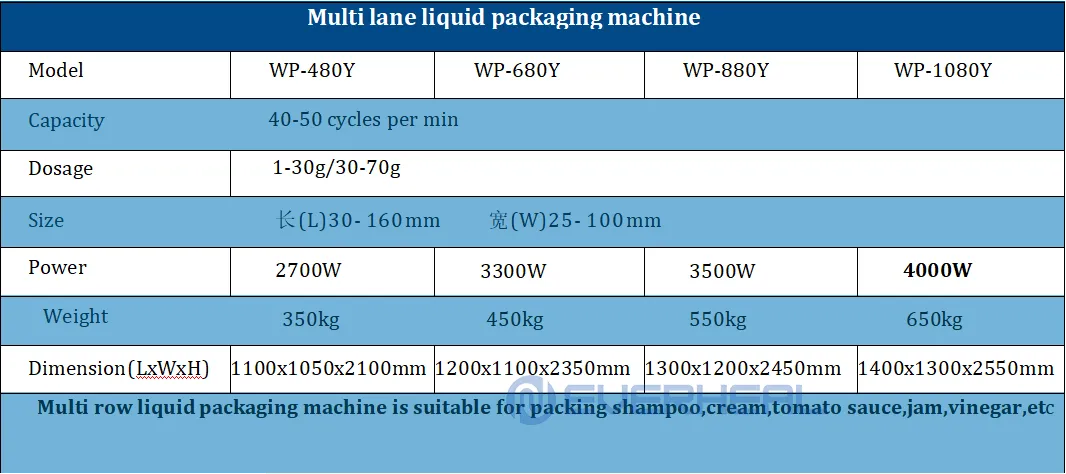

|

Key Advantages of Our Product

High Production Efficiency: The multi-lane design enables our liquid packing machine to concurrently handle multiple products, significantly boosting production efficiency.

Precision Packaging: With high-speed packaging capabilities, it ensures precise packaging, maintaining top-tier quality consistently.

Versatile Applications: Suitable for a variety of liquid products, including beverages, condiments, and cosmetics, enhancing product adaptability.

Advanced Technology: Incorporating the latest technology, our equipment guarantees outstanding performance and reliability, elevating the modernization of your production processes.

User-Friendly Operation: Designed with a user-friendly interface, the machine's operation is simple and intuitive, reducing operational complexity.

Reliability Assurance: Rigorous testing and quality control ensure the stability and reliability of the equipment, minimizing maintenance costs.

Competitive Edge: Adopting this advanced solution enhances your competitiveness in the liquid packaging industry, facilitating sustained business growth.

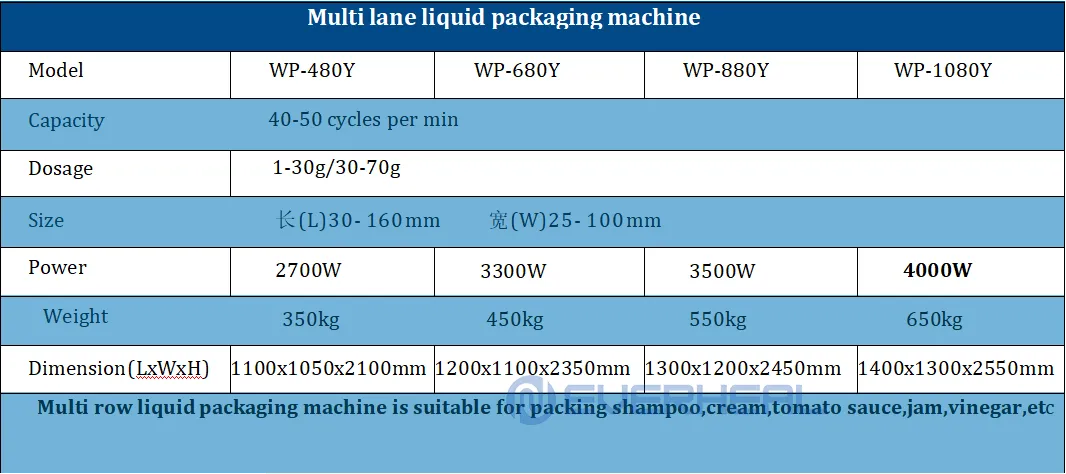

The Multi lane Liquid Packing Machine is an advanced and efficient packaging solution designed specifically for liquids such as water, juice, milk, oil, and other similar products. With its high-speed operation and precise filling mechanism, this machine is ideal for large-scale production facilities looking to enhance their packaging processes.

One of the key features of the Multi lane Liquid Packing Machine is its ability to operate on multiple lanes simultaneously. It is capable of handling up to ten lanes, allowing multiple products to be filled and packed simultaneously. This greatly increases the productivity and throughput of the packaging line, making it a preferred choice for businesses with high production demands.

The machine ensures accurate and consistent filling through its advanced filling system. It utilizes a volumetric filling mechanism that measures the liquid precisely before dispensing it into the pouch or container. This not only ensures the correct quantity of the product but also minimizes wastage, ultimately reducing production costs.

The Multi lane Liquid Packing Machine is designed to handle a wide range of pouch sizes and shapes. It can accommodate pouches ranging from 50 ml to 500 ml in capacity, making it versatile for various packaging requirements. With its adjustable pouch clamp, it securely holds the pouch in place during the filling process, preventing spillage or leakage.

Operating the machine is streamlined and straightforward. The user-friendly interface allows operators to easily control and monitor the machine's settings and performance. It features a touchscreen control panel with intuitive icons and displays, reducing the learning curve for operators and minimizing the risk of errors during operation.

The machine is equipped with high-quality sensors and detectors that ensure the integrity of the packaging process. It incorporates an automatic pouch detection system that identifies any irregularities or faults in the pouches, such as incorrect sealing or damaged pouches. This feature prevents faulty pouches from being filled and packed, ensuring that only high-quality, properly sealed products are delivered to customers.

The Multi lane Liquid Packing Machine is constructed with durable and hygienic materials, complying with industry standards for food safety and sanitation. Its stainless steel frame and components are resistant to rust and corrosion, ensuring a long lifespan and easy maintenance. The machine is designed for easy cleaning and sanitization, with removable parts and access points for thorough cleaning and preventive maintenance.

Furthermore, the Multi lane Liquid Packing Machine can be integrated into existing packaging lines seamlessly. It can be synchronized with upstream and downstream equipment such as conveyors, labeling machines, and end-of-line packaging systems, establishing a fully automated and efficient packaging process. This integration not only improves productivity but also reduces the need for manual labor and minimizes handling and transfer errors.

In conclusion, the Multi lane Liquid Packing Machine is a high-speed and versatile packaging solution designed for liquid products. With its ability to operate on multiple lanes and its precise filling mechanism, it enhances productivity and ensures accuracy in the packaging process. Its user-friendly interface, advanced sensors, and easy maintenance make it a reliable choice for businesses seeking to optimize their liquid packaging operations.

Hot Tags: Multi Lane Liquid Packing Machine, Liquid Packing Machine, Milk Packing Machine, Automatic Liquid Packaging Machine, Filling And Packaging, Coffee Packaging Machine, Oil Packing Machine, Pouch Packing Machine, Liquid Packaging, Pharmaceutical Liquid Packaging Machine, China, Customized, OEM, Low price, manufacturing company, manufacturers, factory, suppliers, quotation, for sale