Pharmaceutical Consumables Manufacturer for Compliant and Continuous Pharmaceutical Manufacturing

As a trusted Pharmaceutical Consumables Manufacturer, Everheal Group delivers high-quality consumables engineered specifically for regulated pharmaceutical manufacturing environments. Backed by a mature quality management system, comprehensive documentation capability, and stable long-term supply strategy, Everheal supports pharmaceutical companies that prioritize production continuity, audit readiness, and regulatory consistency across global markets.

Rather than positioning consumables as low-value accessories, Everheal approaches them as critical process components that directly impact product quality, validation integrity, and operational reliability. This mindset defines Everheal's role as a professional Pharmaceutical Consumables Manufacturer serving modern pharmaceutical production systems.

Pharmaceutical Consumables Designed for Regulated Manufacturing Environments

Pharmaceutical consumables are used at nearly every stage of drug manufacturing, from raw material handling and formulation to filling, packaging, and cleanroom operations. Their performance consistency and compliance status directly affect whether a production line can operate continuously under GMP conditions.

As an experienced Pharmaceutical Consumables Manufacturer, Everheal develops consumables that integrate seamlessly into validated pharmaceutical processes. Product design considers material compatibility, cleanliness level, sterility requirements, and interaction with pharmaceutical equipment systems.

Everheal's consumables are widely applied in solid dosage, liquid formulation, injectable production, and sterile processing workflows, supporting pharmaceutical manufacturers that demand predictable performance and controlled variability.

Complete Regulatory Documentation and Audit Readiness

One of the most critical requirements when selecting a Pharmaceutical Consumables Manufacturer is documentation completeness. Everheal provides full compliance documentation packages to support regulatory inspections, internal audits, and customer validation activities.

Available documentation includes certificates of analysis, material specifications, sterility and endotoxin reports where applicable, and conformity statements aligned with GMP expectations. All documents are issued under controlled quality procedures to ensure consistency across batches and over time.

This documentation framework allows pharmaceutical manufacturers to demonstrate material control, supplier qualification, and change management compliance with confidence.

Batch Traceability for Full Process Transparency

Batch-level traceability is a non-negotiable requirement in regulated pharmaceutical production. Everheal ensures that every consumable supplied can be traced back through controlled manufacturing records, raw material sources, and quality inspections.

As a responsible Pharmaceutical Consumables Manufacturer, Everheal assigns unique batch identification to consumables, enabling customers to link materials directly to production records, deviation investigations, and recall preparedness processes.

This level of traceability reduces regulatory risk and strengthens quality system robustness across the entire pharmaceutical supply chain.

Supply Stability Focused on Production Continuity

Pharmaceutical manufacturers cannot afford unexpected consumable shortages or frequent supplier changes. Everheal addresses this risk through structured production planning, safety stock management, and long-term supply agreements.

Unlike price-driven suppliers, Everheal operates as a long-term Pharmaceutical Consumables Manufacturer focused on ensuring uninterrupted availability of qualified consumables throughout the product lifecycle.

Stable supply reduces revalidation efforts, minimizes process disruptions, and allows pharmaceutical customers to maintain consistent production schedules even under fluctuating demand conditions.

Why Partner With a Long-Term Pharmaceutical Consumables Manufacturer

Choosing the right Pharmaceutical Consumables Manufacturer is a strategic decision that affects regulatory compliance, operational stability, and long-term manufacturing efficiency. Everheal positions itself as a partner rather than a transactional supplier.

As a system-aware Pharmaceutical Consumables Manufacturer, Everheal designs consumables with full consideration of their application context, including pharmaceutical water systems, preparation systems, filling lines, and cleanroom environments.

Everheal supports customer audits, supplier qualification programs, and technical documentation reviews, helping pharmaceutical companies reduce compliance workload while strengthening supply chain reliability.

By working with an experienced Pharmaceutical Consumables Manufacturer, pharmaceutical producers gain confidence that consumables will remain compliant, available, and consistent throughout extended commercial production phases.

Broad Pharmaceutical Consumables Portfolio

Everheal offers a comprehensive range of pharmaceutical consumables designed to support multiple production stages and facility zones.

1. Fluid Handling and Filtration Consumables

Consumables for fluid transfer and filtration are designed to maintain cleanliness and material compatibility while supporting controlled pharmaceutical processing.

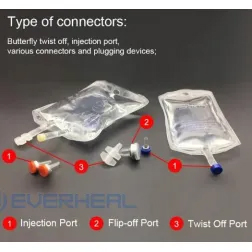

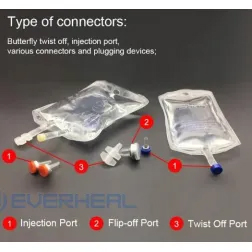

2. Single-Use Bags and Containers

These consumables support safe storage and transfer of pharmaceutical intermediates and finished liquids, with materials selected for chemical stability and cleanliness.

3. Seals, Gaskets, and Closure Components

High-precision sealing consumables ensure packaging integrity, sterility maintenance, and process reliability in filling and packaging operations.

4. Cleanroom Support Consumables

Cleanroom consumables support environmental control, contamination prevention, and operator protection within pharmaceutical manufacturing areas.

Each product category reflects Everheal's systematic approach as a professional Pharmaceutical Consumables Manufacturer rather than a generic consumables supplier.

Quality Control Embedded in Every Production Stage

Quality assurance is integrated into every phase of consumable manufacturing at Everheal. From incoming material inspection to final packaging, processes are governed by documented quality procedures and controlled environments.

This commitment allows Everheal, as a compliant Pharmaceutical Consumables Manufacturer, to deliver consumables with consistent physical properties, cleanliness levels, and performance characteristics.

For pharmaceutical manufacturers, this consistency translates into reduced deviation rates, fewer investigations, and smoother regulatory interactions.

Technical Support and System Compatibility

Everheal provides technical support to assist customers in selecting suitable consumables, integrating them into existing systems, and preparing documentation for validation or regulatory submission.

As an experienced Pharmaceutical Consumables Manufacturer, Everheal understands how consumables interact with pharmaceutical equipment, utilities, and process parameters, helping customers avoid compatibility risks and unplanned changes.

This technical collaboration strengthens long-term partnerships and improves total cost of ownership by reducing operational uncertainty.

Serving Global Pharmaceutical Manufacturers with Confidence

With international project experience and a mature quality system, Everheal supports pharmaceutical manufacturers across diverse regulatory regions. Its role as a globally trusted Pharmaceutical Consumables Manufacturer is built on consistency, transparency, and long-term reliability.

Everheal's consumables help pharmaceutical companies focus on what matters most: producing safe, effective medicines under full regulatory control.

Frequently Asked Questions

What makes Everheal a reliable Pharmaceutical Consumables Manufacturer?

Everheal combines full regulatory documentation, batch traceability, stable supply capability, and system-level understanding of pharmaceutical manufacturing requirements.

Are Everheal's pharmaceutical consumables suitable for GMP environments?

Yes. All consumables are developed and supplied under quality systems aligned with GMP expectations and regulated pharmaceutical use.

How does Everheal ensure long-term supply stability?

Through structured production planning, inventory management, and long-term cooperation strategies rather than short-term price competition.

Can Everheal support audits and supplier qualification?

Everheal provides complete documentation and technical support to assist customers during audits, inspections, and internal quality reviews.

Do Everheal's consumables integrate with pharmaceutical production systems?

Yes. Consumables are designed with system compatibility in mind, supporting pharmaceutical water, preparation, filling, and cleanroom operations.

Feel free to contact us to learn more and make your purchase!