Content Menu

● Understanding What a HEPA Air Filter Is

● How Do HEPA Air Filters Work?

>> Interception

>> Impaction

>> Diffusion

● Why 0.3 Microns Matter

● Key Applications of HEPA Air Filters

>> 1. Pharmaceutical and Biotechnology Facilities

>> 2. Hospitals and Healthcare Environments

>> 3. Industrial Production and Sensitive Manufacturing

>> 4. Home and Office Applications

● The Science of HEPA Filter Efficiency

● Comparing HEPA Filters with Other Purification Methods

● Advantages of HEPA Air Filters

● Limitations and Important Considerations

● Maintenance Best Practices

● Integration into Modern Pharmaceutical Equipment

● Energy Efficiency and Future Innovations

● Importance of HEPA Filtration in Sustainable Manufacturing

● Conclusion

● FAQ

>> 1. What makes a HEPA Air Filter different from regular filters?

>> 2. How often should I replace a HEPA filter?

>> 3. Can HEPA filters remove viruses?

>> 4. Are HEPA filters expensive to maintain?

>> 5. Do HEPA Air Filters create ozone?

Indoor air quality has become a serious environmental and public health issue worldwide. As global awareness increases about the dangers of pollutants, allergens, and airborne microorganisms, more people and industries are investing in advanced air purification systems. One of the most trusted and widely used technologies is the HEPA Air Filter. But many still ask — do HEPA filter air purifiers really work, and how do they perform in both home and industrial settings?

This article explores how HEPA filters function, their applications across various industries, their advantages and limitations, and why they remain the gold standard for air cleanliness — from households to pharmaceutical cleanrooms.

Understanding What a HEPA Air Filter Is

HEPA Air Filter stands for High-Efficiency Particulate Air filter. This technology was first created in the 1940s to trap radioactive dust during scientific research for the Manhattan Project. Since then, HEPA filters have evolved into an indispensable component of cleanroom environments, healthcare facilities, and even consumer appliances.

A true HEPA filter must eliminate 99.97% of particles measuring 0.3 microns. To give you perspective, a human hair is around 70 microns thick — over 200 times bigger than the particles a HEPA filter traps. This makes it powerful enough to capture pollen, pet dander, mold spores, certain bacteria, and even some viruses.

The HEPA Air Filter achieves this efficiency without relying on chemical treatments or electrostatic charge. Instead, it depends purely on mechanical filtration, ensuring a safe, consistent, and predictable performance for sensitive environments.

How Do HEPA Air Filters Work?

To understand why HEPA filters are so effective, we need to look at their internal structure and the science behind particulate capture.

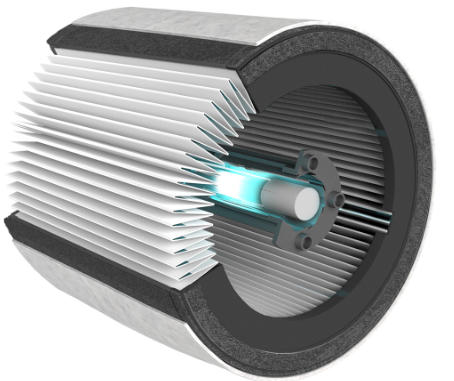

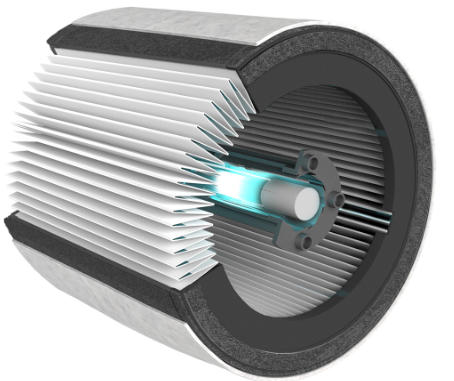

A HEPA Air Filter consists of a dense web of fine fibers—commonly made from fiberglass or synthetic materials—arranged in pleated layers. As air passes through, different sizes of particles are captured through several key mechanisms:

Interception

Larger airborne particles that follow the air stream come into contact with a fiber and get stuck when they come close enough.

Impaction

Medium-sized particles cannot easily change direction as air flows around fibers. They crash into the fibers and become trapped.

Diffusion

For ultrafine particles smaller than 0.1 microns, random motion (known as Brownian motion) causes them to collide with fibers, dramatically increasing the likelihood of being captured.

The combination of these mechanisms allows the HEPA Air Filter to handle a variety of particle sizes with exceptional accuracy. It is this intricate process that makes HEPA filters the benchmark for air purification systems.

Why 0.3 Microns Matter

You might wonder — why do standards focus on particles of 0.3 microns? That's because this size is known as the Most Penetrating Particle Size (MPPS). Particles larger than 0.3 microns tend to get trapped more easily through interception and impaction, while smaller particles (under 0.1 microns) are removed more through diffusion. Therefore, a filter rated for 0.3 microns effectively captures a wide range of both smaller and larger particles.

This balance ensures the HEPA Air Filter performs efficiently across different environments — from home air purifiers to critical pharmaceutical cleanrooms.

Key Applications of HEPA Air Filters

1. Pharmaceutical and Biotechnology Facilities

In pharmaceutical manufacturing, air purity is directly linked to product safety, potency, and sterility. Companies like Everheal, which specialize in pharmaceutical equipment such as pure water systems, clean steam generators, RO units, liquid filling and sealing machines, and sterilization systems, depend on HEPA filtration to maintain sterile and contamination-free conditions.

Cleanrooms used in the production of drugs, vaccines, and medical devices must meet specific ISO classifications (like ISO 5 or ISO 7). Here, the HEPA Air Filter integrates into air handling units (AHUs) to continuously purify recirculated air, preventing dust, microbes, or unwanted particles from compromising product integrity.

2. Hospitals and Healthcare Environments

HEPA filtration plays a pivotal role in infection control. In hospitals, surgical theaters, isolation wards, and laboratories, HEPA Air Filters remove airborne pathogens, minimizing the spread of infections such as tuberculosis, COVID-19, and other respiratory illnesses. Properly maintained systems can significantly reduce hospital-acquired infections (HAIs).

3. Industrial Production and Sensitive Manufacturing

Clean environments aren't limited to healthcare. Industries like electronics, optics, aerospace, and food packaging – all benefit from ultra-clean manufacturing zones. In electronics production, for example, dust particles can destroy semiconductor wafers. A robust HEPA Air Filter system protects products from microscopic defects, ensuring consistency and yield.

4. Home and Office Applications

At the consumer level, HEPA Air Filters have become common in air purifiers, HVAC systems, and vacuum cleaners. They're especially effective for allergy sufferers and individuals with asthma. A HEPA-equipped purifier can dramatically reduce pollen, dust, smoke, and even some airborne bacteria, providing fresher, cleaner indoor air.

The Science of HEPA Filter Efficiency

HEPA filters undergo rigorous laboratory testing to ensure they meet international standards. The primary metrics used include filtration efficiency, airflow resistance, and dust-holding capacity.

Testing protocols vary, but common standards include:

- EN 1822 (Europe): Defines particle retention levels using a most penetrating particle size test.

- MIL-STD-282 (U.S.): Military standard that measures particle capture efficiency.

- IEST-RP-CC001.6: Technical guide for cleanroom filter performance.

A true HEPA Air Filter certified under these standards must demonstrate a consistent 99.97% removal rate at 0.3 microns. However, in real-world scenarios, filters often exceed this level due to secondary diffusion effects, trapping particles even smaller than viruses.

Comparing HEPA Filters with Other Purification Methods

While HEPA filters offer excellent particulate filtration, they are just one of several technologies used in air purification systems. Each method targets specific contaminants:

| Technology | Function | Effectiveness | Drawbacks |

| HEPA Air Filter | Captures particulate matter | 99.97% at 0.3μm | Does not remove gases or odors |

| Activated Carbon Filter | Absorbs volatile organic compounds (VOCs) and smells | High for chemical vapors | Ineffective on physical particles |

| UV-C Sterilization | Kills microorganisms | Effective for bacteria/viruses | Needs proper exposure; may produce ozone |

| Ionization/Plasma Air Cleaners | Electrically charge and settle particles | Moderate | Can generate ozone; less predictable |

| Electrostatic Filters | Collect dust through electric field | Variable depending on humidity | Requires regular cleaning |

Thus, while UV or carbon filters complement air purification by addressing gases, odors, or pathogens, the HEPA Air Filter remains unmatched for removing particles — making it a foundational component in multiphase air systems.

Advantages of HEPA Air Filters

- Exceptional Filtration Efficiency: Removes nearly all fine particulates from the air, protecting occupants and equipment.

- Improved Respiratory Health: Reduces exposure to allergens, mold spores, and airborne bacteria.

- Low Maintenance: Typically only requires replacement once or twice a year.

- No Ozone or Chemical Emissions: Unlike ionizers, HEPA filters function purely mechanically.

- Applicable Across Environments: Performs well in homes, offices, healthcare, and industrial facilities.

- Supports Regulatory Compliance: Essential for GMP-certified pharmaceutical cleanrooms or FDA-inspected environments.

Limitations and Important Considerations

Despite its superior performance, the HEPA Air Filter does have limitations:

1. No Gas or Odor Removal: Gaseous pollutants, VOCs, and smoke odors require activated carbon filtration.

2. Airflow Restriction: Dense filters can lower airflow efficiency if not properly sized for the system.

3. Clogging Risks: Accumulated dust can raise energy consumption or reduce performance.

4. Replacement Cost: High-efficiency filters can be costly for large-scale systems.

5. Installation Quality Matters: Poor sealing allows air leakage, reducing efficiency dramatically.

When properly installed and maintained, however, these drawbacks are minimal compared to the health and safety benefits provided.

Maintenance Best Practices

Maintaining a HEPA Air Filter system correctly ensures optimal performance:

1. Regular Inspections: Visually inspect filters monthly for darkening, damage, or dust accumulation.

2. Scheduled Replacement: Follow manufacturer recommendations — usually between 6 to 12 months for home purifiers, or more frequently for high-demand industrial use.

3. Proper Sealing: Ensure filters are correctly embedded to prevent bypass leakage.

4. Integrity Testing: In pharmaceutical and cleanroom environments, conduct aerosol penetration tests (DOP/PAO tests) to verify filter integrity.

5. Environmental Monitoring: Ensure humidity and temperature remain within design parameters to avoid media deformation.

A well-maintained HEPA Air Filter system maintains efficiency, extends equipment life, and prevents contamination risks.

Integration into Modern Pharmaceutical Equipment

Modern pharmaceutical plant design integrates HEPA filtration within essential processing and packaging units. For example, Everheal's high-performance solutions incorporate HEPA Air Filter systems in:

- Sterilization Cabinets and Autoclaves to maintain clean airflow during sterilization processes.

- Liquid Filling and Sealing Machines where particle-free conditions prevent microbial contamination.

- Pure Steam and Water Systems ensuring sterile contact during fluid preparation processes.

- Controlled Air Handling Units (AHUs) delivering laminar clean airflow across manufacturing zones.

Integrating HEPA filters into these operations creates a robust and contamination-free workflow, aligning with GMP standards and international pharmaceutical compliance.

Energy Efficiency and Future Innovations

Traditional HEPA filters have faced criticism for high energy consumption due to airflow resistance. However, modern advancements have introduced low-pressure drop designs, nanofiber coatings, and composite layers that maintain high filtration efficiency while reducing energy load on fans and compressors.

The next generation of HEPA Air Filter technology focuses on:

- Eco-friendly materials: Recyclable and biodegradable fiber composites.

- Smart sensors: Monitoring filter saturation in real time.

- Antimicrobial coatings: Preventing bacterial growth on filter media.

- Hybrid filtration systems: Combining HEPA, carbon, and photocatalytic filters for comprehensive purification.

These innovations make HEPA filters more sustainable, cost-effective, and efficient — ideal for clean energy-driven industries and modern green buildings.

Importance of HEPA Filtration in Sustainable Manufacturing

The integration of HEPA Air Filter technology into industrial processes aligns with global sustainability goals. Clean manufacturing contributes not only to product quality but also to environmental safety. In pharmaceutical and biotechnology facilities, reduced particulate emissions mean cleaner exhaust air, leading to lower environmental impact and adherence to green factory standards.

Moreover, advanced energy-efficient HEPA systems help manufacturers achieve certifications like ISO 14001 for environmental management and LEED for green building design.

Conclusion

So, do HEPA filter air purifiers work? The evidence is overwhelmingly clear — HEPA Air Filters are among the most reliable and scientifically proven tools for improving air quality. They effectively capture nearly all airborne particles down to microscopic levels, make environments safer, and support precision manufacturing in critical industries such as pharmaceuticals and healthcare.

Although HEPA filters must be maintained properly and used alongside complementary technologies for odor and gas control, their advantages far outweigh their limitations. As the world continues to prioritize health, sustainability, and clean environments, the HEPA Air Filter will remain an essential technology for both industrial and everyday life.

FAQ

1. What makes a HEPA Air Filter different from regular filters?

A HEPA Air Filter meets a strict efficiency standard of capturing 99.97% of particles 0.3 microns in size, while ordinary filters capture far fewer particles and often allow fine allergens or microbes to pass through.

2. How often should I replace a HEPA filter?

Typically every 6–12 months, but in highly contaminated or high-usage environments, replacement may be required every 3–6 months. Always follow your manufacturer's maintenance schedule.

3. Can HEPA filters remove viruses?

Yes, to an extent. While viruses are smaller than 0.3 microns, many are carried by larger droplets or aerosols, which a HEPA Air Filter effectively captures through diffusion and interception.

4. Are HEPA filters expensive to maintain?

The cost depends on system size and use frequency. While initial costs can be higher than standard filters, the long-term health and operational benefits justify the investment, especially in critical environments.

5. Do HEPA Air Filters create ozone?

No. Unlike ionizers or certain UV systems, HEPA Air Filters operate mechanically and do not produce ozone or any harmful byproducts, making them safe for prolonged use in occupied spaces.