|

Specifications and Technical Parameters

| Model |

Distilled Water Production (L/h) |

Steam Consumption (kg/h) |

Raw water consumption (kg/h) |

Dimensions (mm) |

| LD50-4 |

≥50 |

15 |

55 |

1200×720×1800 |

| LD100-4 |

≥100 |

30 |

110 |

1350×750×210 |

| LD200-4 |

≥200 |

60 |

220 |

1400×800×2300 |

| LD300-4 |

≥300 |

90 |

330 |

1500×960×2450 |

| LD500-5 |

≥500 |

120 |

550 |

2170×1160×2950 |

| LD750-5 |

≥750 |

180 |

825 |

2620×1250×3100 |

| LD1000-6 |

≥1000 |

200 |

1100 |

2420×1250×3300 |

| LD1500-6 |

≥1500 |

320 |

1650 |

3240×1380×3200 |

| LD2000-6 |

≥2000 |

400 |

2200 |

3240×1380×3400 |

| LD3000-5 |

≥3000 |

720 |

3300 |

3300×1500×3500 |

| LD3000-6 |

≥3000 |

600 |

3300 |

3760×1500×3500 |

| LD4000-6 |

≥4000 |

800 |

4400 |

4300×1650×3600 |

| LD5000-6 |

≥5000 |

1000 |

5500 |

4460×1700×3600 |

| LD6000-6 |

≥6000 |

1320 |

6600 |

4720×1800×3800 |

| LD7000-6 |

≥7000 |

1540 |

7700 |

5000×1800×4000 |

|

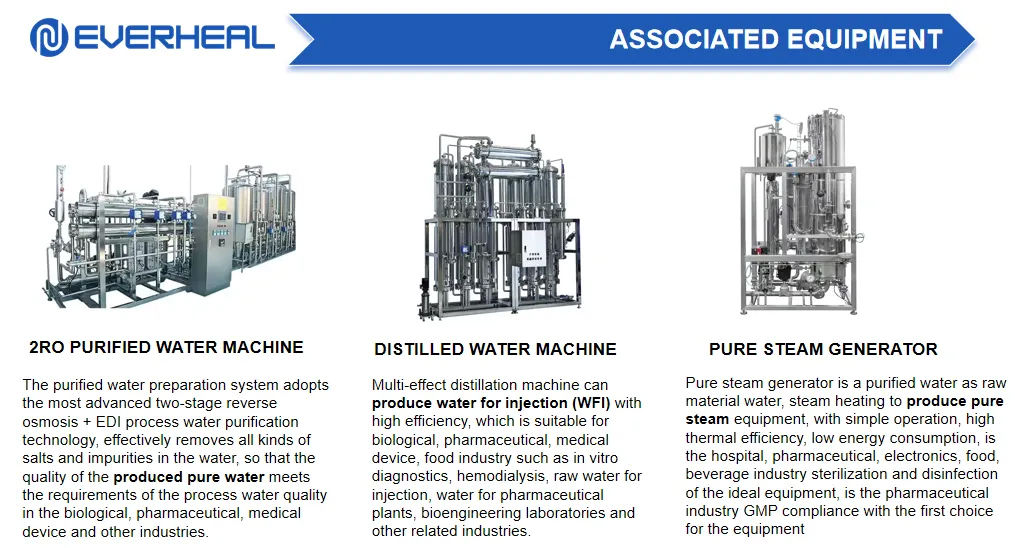

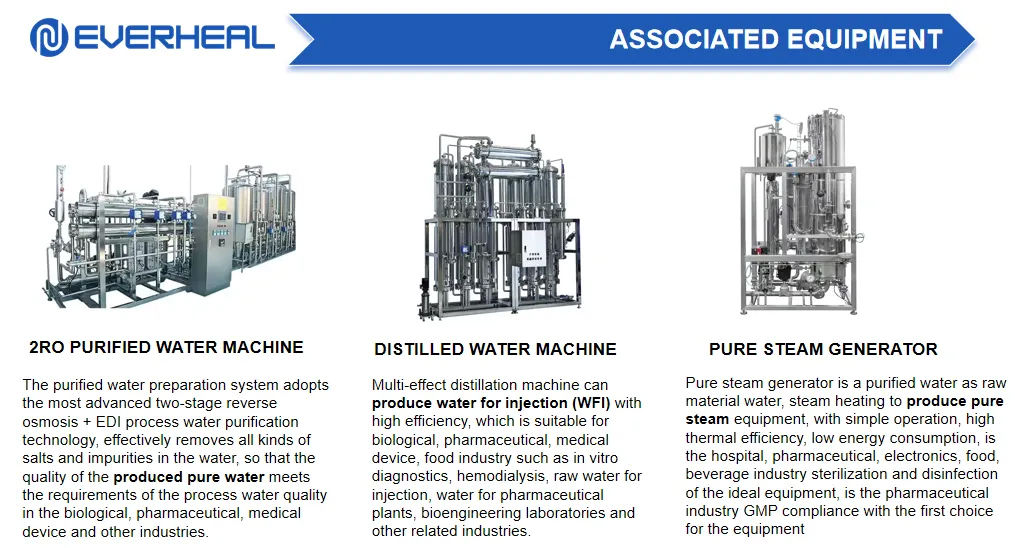

Key Functions and Introduction

In the pharmaceutical industry, the multi-function distillation water machine ensures the production of highly purified water, which is essential for the preparation of pharmaceutical ingredients and stringent quality control. Likewise, in the medical field, it plays a crucial role in supporting sterilization processes and maintaining hygiene standards. Laboratories extensively utilize this high-quality distilled water for research and experiments. Furthermore, it finds applications in the electronics manufacturing and chemical industries, where it is employed for tasks such as component cleaning and chemical reactions

Boiler: Responsible for heating water and generating steam.

Evaporator: Allows water to evaporate, separating it from impurities and contaminants.

Condenser: Cools the steam, causing it to condense into a liquid form.

Cooling System: Includes cooling coils or heat exchangers to reduce the temperature of distilled water after condensation.

Storage Tank: Collects and stores distilled water to ensure a continuous supply for various applications.

Control System: Comprising sensors, switches, and a control panel, it monitors and regulates the distillation process for optimal performance.

Safety Features: Equipped with safety functions, including pressure and temperature controls, as well as safety valves to prevent over pressure.

|

Usage Scope

Pharmaceutical Industry:

Primarily used for processes requiring high-purity water in pharmaceutical production, such as producing injection water, preparing drug solutions, cleaning equipment, and complying with GMP and FDA regulations.

Medical Facilities:

Suitable for sterilizing and disinfecting medical equipment in hospitals and healthcare facilities, as well as creating sterile environments in laboratories and operating rooms.

Laboratories:

Used in research and laboratory settings where high-purity water is required for experiments, including life sciences research, chemical experiments, and analytical testing.

Food and Beverage Industry:

Applied in the production process for tasks like cooking, cleaning, evaporation, and more, ensuring food quality and safety.

Electronics and Semiconductor Manufacturing:

Utilized for cleaning and etching electronic components, maintaining high cleanliness standards in the manufacturing process.

Chemical Industry:

Employed in chemical synthesis and experiments where high-purity water is needed, ensuring optimal reaction results and product quality.

|

Usage Guidelines

Regular Maintenance:

Perform regular cleaning and maintenance of the equipment to ensure stable performance and longevity.

Water Quality Monitoring:

Regularly monitor and test the water quality to ensure it meets the required standards and specifications.

Operator Training:

Ensure that equipment operators receive adequate training and understand the normal operation and maintenance procedures.

Protective Measures:

Use the necessary personal protective equipment, such as gloves and safety goggles, to ensure operator safety.

Cleaning Procedures:

Follow equipment cleaning procedures to ensure high purity and sterility of the steam. Pay attention to the cleaning frequency and methods.

Record Keeping:

Maintain detailed operational records, including maintenance and water quality monitoring records. Ensure proper document archiving and backup.

|

Why Choose Us

Pharmaceutical-Grade Purity:

Our Multi Function Distillation Water Machine is manufactured using pharmaceutical grade stainless steel and high efficiency purification processes, ensuring it delivers high purity and meets the hygiene and quality standards essential for pharmaceutical and medical facilities

Strict Manufacturing Processes and Quality Control:

We follow strict manufacturing processes and quality checks. Every generator undergoes thorough testing and inspection before it's shipped to ensure it provides a stable supply of steam during continuous operations. This reduces the risk of steam quality related issues in pharmaceutical production

Deployment of Experienced Engineers to Customer Facilities:

We dispatch experienced engineers to our customers' facilities. During the installation process, they supervise the equipment installation, ensuring that every component is correctly and accurately configured. Additionally, they provide detailed operating instructions to ensure customers can fully utilize the equipment's capabilities for efficient production.

Over 10 Years of Project Experience:

With over 10 years of successful project experience providing water purification solutions to the pharmaceutical industry,Our expertise and experience serve as strong support for the success of your projects.

|

Payment Terms

30% advance payment upon contract signing, with the remaining 70% to be settled before shipment.

Q: Where is your factory located?

A: Our factory is located in Ningbo, China, a port city along the East China Sea. This location ensures convenient shipping and rapid delivery worldwide.

Q: How many years of experience does your factory have?

A: Our factory has over 20 years of experience, focusing on manufacturing high-quality products and delivering solutions and services.

Q: How long is the delivery time for your products?

A: Our standard delivery time usually falls within the range of 60 to 90 days. We will provide the exact delivery time upon order confirmation. It depends on the specific product type, specifications, and order quantity.

Q: We have an overseas project. Do you have experience to provide support?

A: Yes, we have extensive overseas project experience. Please contact our sales team, and they will collaborate with you to provide engineering support and solutions, ensuring the successful implementation of your project.

Q: What after-sales service can you provide?

A: We will arrange engineers to video guide with you in the first time, if we can't solve the problem, we will arrange the service to customer site as soon as possible.

Hot Tags: Multi Function Distillation Water Machine, Industrial Distilled Water Machine, Distiller Machine, Distilled Water Maker Machine, Distilled Water Dispenser, Industrial Water Distillation Unit, Distilled Water Machine, Automatic Water Distillation Unit, Water Distillation Unit, Distilled Water Equipment, China, Customized, OEM, Low price, manufacturing company, manufacturers, factory, suppliers, quotation, for sal