Content Menu

● What Is an Actifil Air Filter?

● Understanding Washable Air Filters

● Are Actifil Air Filters Washable?

● How to Identify a Washable Air Filter

● The Science Behind Washable Air Filters

● Advantages of Using a Washable Air Filter

● Limitations of Washable Air Filters

● Correct Cleaning Procedure for a Washable Air Filter

● When Should You Replace an Actifil Washable Air Filter?

● Applications of Actifil Washable Air Filters

● How Washable Air Filters Support GMP Compliance

● Sustainability and Cost Perspective

● Common Misconceptions About Washable Air Filters

● Future Trends in Washable Filter Technology

● Conclusion

● FAQs

>> 1. Can all Actifil Air Filters be washed?

>> 2. How often should a washable air filter be cleaned?

>> 3. What happens if you wash a non-washable filter?

>> 4. How can I tell if my filter is washable?

>> 5. Do washable air filters affect air purity levels?

In modern industries like pharmaceuticals, biotechnology, and healthcare, one of the most critical aspects of maintaining reliable operations is air quality control. Cleanroom environments, sterile production systems, and sensitive machinery demand high-performance filtration systems. Among these, the Actifil Air Filter has built a strong reputation for reliability and performance — but a common question remains: Is an Actifil Air Filter washable?

Understanding this involves more than just a yes or no answer. It requires delving into how washable air filters work, what materials they use, and when it is practical or safe to clean and reuse them. This article offers a detailed explanation to help you make the right maintenance and purchasing choices.

What Is an Actifil Air Filter?

An Actifil Air Filter is a specialized filtration component designed to remove aerosols, particles, and microorganisms from the air stream. These filters are widely used in high-sterility industries, especially pharmaceutical manufacturing, where Everheal and other equipment suppliers rely on advanced purification systems to maintain compliance with GMP (Good Manufacturing Practice) standards.

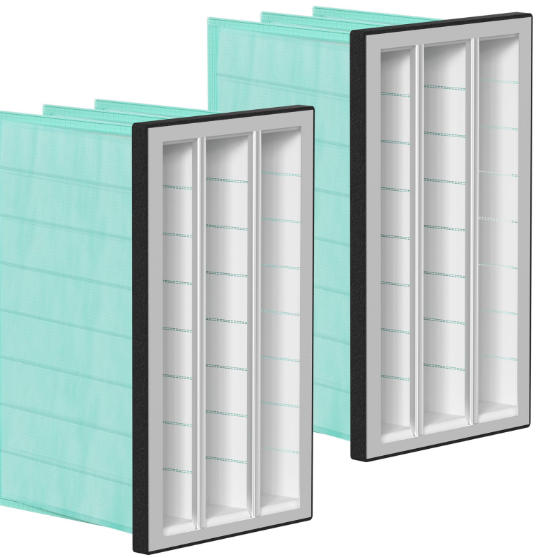

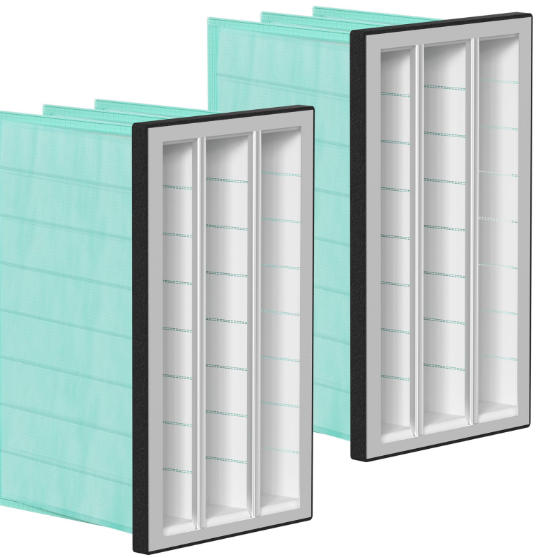

These filters are generally constructed with layers of synthetic fibers or metal meshes capable of capturing microscopic particles. The Actifil brand focuses on high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) grade filters — essential for preventing contamination in pharmaceutical cleanrooms and water preparation systems.

Understanding Washable Air Filters

A Washable Air Filter is designed to be cleaned and reused multiple times without significantly compromising its filtering efficiency. Unlike disposable filters made from fragile materials such as cellulose or paper, washable ones are commonly constructed from:

- Aluminum or stainless-steel mesh

- Synthetic polymer fibers

- Electrostatic-coated materials

These components are engineered to withstand cleaning processes, such as rinsing, backwashing, or gentle detergent washing, followed by thorough drying. The key advantage of a washable air filter is that it reduces long-term operational costs and waste, making it more sustainable and environmentally friendly.

Are Actifil Air Filters Washable?

The answer depends on the specific model and its design purpose.

Many Actifil Air Filters are *partially washable*, meaning they can be cleaned a few times before needing replacement. However, HEPA or ULPA-grade filters—which are often used in pharmaceutical cleanrooms—are generally non-washable. Washing them can damage their micro-fiber structure, reducing filtration performance and compromising cleanroom sterility.

For pre-filters or coarse filters in the Actifil series, washing may be possible and even recommended as part of routine maintenance. Yet for fine filters that use pleated designs or micro-glass fibers, wet cleaning is not advisable.

To confirm whether a specific Actifil air filter, such as the models used in Everheal's water preparation or pure steam generation systems, is washable, always refer to the manufacturer's technical manual.

How to Identify a Washable Air Filter

Determining whether an air filter can be washed safely involves checking several factors:

1. Material Type – Washable filters are usually made from washable synthetics or metals.

2. Manufacturer Labeling – Look for “washable” or “reusable” printed on the side or in the product documentation.

3. Structural Integrity – Solid frames, metallic mesh, and washable gaskets indicate reusability.

4. Service Manual – The Actifil product documentation should clearly state if wet cleaning is permitted.

5. Operating Environment – Filters exposed to oil mist, corrosive chemicals, or microbial growth may lose performance faster, even if washable.

The Science Behind Washable Air Filters

A washable air filter operates using mechanical and physical filtration principles. When air flows through it, particles are captured through:

- Interception: Small particles follow airflow streamlines and contact the fiber directly.

- Impaction: Larger particles deviate from airflow and collide with fibers.

- Diffusion: Very fine particles move randomly (Brownian motion) and get trapped.

- Electrostatic Attraction: Charged fibers attract opposite-charged particles.

Washable filters maintain efficiency by periodically removing these trapped particles through washing. However, over time, micro-pore structures can deteriorate or get clogged beyond recovery, which is why proper maintenance and replacement cycles still matter.

Advantages of Using a Washable Air Filter

Choosing a washable air filter like certain Actifil pre-filters brings several benefits:

- Cost Efficiency: Reduces replacement costs over time.

- Waste Reduction: Environmentally friendly since fewer filters are disposed of.

- Consistency: Maintains airflow and pressure stability with regular maintenance.

- Customization: Some models can be designed for specific flow rates and environments, like Everheal's pharmaceutical setups.

These advantages make washable filters ideal for systems where air cleanliness is crucial but maintenance intervals can be managed efficiently.

Limitations of Washable Air Filters

While washable filters are practical, they also come with challenges:

- Reduced Filtration Efficiency After Multiple Washes: Each cleaning cycle slightly wears down filter fibers.

- Potential for Moisture Damage: If not fully dried, moisture can foster microbial growth.

- Risk of Structural Damage: Harsh cleaning techniques or chemicals can deform filter media.

- Requires Maintenance Time: Regular washing might not suit continuous high-purity environments like sterile production areas.

Therefore, Actifil washable air filters work best when paired with disposable secondary filters or integrated into systems where downtime for maintenance is acceptable.

Correct Cleaning Procedure for a Washable Air Filter

If your Actifil model supports washing, follow this general guide:

1. Turn Off Air Flow: Always cut the air system before removing the filter.

2. Remove Filter Carefully: Avoid bending or hitting the frames.

3. Inspect Under Light: Check for physical damage or clogging.

4. Pre-Rinse With Water: Use low-pressure, lukewarm water to remove loose dust.

5. Apply Mild Detergent: Avoid acidic or basic cleaners that might degrade fibers.

6. Rinse Again Thoroughly: Ensure no soap residues remain.

7. Air Dry Completely: Do not expose the filter to direct heat or sunlight. It must be *completely dry* before reinstallation.

8. Reinstall and Test: Ensure proper sealing to prevent bypass leakage.

For optimized results, record each cleaning cycle in a maintenance log, as recommended in pharmaceutical quality control practices.

When Should You Replace an Actifil Washable Air Filter?

Even washable filters have a finite lifespan. Common indicators of replacement include:

- Persistent pressure drop after cleaning

- Visible tears, cracks, or corrosion

- Decrease in airflow efficiency

- Deformed or compressed filter media

- Contamination traces that cannot be removed

Generally, washable air filters can endure between 3 to 6 cleaning cycles before requiring replacement. Always compare post-wash performance data (like pressure differentials) to manufacturer specifications.

Applications of Actifil Washable Air Filters

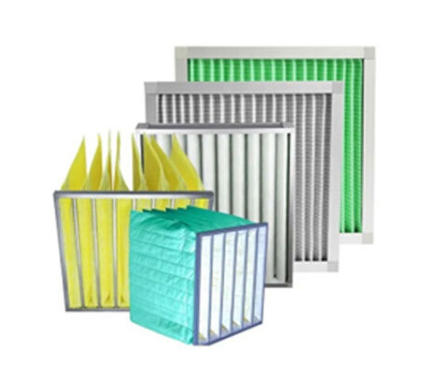

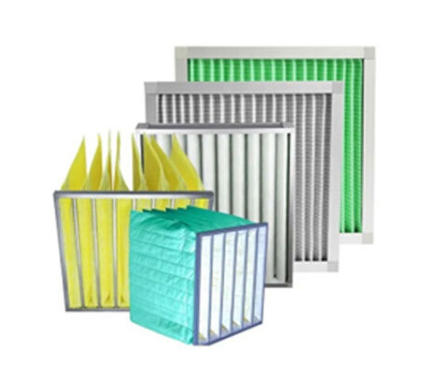

Actifil filters, including washable variants, are utilized across industries such as:

- Pharmaceuticals: In cleanroom HVAC systems, sterile filling areas, and pure water generation systems.

- Food and Beverage: For ensuring air purity during packaging and fermentation.

- Healthcare: In hospital ventilation and biosafety cabinets.

- Electronics: To protect sensitive components from particulate contamination.

- Industrial Manufacturing: Where high-dust environments demand durable, washable filters.

Everheal's integrated systems often incorporate Actifil filters for controlled environments, combining filtration with sterilization and purification processes.

How Washable Air Filters Support GMP Compliance

In sectors like pharmaceuticals, maintaining compliance with GMP and ISO cleanroom standards is crucial. Washable air filters contribute by:

- Supporting consistent airflow and pressure balance through reliable filtration.

- Allowing traceable maintenance cycles for quality assurance.

- Reducing risk of contamination through controlled cleaning procedures.

- Providing sustainable filtration aligned with environmental compliance initiatives.

Everheal integrates these standards into their custom factory layouts, ensuring that air filtration systems like the Actifil range are maintained within regulatory parameters.

Sustainability and Cost Perspective

A growing demand for sustainability has led many companies to switch from disposable to washable air filters. Over a period of five years, facilities using washable filters can save up to 40% of filtration costs, while simultaneously lowering waste disposal volumes.

For companies like Everheal that design and build entire pharmaceutical production layouts, adopting washable filters aligns with both eco-responsible manufacturing and long-term economic optimization. The reduced frequency of replacements means fewer logistical expenses and improved operational uptime.

Common Misconceptions About Washable Air Filters

There are several myths around washable filters that are worth clearing up:

- Myth 1: A washable air filter never needs replacement.

*Reality:* They have a limited reusability span.

- Myth 2: Washing restores full original efficiency.

*Reality:* Minor efficiency drops occur with each cleaning.

- Myth 3: All Actifil filters are washable.

*Reality:* Only specific models are. HEPA-grade filters are generally single-use.

- Myth 4: Any detergent can be used.

*Reality:* Only neutral or manufacturer-approved solutions are recommended.

- Myth 5: Air drying in sunlight speeds up cleaning.

*Reality:* Direct sun or heat can deform or damage filter material.

Understanding these distinctions helps users maintain filter integrity and ensures long-term performance.

Future Trends in Washable Filter Technology

The future of washable air filters is promising, with innovations including:

- Nano-coated filter surfaces for improved particle capture and water resistance.

- Self-cleaning filtration systems using reverse airflow or ultrasonic cleaning.

- Smart sensors monitoring pressure drop, humidity, and particulate load.

- Sustainable materials such as biodegradable fibers and recyclable frameworks.

Actifil and similar brands continue researching how to make filters more efficient, easier to clean, and better suited to complex systems like Everheal's steam sterilization and liquid filling machinery.

Conclusion

So, *is an Actifil Air Filter washable?*

The answer is partially yes, depending on the model and its intended application. Pre-filters and coarse filters within the Actifil range are typically washable air filters, capable of being cleaned and reused multiple times. However, advanced HEPA or ULPA filters used in strict pharmaceutical cleanrooms should not be washed, as it could compromise filtration integrity.

When managed correctly, washable air filters provide excellent cost savings, environmental benefits, and high performance for industrial and pharmaceutical systems alike. Proper cleaning methods, maintenance logging, and adherence to manufacturer guidelines ensure long-lasting, efficient air purification — a cornerstone of Everheal's commitment to reliable pharmaceutical equipment solutions.

FAQs

1. Can all Actifil Air Filters be washed?

No. Only specific Actifil models are designed as washable air filters. Always consult the product's technical datasheet or contact the manufacturer for clarification.

2. How often should a washable air filter be cleaned?

Typically every one to three months, depending on dust concentration and usage environment. In pharmaceutical cleanrooms, cleaning frequency is determined by validated maintenance schedules.

3. What happens if you wash a non-washable filter?

Washing a non-washable filter can cause fiber damage, reduced performance, and even introduce microbial risks if moisture remains trapped.

4. How can I tell if my filter is washable?

Check for durable metal or polymer construction, manufacturer instructions referencing “washable,” or reusable maintenance indicators in the manual.

5. Do washable air filters affect air purity levels?

When maintained properly, washable filters can achieve the same air purity as disposables. However, consistent monitoring is necessary to ensure compliance with GMP and ISO air standards.