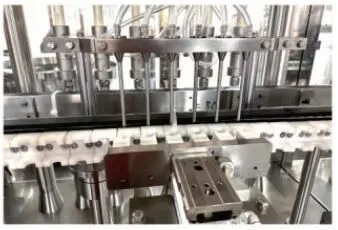

Pre-filled Catheter Flusher Filling Line is widely applicable to various types of pre-filled catheter flushers, with customization available for special types of syringes.

The surface is made of SUS304 stainless steel, and contact parts are crafted from SUS316L stainless steel and medical-grade silicone rubber, meeting GMP specifications.

The equipment is equipped with self-cleaning platforms for both rubber plugs and caps, allowing for uninterrupted addition of plugs and caps.

Silicone coating utilizes a high-precision ultra-micro misting valve from Japan, offering adjustable spray volumes between 0.5-2 milligrams with high accuracy, stability, no overspray, and no dripping.

Ceramic piston pumps enable precise filling, resistant to acid and alkali corrosion, wear, and high temperatures, ensuring high filling accuracy.

Sorting and conveying of rubber plugs and caps are achieved through a vibrating disc with a SUS316L stainless steel clean disc, eliminating cleaning dead spots. The top disc is detachable and supports sterilization.

International renowned brand electrical components are used, implementing interference-free modular control. All synchronized movements are controlled by servo motors for accuracy, reliability, and ease of operation.

Motor operations are controlled by a PLC programming controller, and the human-machine interface monitors and displays the working status of each station in real-time, providing automatic alarms and fault location display.

Multiple filling doses and methods are available, supporting the storage of various formula parameters.

Fully automatic operation covers material handling, loading, siliconization, plug insertion, filling, capping, rejection, and more.

Optional automatic replenishment system uses liquid level sensing for automatic refilling when materials are low.

Optional Class A laminar flow hood enables high-quality clean production.

| Applicable Materials | Liquid and Gel |

| Applicable Specifications | Pre-filled Catheter Flushers |

| Filling Range | 0.1-30ml(Requires change of plunger pump) |

| Number of Filling Needles | 6 |

| Filling Accuracy | ≤±1.5% |

| Production Capacity | 9000-10000 units/hour |

| Total Power | 12KW |

| Voltage | 380V 50Hz |

| Compressed Air | 0.6-0.7Mpa |

| Dimensions | L7118×W2750×H2030mm |

| Total Weight | 2900KG |

Pharmaceutical Grade Stainless Steel Construction:

Manufactured using high quality pharmaceutical grade stainless steel materials to ensure product hygiene and durability. It meets the requirements of sensitive environments such as pharmaceutical manufacturing.

Strict Manufacturing Processes and Quality Control:

We follow strict manufacturing processes and quality checks. Every device undergoes thorough testing and inspection before it's shipped to ensure it meets the pharmaceutical industry's strict standards.

Deployment of Experienced Engineers to Customer Facilities:

We dispatch experienced engineers to our customers' facilities. During the installation process, they supervise the equipment installation, ensuring that every component is correctly and accurately configured. Additionally, they provide detailed operating instructions to ensure customers can fully utilize the equipment's capabilities for efficient production.

Over 10 Years of Project Experience:

With over 10 years of successful project experience providing water purification solutions to the pharmaceutical industry,Our expertise and experience serve as strong support for the success of your projects.

Payment Terms:

30% advance payment upon contract signing, with the remaining 70% to be settled before shipment

Hot Tags: Pre-Filled Catheter Flusher Filling Line, Syringe Filling Machine, Prefilled Syringe Filling Machine, Automated Syringe Filler, Automatic Filling Equipment, Catheter Flusher Filling Line, Syringe Filling Equipment, Syringe Assembly Machine, Semi Automatic Filling Machine, Liquid Filling Equipment, China, Customized, OEM, Low price, manufacturing company, manufacturers, factory, suppliers, quotation, for sale