Content Menu

● Understanding a Washable Air Filter

● Why Cleaning Your Washable Air Filter Matters

● Tools and Supplies You'll Need

● Step-by-Step Guide: How To Wash a Washable Car Air Filter

>> Step 1: Remove the Air Filter

>> Step 2: Inspect the Filter for Damage

>> Step 3: Apply the Cleaning Solution

>> Step 4: Rinse the Filter with Lukewarm Water

>> Step 5: Shake and Air Dry

>> Step 6: Re-Oil the Filter (If Applicable)

>> Step 7: Reinstall the Air Filter

● Professional Tips for Maintaining a Washable Air Filter

● Common Mistakes to Avoid

● Environmental and Economic Benefits

● Troubleshooting: Signs It's Time to Replace Your Washable Air Filter

● Conclusion

● FAQ: Washable Air Filter Cleaning Questions

>> 1. How often should I clean my washable air filter?

>> 2. Can I use soap or detergent to clean my washable air filter?

>> 3. What happens if I reinstall the filter before it's fully dry?

>> 4. Do all washable air filters need to be oiled?

>> 5. How long does a washable air filter last?

Maintaining your car's washable air filter is one of the simplest yet most effective ways to boost engine performance, improve fuel efficiency, and extend the lifespan of your vehicle. Unlike disposable filters, washable filters are reusable, making them cost-efficient and eco-friendly. However, proper cleaning is essential to preserve their filtration efficiency and airflow quality.

This complete guide walks you through the step-by-step process of cleaning a washable car air filter, discusses the importance of regular maintenance, and offers expert tips on drying, re-oiling, and reinstalling it correctly.

Understanding a Washable Air Filter

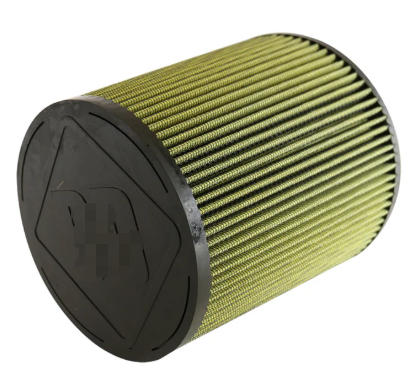

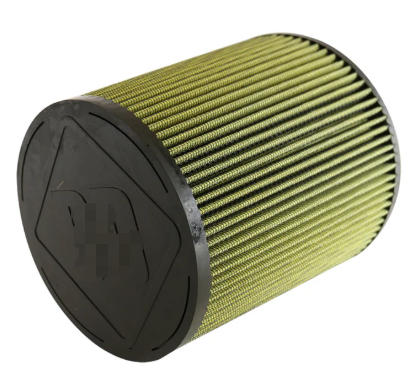

A washable air filter is designed to trap dirt, dust, pollen, and other airborne particles that could otherwise enter your engine. Unlike traditional paper filters, washable filters are made from durable materials such as cotton gauze, synthetic fibers, or foam, secured between wire meshes.

The main advantage is reusability. Once it gets dirty, instead of throwing it away, you can clean and reuse it multiple times—often up to 1 million miles with proper care. This makes it an eco-conscious and cost-saving option for vehicle owners.

Key benefits of washable air filters include:

- Improved airflow and engine performance

- Reduced long-term cost compared to disposable filters

- Eco-friendly due to lower waste generation

- Better filtration efficiency for fine dust and debris

- Compatibility with many car models and reusable designs

Why Cleaning Your Washable Air Filter Matters

Over time, the washable air filter accumulates dirt, oil residue, and microscopic particles from the atmosphere. A dirty filter restricts airflow, leading to reduced engine power and increased fuel consumption. Cleaning it restores optimal performance and ensures your vehicle runs efficiently.

Neglecting your filter can cause:

- Reduced engine horsepower

- Decreased fuel economy

- Rough idling or sluggish acceleration

- Sensor malfunctions due to poor air-fuel mixture

- Premature engine wear

Cleaning the washable air filter every 10,000–15,000 miles—or more often if you drive in dusty environments—is recommended. Always follow the manufacturer's maintenance interval to achieve the best results.

Tools and Supplies You'll Need

Before starting, prepare all the necessary cleaning materials. This ensures efficiency and prevents damage to your filter.

You'll need:

- Washable air filter cleaner (specific to your brand, such as K&N cleaner)

- Soft bristle brush (optional)

- Lukewarm water source (a bucket or gentle hose)

- Air filter oil (if applicable)

- Clean microfiber cloth

- Protective gloves

Avoid using harsh chemicals, high-pressure water, or compressed air directly on the filter element, as these can damage the filtration fibers.

Step-by-Step Guide: How To Wash a Washable Car Air Filter

Here's a comprehensive step-by-step process for cleaning your washable car air filter safely and effectively.

Step 1: Remove the Air Filter

Start by opening the air filter housing. Depending on your car model, you may need to unscrew or unclip the cover. Carefully remove the filter, taking note of its orientation so you can reinstall it correctly.

Tap the filter gently to remove loose surface dirt. Do this in an open area to avoid spreading dust inside your car's engine bay.

Step 2: Inspect the Filter for Damage

Before cleaning, examine the washable air filter for cracks, holes, or tears in the material. Damaged filters can compromise your engine's protection and should be replaced immediately.

Check the rubber seal as well—if it's dry or cracked, replace it to maintain a proper air-tight fit.

Step 3: Apply the Cleaning Solution

Spray the cleaner generously on both sides of the filter, ensuring full coverage between the pleats. Let it soak for about 10 minutes to break down grime, oil, and dust particles.

Avoid using household detergents or strong solvents. Specialized air filter cleaners are formulated to lift dirt without damaging the fibers or filter oil coating.

Step 4: Rinse the Filter with Lukewarm Water

Rinse the filter from the clean side (opposite the air intake direction) to push away contaminants. Use gentle water pressure and continue until the water runs clear.

Important tips:

- Do not use hot water, as it can deform the filter material.

- Avoid powerful jet sprays that can tear the mesh.

- Repeat the soak-and-rinse process if heavy dirt remains.

This step ensures your washable air filter regains full airflow potential.

Step 5: Shake and Air Dry

After rinsing, shake off excess water and place the filter on a clean, dry towel. Allow it to air dry naturally—do not use heat sources like hair dryers, ovens, or sunlight, as they can shrink or warp the filter media.

Drying time usually takes 6–8 hours. Ensure it's completely dry before proceeding to the next step.

Step 6: Re-Oil the Filter (If Applicable)

Some washable air filters—especially oiled cotton types—require a light coating of air filter oil after drying. This helps trap fine dust and ensures maximum filtration efficiency.

To apply:

- Shake the oil bottle and apply evenly along each pleat.

- Allow the oil to wick through for 20 minutes.

- Gently blot any excess oil using a paper towel.

Avoid over-oiling—a heavy coat can clog the filter and contaminate sensors inside the intake system.

Step 7: Reinstall the Air Filter

Ensure the washable air filter is completely dry and lightly oiled (if required). Carefully reinstall it in its original position within the housing, ensuring a tight seal.

Secure the housing cover and check for any loose fittings. Once installed, start the engine and let it idle for a minute to ensure smooth airflow and no warning lights appear.

Professional Tips for Maintaining a Washable Air Filter

Keeping your filter in perfect condition maximizes its lifespan and ensures consistent performance. Here are expert maintenance tips:

- Inspect monthly if you drive in dusty or harsh environments.

- Clean whenever you notice sluggish acceleration or increased fuel consumption.

- Never clean with compressed air—it can damage the mesh or fibers.

- Use the manufacturer's cleaner and oil kit to preserve filter integrity.

- Store spare washable filters in a dry, dust-free place.

A well-maintained washable air filter can serve your car reliably for years, reducing waste and providing superior airflow compared with disposable filters.

Common Mistakes to Avoid

Even with the right cleaning method, small errors can lead to performance issues. Here's what to avoid:

- Over-oiling the filter element

- Using harsh chemicals or dish soap

- Not drying completely before reinstalling

- Cleaning too frequently, which can wear the filter prematurely

- Forgetting to check for gasket or seal damage

Following manufacturer instructions is the best way to avoid issues and preserve your filter's efficiency.

Environmental and Economic Benefits

By using a washable air filter, you're taking a small but significant step toward sustainability. Every reusable filter prevents dozens of disposable ones from ending up in landfills. Over time, this small act contributes to cleaner manufacturing and reduced plastic waste.

Financially, it's also a smart investment. Instead of replacing a disposable filter every 15,000 miles, you pay once for a washable filter and maintain it periodically with low-cost cleaning kits.

Troubleshooting: Signs It's Time to Replace Your Washable Air Filter

While washable air filters can last for years, they're not immortal. Here are some warning signs it's time for a replacement:

- The filter's mesh or fibers are torn or permanently deformed.

- The rubber seal no longer fits tightly.

- Cleaning no longer restores original color or airflow.

- Persistent drop in fuel efficiency even after cleaning.

If you notice any of these, replacing the washable air filter is recommended to maintain proper engine protection.

Conclusion

Cleaning a washable air filter is a simple maintenance routine that delivers major benefits. It boosts engine performance, improves fuel efficiency, and saves you money over time—all while being kind to the environment.

With the right materials, care, and technique, your washable air filter can last the lifetime of your car. Follow the steps above—clean thoroughly, dry completely, re-oil (if required), and reinstall carefully—and your engine will reward you with smooth, efficient operation.

FAQ: Washable Air Filter Cleaning Questions

1. How often should I clean my washable air filter?

It's best to clean it every 10,000–15,000 miles or whenever you notice a visible layer of dirt. For drivers in dusty regions, more frequent cleaning—every 5,000–7,000 miles—is advisable.

2. Can I use soap or detergent to clean my washable air filter?

No. Regular detergents can damage the filtration media and reduce efficiency. Always use a designated washable air filter cleaner from your filter's manufacturer.

3. What happens if I reinstall the filter before it's fully dry?

Reinstalling a damp filter can cause mold growth, reduced airflow, and potential engine sensor issues. Always wait until it's 100% dry before installing.

4. Do all washable air filters need to be oiled?

Not all types require oiling. Foam and synthetic dry filters don't, while cotton gauze filters typically do. Check the manufacturer's specifications before applying oil.

5. How long does a washable air filter last?

With proper maintenance, a washable air filter can last up to 10 years or 1 million miles. However, inspect it regularly for damage to ensure continued efficiency.