Content Menu

● Understanding the Washable Air Filter

>> Key Features

>> Typical Applications

● Importance of Proper Filter Maintenance

>> Benefits of Routine Cleaning

● How To Take and Wash a Washable Air Filter

>> Step 1: Turn Off the System

>> Step 2: Remove the Filter

>> Step 3: Inspect the Filter

>> Step 4: Pre-clean with Compressed Air

>> Step 5: Wash with Water and Neutral Detergent

>> Step 6: Rinse Completely

>> Step 7: Dry Properly

>> Step 8: Reinstall and Record Maintenance

● Common Mistakes to Avoid

● Recommended Cleaning Frequency

● Advantages of a Washable Air Filter in Industrial Systems

● Signs That Your Washable Air Filter Needs Replacement

● Conclusion

● FAQs About Washable Air Filters

>> 1. What is the lifespan of a washable air filter?

>> 2. Can I use high-pressure water to clean the filter?

>> 3. How can I tell when the filter needs cleaning?

>> 4. Are washable air filters suitable for pharmaceutical environments?

>> 5. What happens if I reinstall the filter while it's still wet?

A washable air filter is a practical, cost-effective, and environmentally friendly solution for air filtration in pharmaceutical, industrial, and commercial environments. Unlike disposable filters that must be replaced frequently, washable filters can be cleaned and reused multiple times without losing efficiency. Proper maintenance ensures that these filters continue to perform at optimal levels, providing clean, contaminant-free air for sensitive applications like cleanrooms, production workshops, and medical facilities.

Whether you use washable air filters in pharmaceutical water systems, steam generation systems, or HVAC units, learning how to properly take and maintain them is essential. This guide explores everything you need to know about handling, cleaning, and preserving washable air filters, especially in sustainable, high-performance manufacturing facilities similar to those supported by Everheal.

Understanding the Washable Air Filter

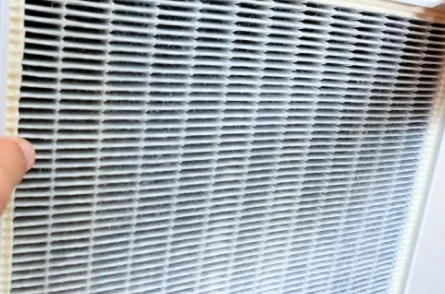

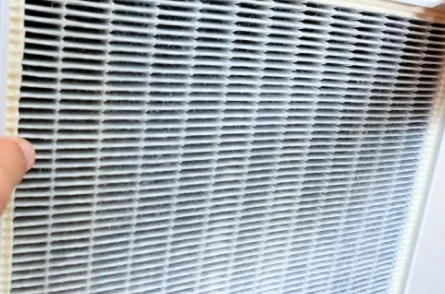

A washable air filter is designed to remove particles, dust, and contaminants from the air while allowing for easy cleaning and reuse. These filters are typically made of materials like aluminum mesh, stainless steel, or electrostatic synthetic fibers. The structure allows air to flow freely while trapping particulates on the surface.

Key Features

- Reusability: Can be washed and reused multiple times, extending service life.

- Durability: Constructed from corrosion-resistant materials suitable for industrial use.

- Eco-friendliness: Reduces waste generated from disposable filters.

- Cost efficiency: Lowers replacement costs over time.

- Stable performance: Maintains filtration efficiency after cleaning if properly cared for.

Typical Applications

- HVAC systems in pharmaceutical cleanrooms.

- Sterile processing and filling machine ventilation.

- Water purification system air supply lines.

- Industrial steam generation systems.

- General ventilation for controlled environments.

Washable air filters play a critical role in ensuring environmental control and process reliability, especially where air purity directly affects product safety and quality.

Importance of Proper Filter Maintenance

Regular maintenance of a washable air filter not only prolongs its lifespan but also enhances system performance. Clean filters ensure smooth airflow and prevent mechanical stress on fans, blowers, and compressors.

Benefits of Routine Cleaning

1. Prevents clogging: Removes dust buildup that can cause reduced airflow.

2. Enhances efficiency: Improves operational performance and lowers energy consumption.

3. Ensures air purity: Reduces risk of contamination in sensitive production areas.

4. Extends lifespan: Maintains the integrity of the filter media and structure.

5. Reduces downtime: Minimizes system failure due to poor air quality.

For industries like pharmaceuticals or food production—where air cleanliness is regulated—filter maintenance is not optional but mandatory.

How To Take and Wash a Washable Air Filter

Handling and cleaning your washable air filter correctly ensures that it continues providing clean air while preserving efficiency. Below is a step-by-step guide for safely removing, washing, drying, and reinstalling the filter.

Step 1: Turn Off the System

Before removing the filter, shut down the HVAC or air circulation system. This prevents dust from being drawn into ducts and protects personnel from accidental suction.

Step 2: Remove the Filter

Open the ventilation or filter housing using the appropriate tools. Carefully slide out the washable air filter without bending or damaging its frame. For pharmaceutical or cleanroom uses, wear gloves to maintain cleanliness during handling.

Step 3: Inspect the Filter

Visually inspect the washable air filter for any visible damage, deformation, or wear. Look for holes, loose mesh, or corrosion. Replace the filter if it shows signs of deterioration that could affect performance.

Step 4: Pre-clean with Compressed Air

If the filter surface is heavily coated with dust, use compressed air or a vacuum cleaner to remove loose particles before washing. Always blow air in the reverse direction of airflow, preventing deeper embedding of particles.

Step 5: Wash with Water and Neutral Detergent

Rinse the washable air filter thoroughly under running water. For oily or greasy deposits, use a mild neutral detergent mixed with warm water.

Avoid using strong chemicals or high-pressure sprays directly against the mesh, as this could damage the filter.

- Temperature: 30–40°C is ideal.

- Detergent ratio: About 1:50 dilution.

Gently agitate the filter to loosen contaminants. Do not scrub excessively to avoid damaging the filtering material.

Step 6: Rinse Completely

After washing, rinse the filter thoroughly with clean water to remove all detergent residue. Residual soap can restrict airflow and attract more dust.

Step 7: Dry Properly

Shake off excess water gently and let the washable air filter air dry in a clean, shaded area. Avoid direct sunlight or heating equipment that might deform the frame or melt the filter medium.

Ensure the filter is completely dry before reinstalling—it should contain no moisture that might lead to mold growth or corrosion.

Step 8: Reinstall and Record Maintenance

Once dry, reinstall the washable air filter carefully in its correct orientation. Ensure all edges are properly sealed to prevent unfiltered air bypass.

Record the cleaning date and condition in the system maintenance log for future tracking.

Common Mistakes to Avoid

Even though washable air filters are simple to maintain, some common errors can reduce their lifespan or efficiency:

- Using high-pressure washers that damage filter fibers.

- Applying corrosive cleaners or strong solvents.

- Skipping drying before reinstalling the filter.

- Ignoring scheduled maintenance intervals.

- Cleaning too frequently or not frequently enough, depending on air quality conditions.

By avoiding these mistakes, companies ensure optimal filter performance and compliance with industry standards.

Recommended Cleaning Frequency

The cleaning frequency for a washable air filter depends on several factors:

Environment Type Cleaning Frequency Notes

Pharmaceutical cleanrooms Every 1–2 weeks Maintain ISO cleanliness levels

Industrial manufacturing areas Every 3–4 weeks Adjust frequency based on dust load

Commercial HVAC systems Every 1–2 months Visual inspection required

Outdoor air handling units Every 2–4 weeks Consider weather and pollution levels

Using a pressure differential gauge can help determine when cleaning is needed. When the pressure drop across the filter exceeds the recommended limit, it's time for washing.

Advantages of a Washable Air Filter in Industrial Systems

Washable air filters provide clear advantages for high-demand operations such as pharmaceutical manufacturing:

- Sustainability: No frequent disposal of used filters.

- Lower total cost of ownership: Reduced replacement and logistics expenses.

- Operational stability: Consistent airflow and filtration performance.

- Regulatory compliance: Meets GMP standards for controlled environments.

- Compatibility: Fits easily into systems like pure water generators, sterilizers, and filling equipment.

Everheal's clients benefit from customized air filtration and plant layout solutions specifically optimized for washable filter integration.

Signs That Your Washable Air Filter Needs Replacement

Even a washable air filter has a finite lifespan. Replace it when:

- The frame becomes corroded or warped.

- Mesh or fiber layers show persistent clogging or damage.

- Airflow does not improve after cleaning.

- Pressure drop remains high even after maintenance.

Typically, washable filters last between 3–5 years under normal industrial conditions.

Conclusion

Maintaining a washable air filter properly ensures long-lasting performance, clean airflow, and compliance with industrial standards. By following correct cleaning and drying procedures, organizations can significantly enhance air quality while saving costs. Regular inspections and responsible maintenance not only extend equipment life but also contribute to sustainable manufacturing operations.

For industries such as pharmaceuticals, biotechnology, or precision electronics—where even the smallest airborne particle matters—the reliability of washable air filters supports both product integrity and environmental responsibility. With structured maintenance procedures and professional planning, facilities can enjoy efficient, consistent, and eco-friendly air purification.

FAQs About Washable Air Filters

1. What is the lifespan of a washable air filter?

A washable air filter usually lasts between 3 to 5 years, depending on the air quality and cleaning frequency. Regular inspection ensures early detection of wear and tear.

2. Can I use high-pressure water to clean the filter?

It's not recommended. High-pressure jets may damage the mesh or cause deformation. Gentle rinsing or low-pressure water flow is safer and preserves filter integrity.

3. How can I tell when the filter needs cleaning?

You can monitor the pressure differential across the filter. When it increases beyond the manufacturer's recommended range, or when visible dust accumulates, it's time to clean.

4. Are washable air filters suitable for pharmaceutical environments?

Yes, washable air filters are commonly used in pharmaceutical HVAC and water purification systems, provided they are regularly maintained and validated for sterile operations.

5. What happens if I reinstall the filter while it's still wet?

Reinstalling a wet filter can lead to bacterial growth and system corrosion. Always ensure complete drying before reinstalling it into the system.