycles or maintenance schedules set by quality control departments.

2. Can a HEPA Air Filter be cleaned and reused?

No. Washing or blowing compressed air damages the fiber structure, reducing its effectiveness. HEPA filters are designed for one-time use only.

3. What's the difference between HEPA and ULPA filters?

While HEPA filters remove 99.97% of 0.3-micron particles, ULPA filters can remove 99.999% of particles as small as 0.12 microns. ULPA is used in ultra-clean environments such as semiconductor or microchip fabrication.

4. Do HEPA Air Filters remove viruses?

Yes, to a large extent. HEPA filters can capture airborne droplets and viral particles attached to aerosols, effectively reducing virus transmission in controlled environments.

5. How can I extend the lifespan of HEPA Air Filters?

Use pre-filters, monitor differential pressure, maintain clean surroundings, and replace filters following a preventive maintenance schedule rather than waiting for performance decline.