Pharmaceutical Preparation System Manufacturer – Everheal Group Comprehensive Product Overview

Company Overview and Commitment to Quality

Everheal Group, officially Ningbo Everheal Medical Equipment Co., Ltd., is a trusted Pharmaceutical Preparation System Manufacturer based in Ningbo, China, with over 15 years of experience in supplying advanced pharmaceutical equipment and turnkey solutions to global clients. As a globally oriented Pharmaceutical Preparation System Manufacturer, the company focuses on engineering reliability, regulatory compliance, and long-term operational stability. Everheal's product range supports the full pharmaceutical production lifecycle—from water treatment to preparation, filling, and sterilization systems—ensuring high-quality and consistent output for pharmaceutical manufacturers worldwide.

In particular, Everheal's Pharmaceutical Preparation System category is designed to ensure excellent process controllability, batch-to-batch consistency, and deep integration with automated CIP/SIP cleaning and sterilization protocols. These capabilities reinforce Everheal's positioning as a solution-driven Pharmaceutical Preparation System Manufacturer serving formulation plants, sterile production facilities, and GMP-compliant pharmaceutical factories.

Why the Pharmaceutical Preparation System Matters

Core Role of Preparation Systems in Pharmaceutical Manufacturing

A Pharmaceutical Preparation System lies at the core of formulation and compounding operations, acting as the critical interface between raw materials and finished dosage forms. From purified water and solvents to APIs and excipients, all inputs must be processed under strictly controlled conditions. For this reason, choosing a capable Pharmaceutical Preparation System Manufacturer directly impacts final product quality, regulatory compliance, and production efficiency.

Everheal designs preparation systems that enable pharmaceutical manufacturers to standardize formulation steps, eliminate variability, and maintain consistent quality across production batches. By embedding automation logic, precision measurement, and validated process control into every system, Everheal ensures that preparation is no longer a weak point but a strength within the overall production chain.

Key Design Philosophy of Everheal Pharmaceutical Preparation Systems

1. Process Controllability as the Foundation

Process controllability is the defining factor of a reliable preparation system. Everheal integrates advanced instrumentation, automated valves, and programmable control units to allow pharmaceutical manufacturers to precisely manage mixing speed, temperature, pressure, and liquid transfer rates. As a professional Pharmaceutical Preparation System Manufacturer, Everheal emphasizes repeatable and traceable process execution rather than manual dependency.

This approach allows operators to reproduce validated processes with confidence, ensuring that each preparation cycle meets predefined quality parameters. Tight process control not only protects product integrity but also simplifies validation and audit procedures.

2. Ensuring Batch-to-Batch Consistency

Batch inconsistency is one of the most common risks in pharmaceutical manufacturing. Variations during preparation can propagate downstream, affecting filling accuracy, stability, and shelf life. Everheal addresses this challenge through standardized system architecture and automation-driven repeatability.

As an experienced Pharmaceutical Preparation System Manufacturer, Everheal engineers its systems to deliver homogeneous mixing, stable thermal conditions, and controlled material addition sequences. These features significantly reduce batch deviation and help pharmaceutical companies maintain uniform quality across long-term production campaigns.

Core Equipment within the Pharmaceutical Preparation System Category

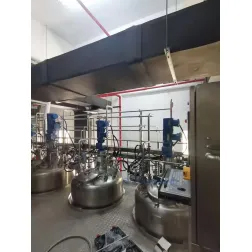

1. Pharmaceutical Mixing Tank Systems

Everheal's pharmaceutical mixing tank systems are designed for high-purity liquid preparation, solution blending, and suspension processing. Manufactured with sanitary-grade materials and smooth internal finishes, these tanks support GMP-compliant production requirements. Integrated agitation systems and real-time monitoring instruments allow for precise control over formulation dynamics.

By offering configurable volumes and automation levels, Everheal reinforces its role as a flexible Pharmaceutical Preparation System Manufacturer capable of supporting both pilot-scale and commercial-scale operations.

2. Pharmaceutical Dispensing and Transfer Systems

Accurate dispensing is essential for maintaining formulation integrity. Everheal's dispensing systems enable precise dosing and controlled transfer of prepared solutions to downstream processes. Automated measurement and closed-loop control minimize human error while improving operational efficiency.

These dispensing solutions further demonstrate Everheal's expertise as a Pharmaceutical Preparation System Manufacturer focused on reliability, precision, and long-term production stability.

Automation and CIP/SIP Integration

1. Automation-Driven Production Efficiency

Automation is no longer optional in modern pharmaceutical plants. Everheal designs its preparation systems to integrate seamlessly with centralized control platforms, enabling real-time monitoring, data recording, and alarm management. This level of automation enhances transparency and allows pharmaceutical manufacturers to optimize production scheduling and resource utilization.

By embedding automation into preparation workflows, Everheal strengthens its competitive advantage as a technology-oriented Pharmaceutical Preparation System Manufacturer supporting digitalized pharmaceutical manufacturing environments.

2. CIP and SIP Compatibility for Hygienic Design

Cleaning in Place and Sterilization in Place functions are essential for maintaining aseptic conditions and minimizing cross-contamination risks. Everheal's preparation systems are fully compatible with CIP and SIP procedures, allowing internal surfaces to be cleaned and sterilized automatically without disassembly.

This design reduces downtime between batches, improves operator safety, and supports regulatory compliance—key factors for pharmaceutical manufacturers selecting a dependable Pharmaceutical Preparation System Manufacturer.

Custom Engineering and Project-Oriented Solutions

Everheal understands that no two pharmaceutical facilities are identical. As a project-capable Pharmaceutical Preparation System Manufacturer, the company provides customized system design based on product characteristics, capacity requirements, and plant layout constraints. From concept design to installation and commissioning, Everheal supports customers throughout the entire project lifecycle.

This solution-oriented approach ensures that preparation systems are not only technically sound but also economically efficient and scalable for future expansion.

Value for B2B Pharmaceutical Manufacturers

For pharmaceutical manufacturers, the preparation system is a decisive factor in determining overall production quality. Everheal's systems help customers achieve:

* Stable and controllable formulation processes

* High batch-to-batch reproducibility

* Reduced manual intervention and operational risk

* Efficient CIP/SIP cleaning and sterilization

* Long-term compliance with GMP standards

By choosing Everheal as a Pharmaceutical Preparation System Manufacturer, pharmaceutical companies gain a reliable partner committed to process stability and quality consistency.

Frequently Asked Questions

1. What is included in a Pharmaceutical Preparation System?

A Pharmaceutical Preparation System typically includes mixing tanks, dispensing units, transfer pipelines, control systems, and CIP/SIP interfaces designed for pharmaceutical liquid formulation.

2. Why is process controllability critical in preparation systems?

Because preparation directly affects formulation accuracy and consistency, precise control of parameters ensures stable product quality and regulatory compliance.

3. How does automation improve batch consistency?

Automation standardizes process execution, reduces operator dependency, and ensures repeatable production conditions across batches.

4. Can Everheal customize preparation systems for different products?

Yes. Everheal provides customized engineering solutions based on formulation characteristics, production scale, and facility requirements.

5. How does CIP/SIP integration benefit pharmaceutical plants?

CIP/SIP integration enables efficient cleaning and sterilization, reduces downtime, and minimizes contamination risks between production batches.

Feel free to contact us to learn more and make your purchase!