Content Menu

● What Is a Washable Air Filter?

● Why Knowing Your Filter Type Matters

● Key Signs That You Have a Washable Air Filter

>> 1. Construction Material

>> 2. Presence of a Cleaning Label or Marking

>> 3. Filter Media Thickness and Flexibility

>> 4. Absence of Replace-By Dates

>> 5. Manufacturer and Model Information

● How Washable Air Filters Work

● Benefits of a Washable Air Filter

● How to Maintain a Washable Air Filter

>> Step 1: Turn Off the System

>> Step 2: Remove the Filter Carefully

>> Step 3: Pre-Rinse With Water

>> Step 4: Clean With a Mild Detergent

>> Step 5: Rinse and Dry Completely

>> Step 6: Inspect for Wear

● Common Mistakes to Avoid

● Washable vs. Disposable Air Filters

● When to Replace a Washable Air Filter

● Conclusion

● FAQ

>> 1. How often should I clean a washable air filter?

>> 2. Can I use soap to clean a washable air filter?

>> 3. What happens if I reinstall a damp washable air filter?

>> 4. Are washable air filters as effective as disposable ones?

>> 5. How long does a washable air filter typically last?

Air quality plays a vital role in maintaining a healthy environment for both residential and industrial spaces. One of the most overlooked yet essential components of air quality management is the air filter. Filters remove dust, pollen, mold, bacteria, and other impurities from the air, ensuring that systems—whether heating, ventilation, or air conditioning (HVAC)—run efficiently.

However, not all air filters are the same. Some require regular replacement, while others can be washed and reused multiple times. For business owners, engineers, and facility managers—especially in the pharmaceutical and industrial equipment sectors such as Everheal's—understanding the difference between a washable air filter and a disposable one can lead to major cost savings and improved process reliability.

In this article, we'll help you determine whether you have a washable air filter, how it works, and how to maintain it properly.

What Is a Washable Air Filter?

A washable air filter, also known as a reusable air filter, is designed to be cleaned and reused instead of discarded after a single use. Unlike standard disposable filters made from fiberglass or pleated paper, washable filters are constructed from durable materials such as aluminum mesh, electrostatic foam, or stainless-steel fabric. These materials can withstand repeated washing and drying cycles without losing their filtration efficiency.

Washable filters are commonly found in:

- HVAC systems for residential homes

- Industrial ventilation units

- Pharmaceutical manufacturing cleanrooms

- Laboratory equipment and service rooms

- Food processing and packaging systems

Their robust design aligns perfectly with Everheal's philosophy of ensuring long-term efficiency and sustainability in pharmaceutical production environments.

Why Knowing Your Filter Type Matters

Recognizing whether you have a washable air filter or a disposable one is more than a minor detail—it directly impacts:

- Operational costs: Replacing disposable filters frequently can be expensive over time. Washable filters offer a one-time purchase cost but lower maintenance costs.

- System efficiency: Using the wrong filter type or neglecting maintenance can cause airflow obstructions, increased energy consumption, or even mechanical wear.

- Compliance: In pharmaceutical and industrial settings, air quality must meet strict regulatory standards. Knowing your filter type ensures process consistency.

Understanding the characteristics of washable filters also helps prevent accidental damage, especially if you mistakenly attempt to wash a non-washable filter.

Key Signs That You Have a Washable Air Filter

Identifying a washable air filter can be simple once you know what to look for. Here are several indicators:

1. Construction Material

Check the material of your air filter. Washable air filters are typically made of metal frames (aluminum or stainless steel) rather than cardboard, which is common in disposables. Inside the frame, you might see layers of fine metal mesh or foam. These materials are resistant to moisture and cleaning agents.

2. Presence of a Cleaning Label or Marking

Most washable air filters come with a manufacturer label or printed instructions like:

*“Wash and Reuse,” “Rinse with Water,” or “Reusable Air Filter.”*

If you find these markings anywhere on the frame or packaging, your filter is washable.

3. Filter Media Thickness and Flexibility

Washable filters are usually thicker and more rigid compared to disposable ones. The filter layers often feel sturdier, as they're built to withstand handling during cleaning. If the filter bends easily or seems paper-like, it's likely disposable.

4. Absence of Replace-By Dates

Disposable filters commonly display a recommended replacement date or operating hours (for example, “Replace every 3 months”). Washable filters, instead, will instruct when to clean, such as “Clean every 6 weeks” or “Rinse monthly.”

5. Manufacturer and Model Information

Search online using the filter's model number or brand name—most manufacturers specify whether a filter is washable. Reputable suppliers, including HVAC and industrial equipment manufacturers, list this information clearly.

How Washable Air Filters Work

A washable air filter functions using either electrostatic charge or mechanical filtration:

- Electrostatic filters use static electricity to attract and trap airborne particles. As air passes through the filter's charged layers, dust and impurities cling to the media surfaces.

- Mechanical filters rely on physical barriers (metal mesh or foam) to catch particles of different sizes.

Both types can be cleaned with water or mild detergents, restoring their filtration performance. This makes them particularly useful in industries—like pharmaceuticals—where clean air is critical but filters must handle continuous use.

Benefits of a Washable Air Filter

The advantages of using a washable air filter go beyond reduced replacement costs. Below are key benefits for both homes and industrial facilities:

- Cost-effective long-term solution: While initial purchase costs are higher, they quickly pay for themselves through reuse.

- Environmentally friendly: Reusable filters reduce landfill waste.

- Consistent performance: Designed for stable airflow and filtration efficiency across multiple cleaning cycles.

- Reduced supply chain dependency: Less reliance on recurring filter deliveries—especially valuable for high-security industries.

- Tailored fit for specialized environments: In pharmaceutical equipment, washable filters can be customized to specific airflow or purity standards.

How to Maintain a Washable Air Filter

Regular maintenance keeps your washable air filter functioning optimally. Here's how to do it correctly:

Step 1: Turn Off the System

Always power down your HVAC unit, cleanroom unit, or other ventilation equipment before removing the filter to avoid injury or accidental contamination.

Step 2: Remove the Filter Carefully

Detach the filter gently from its housing. Avoid bending the frame, as metal filters can warp under excessive pressure.

Step 3: Pre-Rinse With Water

Rinse the filter under lukewarm water to remove loose dust and particles. A low-pressure hose is ideal to prevent damaging the mesh.

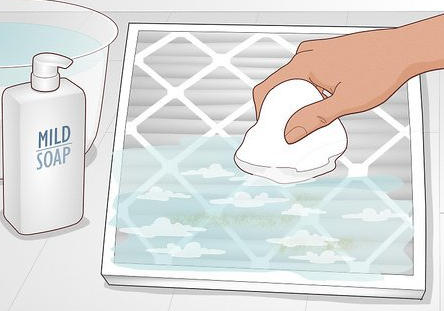

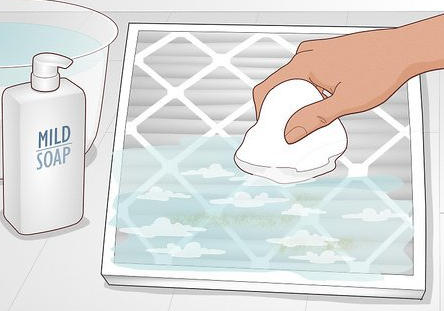

Step 4: Clean With a Mild Detergent

For more stubborn dust or oil residue (common in industrial systems), soak the filter in a mild detergent solution for 10–15 minutes. Never use harsh chemicals unless the manufacturer specifically allows it.

Step 5: Rinse and Dry Completely

Shake off excess water, then allow the filter to dry naturally. Never reinstall a damp filter, as retained moisture can promote bacterial growth or corrosion.

Step 6: Inspect for Wear

Before reinstalling, ensure the filter frame and media remain intact without holes or warping. Damaged parts should be repaired or replaced.

Regular cleaning intervals vary—residential systems may need washing every 1–3 months, while industrial systems may require shorter intervals depending on air quality and workload.

Common Mistakes to Avoid

Even high-quality washable air filters can fail early if not handled correctly. Avoid these errors:

- Using high-pressure water that can damage or tear filter media.

- Reinstalling the filter before it's totally dry, leading to microbial growth.

- Ignoring scheduled maintenance, resulting in airflow blockage.

- Using abrasive cleaning agents or solvents.

- Washing a disposable filter by mistake, which can permanently damage your HVAC system.

Proper maintenance ensures the filter continues to deliver reliable air purification over many years.

Washable vs. Disposable Air Filters

Here's a quick comparison:

| Feature | Washable Air Filter | Disposable Air Filter |

| Material | Metal mesh or foam | Fiberglass or pleated paper |

| Lifespan | 5–10 years | 1–3 months |

| Cost over time | Lower | Higher |

| Maintenance | Requires washing | Requires replacement |

| Eco-friendliness | Reusable, less waste | Single-use, more waste |

| Use cases | HVAC, cleanrooms, industrial systems | Basic home or office use |

For sustainable operations, washable filters are generally the smarter choice—especially where air quality and cost efficiency are priorities.

When to Replace a Washable Air Filter

Although washable air filters last longer, they are not indestructible. Signs that it's time for a replacement include:

- Visible damage such as torn mesh or bent frames.

- Reduced airflow even after cleaning.

- Residual odor that persists after washing.

- Deteriorated metal or corroded sections.

Typically, a well-maintained washable filter can serve for up to 10 years, depending on its environment and material quality.

Conclusion

Knowing whether you have a washable air filter can significantly impact both maintenance costs and air quality outcomes. By recognizing the materials, labels, and construction of your filter, you'll ensure proper upkeep and extend the life of your HVAC or manufacturing system. Whether you're operating home ventilation or specialized pharmaceutical equipment, washable filters deliver durability, efficiency, and sustainability that disposables can't match.

Taking time to identify and maintain your washable air filter helps protect not only your system but also the purity and safety of your environment—values at the heart of advanced equipment solutions like those designed by Everheal.

FAQ

1. How often should I clean a washable air filter?

It's best to clean it every 1–3 months for residential use and more frequently in industrial environments, depending on exposure to dust and contaminants.

2. Can I use soap to clean a washable air filter?

Yes, but only mild detergents should be used. Avoid strong solvents or bleach, as they can damage filter materials or coatings.

3. What happens if I reinstall a damp washable air filter?

Installing a damp filter can cause mold growth, rust, and air blockage. Always ensure complete drying before reinstallation.

4. Are washable air filters as effective as disposable ones?

When properly maintained, washable filters offer similar or even superior performance, especially for large-particle filtration and long-term cost efficiency.

5. How long does a washable air filter typically last?

A well-maintained washable air filter can last 5–10 years or longer, depending on material quality and proper cleaning practices.