|

Specifications and Technical Parameters

1. Output Water Flow: 250L/h-100000L/h

2. Working Temperature: 5 - 35 ºC

3. Working Pressure: 0.5 -1.55 MPa

Model NO.

| Customized | Warranty

| 1 Year |

| After-Sales Service | Field Installation, Commissioning and Training | Technique | Membrane Separation Technology |

| Material | Steinless Steel | Function | Water Purification |

| Trademark | EVERHEAL | Processing Service | Welding |

| Surface Finish | Tshs | Application | Pharmaceutical & Medical |

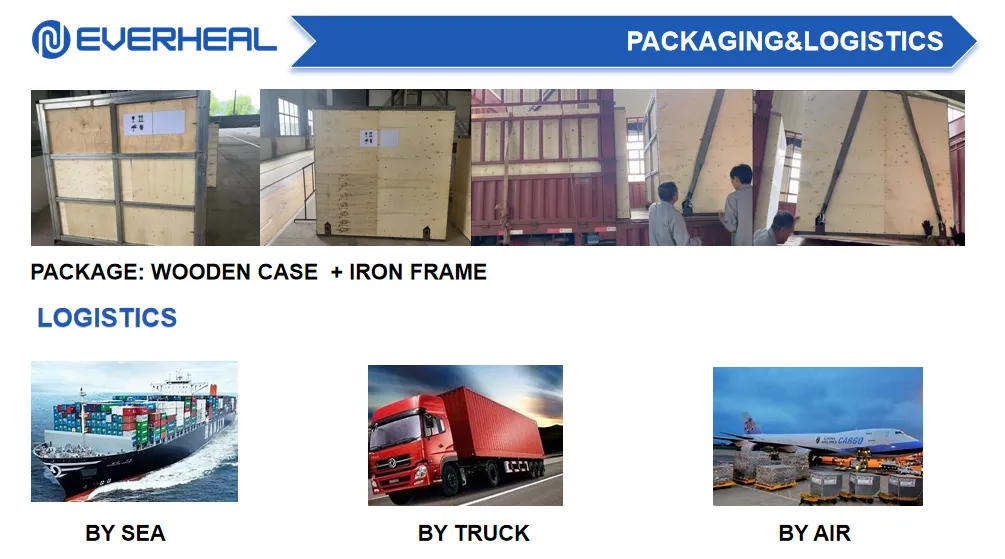

| Transport Package | Wooden Package | Specification | Customized 250L - 10000L |

| Production Capacity | Customized |

|

|

|

Key Components

RO Membrane Assembly:

Removes impurities, dissolved substances, and microorganisms from water.

PreTreatment System:

Purifies the raw water entering the reverse osmosis membrane, including the following components:

Sand Filter:

Removes suspended particles and large impurities.

Activated Carbon Filter:

Eliminates organic matter, chlorine, and odors.

Water Softener:

Removes calcium and magnesium ions from hard water.

Pressure Pump:

Provides sufficient water pressure to drive water through the reverse osmosis membrane, facilitating the osmotic process.

Control Panel:

Monitors and controls the system's operation, including water quality, flow rates, pressure, and the operation of pumps and valves.

Valves and Piping:

Controls water flow direction and pressure, ensuring proper water circulation within the system.

Automation Control System:

Real-time monitoring of water quality and system performance, automatically adjusting operational parameters to maintain consistent water quality.

2-Stage Reverse Osmosis Pure Water Purification System is an important equipment in the field of pharmaceutical manufacturing. Its primary function is to provide high-quality, pure water to meet the water quality requirements during pharmaceutical processes.

|

Key Functions and Introduction

Removal of Impurities and Microorganisms:

The system efficiently removes impurities, microorganisms, and harmful substances from the water, including bacteria, viruses, heavy metals, and chemicals, ensuring water hygiene and safety.

Production of Pharmaceutical-Grade Water:

It produces water of high purity, meeting the requirements of the pharmaceutical industry for pharmaceutical grade water. This water is suitable for critical applications such as pharmaceutical injection water, purification of drug components, and equipment cleaning.

2-Stage Reverse Osmosis Process:

Through a dual-stage reverse osmosis process, the system achieves even higher water purity, virtually free from dissolved solid residues.

Automated Control:

The equipment is typically equipped with advanced automated control systems that monitor water quality and conduct automatic reverse osmosis membrane cleaning and maintenance, ensuring continuous and stable operation.

|

Usage Scope

Pharmaceutical Companies: Used for the production of purified water, water for injection, and other pharmaceutical applications.

Hospitals and Healthcare Facilities: Utilized for preparing medical equipment, laboratory experiments, and high-purity water required for medical procedures.

Laboratories: Necessary for laboratories conducting research and experiments that require pure water.

Food and Beverage Industry: Employed in cleaning, evaporation, and beverage manufacturing processes, among various other applications.

Electronics and Semiconductor Manufacturing: Used for cleaning and etching electronic components.

Chemical Industry: Employed in chemical synthesis and experiments requiring high-purity water.

Environmental Testing Laboratories: Utilized for water quality analysis and environmental monitoring.

|

Usage Guidelines

Regular Maintenance: Perform routine cleaning and maintenance of the equipment to ensure stable performance and extended lifespan.

Compliance with Regulations: Adhere to relevant regulations and standards during usage, especially in pharmaceutical and medical fields.

Operator Training: Ensure that equipment operators receive adequate training and understand the proper operation and maintenance procedures.

Water Quality Monitoring: Regularly monitor and test the water quality to ensure it complies with the required standards and specifications.

Emergency Plans: Develop emergency plans to address potential equipment malfunctions or downtime, ensuring uninterrupted production.

|

Why Choose Us

Pharmaceutical Grade Stainless Steel Construction:

Our 2-Stage RO Pure Water Purification System is manufactured using high quality pharmaceutical grade stainless steel materials to ensure product hygiene and durability. It meets the requirements of sensitive environments such as pharmaceutical manufacturing.

Strict Manufacturing Processes and Quality Control:

We follow strict manufacturing processes and quality checks. Every device undergoes thorough testing and inspection before it's shipped to ensure it meets the pharmaceutical industry's strict standards.

Deployment of Experienced Engineers to Customer Facilities:

We dispatch experienced engineers to our customers' facilities. During the installation process, they supervise the equipment installation, ensuring that every component is correctly and accurately configured. Additionally, they provide detailed operating instructions to ensure customers can fully utilize the equipment's capabilities for efficient production.

Over 10 Years of Project Experience:

With over 10 years of successful project experience providing water purification solutions to the pharmaceutical industry,Our expertise and experience serve as strong support for the success of your projects.

|

Payment Terms

30% advance payment upon contract signing, with the remaining 70% to be settled before shipment

|

FAQ

Q: Where is your factory located?

A: Our factory is located in Ningbo, China, a port city along the East China Sea. This location ensures convenient shipping and rapid delivery worldwide.

Q: How many years of experience does your factory have?

A: Our factory has over 20 years of experience, focusing on manufacturing high-quality products and delivering solutions and services.

Q: How long is the delivery time for your products?

A: Our standard delivery time usually falls within the range of 60 to 90 days. We will provide the exact delivery time upon order confirmation. It depends on the specific product type, specifications, and order quantity.

Q: We have an overseas project. Do you have experience to provide support?

A: Yes, we have extensive overseas project experience. Please contact our sales team, and they will collaborate with you to provide engineering support and solutions, ensuring the successful implementation of your project.

Q: What after-sales service can you provide?

A: We will arrange engineers to video guide with you in the first time, if we can't solve the problem, we will arrange the service to customer site as soon as possible.

Hot Tags: 2-Stage RO Pure Water Purification System, Reverse Osmosis Pharmaceuticals, Ro Plant In Pharma Industry, Ro Water Purification System, Ro Plant For Pharmaceutical, Pharmaceutical Purified Water, Industrial Ro Water Filter System, Purified Water For Pharmaceutical Use, Purified Water System In Pharmaceutical, Pharmaceutical Water System, China, Customized, OEM, Low price, manufacturing company, manufacturers, factory, suppliers, quotation, for sale