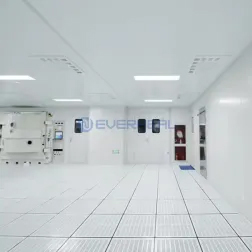

Cleanroom Engineering And Products Designed for Regulatory Compliance

As an experienced Cleanroom Engineering And Products Manufacturer, Everheal Group delivers more than cleanroom construction. We provide fully engineered, GMP-compliant controlled environment systems designed to pass regulatory audits and support long-term pharmaceutical and life-science production.

In regulated industries, a cleanroom is not an interior project. It is a validated environmental control system where air cleanliness, pressure hierarchy, temperature, humidity, and operational workflows must work together as one certifiable unit. As a professional Cleanroom Engineering And Products Manufacturer, Everheal focuses on engineering reliability, compliance readiness, and lifecycle performance rather than surface-level installation.

From Cleanroom Space to GMP-Ready Environmental System

1. GMP Cleanliness Grades Built into the Engineering Logic

Every cleanroom solution begins with GMP classification planning. As a Cleanroom Engineering And Products Manufacturer, Everheal designs systems aligned with GMP Grade A, B, C, and D requirements, ensuring that cleanliness levels are achieved through airflow design, pressure differentials, and filtration efficiency rather than after-the-fact adjustments.

Our engineering philosophy ensures that compliance is embedded in the system architecture, enabling stable performance during routine operation and regulatory inspection.

2. Environmental Control as a System, Not Individual Equipment

True cleanroom performance depends on coordination. Everheal integrates HVAC systems, airflow patterns, temperature and humidity control, and pressure zoning into a unified platform. This system-level approach is what distinguishes a reliable Cleanroom Engineering And Products Manufacturer from conventional contractors.

Environmental stability supports product quality, operator safety, and regulatory consistency across the full production cycle.

Core Cleanroom Engineering And Products Portfolio

As a full-scope Cleanroom Engineering And Products Manufacturer, Everheal supplies and integrates all essential components required for certified cleanroom environments.

1. Cleanroom Architectural Systems

Our cleanroom panels, ceilings, doors, and observation windows are engineered for low particle emission, chemical resistance, and cleanability. These architectural products form the physical containment system required to maintain GMP cleanliness over time.

All materials are selected to support long-term compliance, not just initial certification.

2. Air Handling and Filtration Systems

Air cleanliness is achieved through carefully engineered air handling units combined with HEPA or ULPA filtration. As a Cleanroom Engineering And Products Manufacturer, Everheal designs airflow systems that maintain unidirectional flow, stable air changes per hour, and reliable pressure cascades between cleanroom zones.

These systems minimize contamination risks while supporting operational efficiency.

3. Cleanroom Auxiliary Products and Utilities

Everheal provides a complete range of cleanroom auxiliary systems, including air showers, pass boxes, transfer hatches, and environmental monitoring interfaces. These Cleanroom Engineering And Products ensure controlled personnel and material flow while supporting GMP documentation requirements.

Utilities are integrated to function seamlessly within the cleanroom environment.

Engineering Capability Beyond Installation

1. Cleanroom Engineering Focused on Process Logic

As a Cleanroom Engineering And Products Manufacturer, Everheal designs cleanrooms around process flow, not floor plans alone. Personnel movement, material entry, waste removal, and equipment placement are all engineered to support contamination control and audit transparency.

This process-driven design reduces operational risks and improves long-term compliance.

2. Customization for Different Regulated Industries

Different industries demand different environmental tolerances. Everheal customizes Cleanroom Engineering And Products for pharmaceutical manufacturing, biotechnology, medical devices, and laboratory applications, aligning cleanroom systems with specific regulatory and operational needs.

Customization ensures that each system remains both compliant and practical.

Validation-Ready Delivery and Documentation Support

1. Cleanroom Systems Designed to Pass Inspection

Validation is not an afterthought. Everheal delivers Cleanroom Engineering And Products that are designed from the beginning to support IQ, OQ, and PQ requirements. System parameters are measurable, controllable, and documentable.

As a Cleanroom Engineering And Products Manufacturer, we focus on delivering environments that are inspection-ready at handover.

2. Structured Documentation and Commissioning Support

Engineering drawings, equipment specifications, testing protocols, and commissioning records are provided to support regulatory review. This documentation framework reduces approval timelines and simplifies future audits.

Clients receive not just a cleanroom, but a validated system with traceable engineering logic.

Why Everheal Is a Trusted Cleanroom Engineering And Products Manufacturer

1. Engineering-Driven, Not Decoration-Driven

Everheal approaches cleanroom projects as engineering systems, not construction projects. This mindset ensures performance stability, regulatory consistency, and predictable outcomes.

2. Integrated Delivery Model

By combining design, product supply, system integration, and validation support, Everheal reduces coordination risks and accelerates project timelines.

3. Long-Term Compliance Focus

As a Cleanroom Engineering And Products Manufacturer, Everheal designs for years of compliant operation, not short-term acceptance. Systems are scalable, maintainable, and adaptable to evolving regulatory requirements.

Cleanroom Engineering And Products for B2B Decision Makers

For pharmaceutical manufacturers, investors, and engineering teams, selecting the right Cleanroom Engineering And Products Manufacturer directly impacts approval success, production efficiency, and operational risk.

Everheal delivers certifiable cleanroom environment systems that align engineering precision with regulatory expectations — supporting confident investment and sustainable production.

Frequently Asked Questions

What does a Cleanroom Engineering And Products Manufacturer actually deliver?

A manufacturer delivers integrated cleanroom systems that control air quality, pressure, temperature, and contamination to meet GMP and regulatory standards.

Why is cleanroom engineering more important than cleanroom construction?

Because compliance depends on environmental performance and validation, not visual appearance.

Can Everheal support GMP certification and audits?

Yes. Everheal provides engineering designs, testing support, and documentation aligned with GMP inspection requirements.

Are Everheal cleanrooms customizable for different products?

Absolutely. Cleanroom Engineering And Products are customized based on process flow, risk level, and regulatory classification.

Is Everheal suitable for international pharmaceutical projects?

Yes. Everheal's systems are designed to align with global GMP standards and international regulatory expectations.

Feel free to contact us to learn more and make your purchase!