Pharmaceutical Filling Equipment Manufacturer – Comprehensive Product Category Description

In the competitive global pharmaceutical market, selecting the right Pharmaceutical Filling Equipment Manufacturer is critical for ensuring product quality, regulatory compliance, and operational efficiency. Everheal Group, headquartered in Ningbo, China, has established itself as a trusted partner for pharmaceutical and biopharmaceutical companies worldwide, offering a robust portfolio of pharmaceutical manufacturing solutions, with an emphasis on high-precision filling equipment tailored to meet strict sterility and quality standards. With over a decade of specialized experience, Everheal's product range supports manufacturers in lowering contamination risks and achieving optimized, scalable production lines in line with current GMP Annex 1 requirements.

Understanding the Role of Pharmaceutical Filling Equipment

Pharmaceutical filling equipment forms the backbone of any liquid dosing and packaging line. These machines are engineered to transfer pharmaceutical liquids, suspensions, and other formulations into final containers such as soft bags, vials, syringes, bottles, and catheters with uncompromised accuracy and sterility. The right Pharmaceutical Filling Equipment Manufacturer not only supplies machinery but delivers engineering expertise to integrate these systems seamlessly into existing production environments while ensuring compliance with international regulatory standards.

Everheal's approach to pharmaceutical filling encompasses aseptic process design, precision metering systems, and comprehensive compatibility with multiple container types—positioning the company as an ideal solution provider for pharmaceutical, medical, and biotech manufacturers seeking reliable, high-performance filling systems.

Sterility Assurance: Minimizing Contamination Risk

One of the most important criteria for any Pharmaceutical Filling Equipment Manufacturer is the ability to maintain product sterility throughout the filling process. Everheal's portfolio is engineered with aseptic principles at the core, enabling pharmaceutical manufacturers to minimize contamination risk and support compliance with the most stringent regulatory frameworks.

Advanced filling environments offered by Everheal support ISO Class 5 or better controlled conditions and are upgradeable for enhanced cleanliness levels. Integration with vaporized hydrogen peroxide (VHP) and other decontamination systems offers manufacturers the ability to validate and maintain sterile production zones. This focus on sterility assurance ensures that products such as parenteral solutions, nutritional fluids, and injectable formulations are filled with confidence and regulatory peace of mind.

Everheal's commitment to contamination control extends beyond the machines themselves to support infrastructure such as cleanroom interfaces, automated material handling systems, and closed-loop transfer protocols that reduce personnel exposure and particulate generation—critical factors in reducing contamination risk and meeting GMP Annex 1 expectations.

Precision Filling Technology for Quality and Yield Optimization

Accuracy and repeatability are essential when filling pharmaceutical products that require exact dosages. Everheal's Pharmaceutical Filling Equipment Manufacturer pedigree includes high-precision metering systems such as peristaltic pumps, advanced volumetric fillers, and servo-driven dosing heads that consistently deliver precise fill volumes irrespective of fluid viscosity or container format.

The implementation of precision technologies directly impacts product quality and operational efficiency. Excessive overfill increases material costs and waste, while underfill can lead to compliance failures and product recalls. Everheal's filling systems are designed to maintain consistent dosing across large production volumes—supporting continuous processing with minimal deviation and optimized yield integrity.

This precise filling is especially valuable for high-value products like biologics, vaccines, and sterile injectables, where dosage consistency is non-negotiable and product loss must be minimized.

Adapting to Different Dosage Forms and Container Types

Pharmaceutical manufacturers often produce a wide array of dosage forms and packaging formats, requiring filling systems that are adaptable and flexible. Everheal's Pharmaceutical Filling Equipment Manufacturer solutions address these diverse needs with machines capable of handling:

* Soft Bag Formats: Ideal for IV fluids, nutritional solutions, and blood-related products, with specialized mechanisms to secure bag integrity and sterile handling throughout the fill and seal process.

* Vials and Ampoules: Engineered for aseptic vial filling and crimping, supporting glass and compatible plastic formats with customizable heads and modular layouts.

* Pre-Filled Syringes and Catheters: Vacuum filling and stoppering machines designed for pre-filled devices that demand both accuracy and sterility.

* Bottles and Liquid Containers: Snap cap and automated capping systems that streamline the transition from fill to final closure.

* Powder and Specialty Liquids: Multi-lane powder packing and liquid packing machines that expand capabilities beyond traditional liquid dosing to include complex formulations.

This adaptability allows manufacturers to consolidate equipment suppliers and simplifies qualification, validation, and changeover processes across multiple product lines.

Core Product Categories within Everheal's Filling Equipment Line

Everheal's product range under the Pharmaceutical Filling Equipment category includes, but is not limited to:

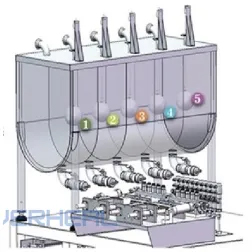

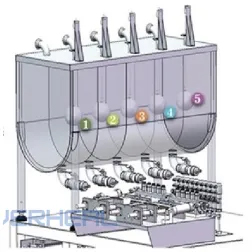

IV Soft Bag Filling Machines

Designed for aseptic handling of intravenous fluids, these machines integrate controlled filling environments, leak detection systems, and universal bag handling features ensuring compliance and adaptability for different soft bag formats.

Vial Filling and Crimping Systems

These systems provide automated filling solutions that align vial washing, accurate dosing, and secure sealing into one coherent process, catering to the demands of sterile injectables and sensitive solutions.

Pre-Filled Syringe Systems

Offering precision vacuum filling and sealing mechanisms, these machines are optimized for the efficient handling of syringe formats that support vaccines, biologics, and high-throughput sterile product lines.

Bottle Filling and Snap Capping Machines

Integrating advanced capping and closure solutions, these lines are ideal for oral liquids, syrups, and non-sterile formulations, supporting streamlined downstream packaging.

Specialized Powder & Liquid Packaging Lines

Multi-lane packing solutions offer enhanced throughput and versatile product handling, empowering manufacturers to extend their production capabilities.

Enhancing GMP Compliance and Operational Efficiency

As a Pharmaceutical Filling Equipment Manufacturer, Everheal places a strong emphasis on delivering systems that are not only technically superior but also supportive of regulatory compliance and lifecycle performance. These are engineered with features that facilitate cleaning, sterilization, and validation:

* Clean-In-Place (CIP) and Sterilize-In-Place (SIP) capabilities

* 316L stainless steel product contact surfaces with electropolished finishes

* Tool-free change parts for rapid format changeovers

* Smart, digital control interfaces with data monitoring and traceability

These design principles help lower contamination risk, enhance operational transparency, and support documentation standards required for audits and inspections—boosting confidence in product quality and adherence to GMP Annex 1.

Global Service and Lifecycle Support

Choosing the right Pharmaceutical Filling Equipment Manufacturer goes beyond initial procurement. Everheal provides robust after-sales support, including installation, validation documentation (DQ, IQ, OQ, PQ), maintenance services, and remote diagnostics that help pharmaceutical partners maintain uptime and performance throughout the equipment lifecycle.

Frequently Asked Questions

1. What types of pharmaceutical containers can Everheal's filling equipment handle?

Everheal's filling equipment expertly accommodates soft bags, vials, pre-filled syringes, and bottles, offering broad applicability across formulation types.

2. How does Everheal ensure sterilization during the filling process?

Their equipment is designed for aseptic zones with integrated decontamination compatibility, closed-loop transfer systems, and controlled environments to maintain sterility.

3. Can Everheal's filling systems be customized to specific production needs?

Yes, customization options are available for container sizes, volume ranges, and process integration to align with unique manufacturer requirements.

4. Are these filling machines compliant with global pharmaceutical regulations?

Everheal's filling solutions are engineered to support compliance with GMP, EU Annex 1, and other international standards.

5. What support is provided after equipment installation?

Everheal offers comprehensive lifecycle support, including installation assistance, validation documentation, maintenance and repair services, and remote troubleshooting.

Everheal's position as a Pharmaceutical Filling Equipment Manufacturer combines engineering innovation, precision performance, and regulatory confidence—making it a strategic partner for pharmaceutical manufacturers aiming to strengthen production integrity and streamline their operations.

Feel free to contact us(Pharmaceutical Filling Equipment Manufacturer) to learn more and make your purchase!