Content Menu

● What Is a Washable Air Filter?

>> How It Works

● Advantages of Washable Air Filters

>> 1. Cost Savings Over Time

>> 2. Eco-Friendly Solution

>> 3. Continuous Performance

>> 4. Durability and Strength

>> 5. Customizable for Specialized Applications

● Limitations of Washable Air Filters

>> 1. Limited Filtration Efficiency

>> 2. Regular Maintenance Is Essential

>> 3. Drying Time Before Reuse

>> 4. Initial Investment

● Where Are Washable Air Filters Used?

● Maintenance Tips for Washable Air Filters

● Comparing Washable vs. Disposable Air Filters

● Choosing the Right Washable Air Filter

● Is a Washable Air Filter Good for You?

● Conclusion

● FAQ About Washable Air Filters

>> 1. How often should I clean a washable air filter?

>> 2. Can I use soap or detergent when cleaning a washable air filter?

>> 3. Do washable air filters remove allergens and fine dust?

>> 4. How long can a washable air filter last?

>> 5. Are washable air filters suitable for pharmaceutical or cleanroom use?

In the modern era of environmental awareness and industrial precision, clean air is no longer a luxury but a necessity. Whether in residential HVAC systems, pharmaceutical cleanrooms, or industrial processing facilities, air filters play a crucial role in maintaining air quality. Among the different options available, the washable air filter has attracted attention for its eco-friendly features and long-term cost efficiency. But is a washable air filter really a good choice for your system? This article explores its performance, advantages, limitations, and proper maintenance to help you make an informed decision.

What Is a Washable Air Filter?

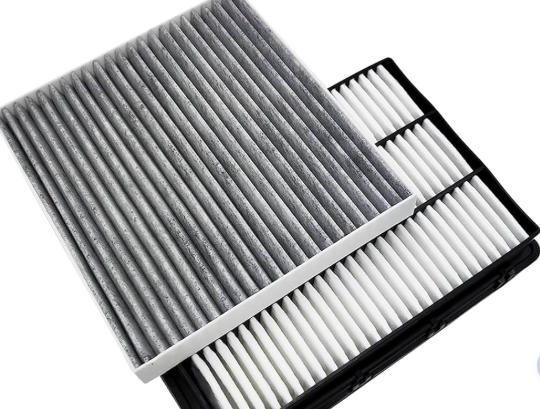

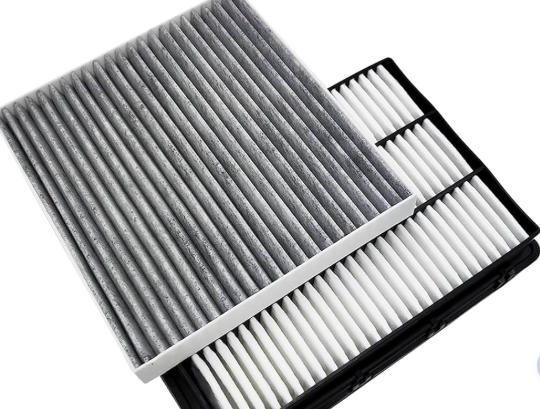

A washable air filter, sometimes called a reusable air filter, is designed to be cleaned and reused multiple times instead of being discarded after a single use. Unlike disposable filters made of paper or fiberglass, washable air filters use materials such as aluminum mesh, stainless steel, or synthetic fibers that can withstand washing and reinstallation.

How It Works

The structure of a washable air filter allows it to capture airborne contaminants like dust, pollen, smoke, and fine particles. As air passes through its multi-layer mesh surface, the particles adhere to the filter material. When airflow resistance increases—usually after several weeks of operation—the filter can be removed, washed with water or mild detergent, dried, and reinstalled.

Because of this reusability feature, washable air filters reduce waste and operating costs over the long term, making them popular in both commercial and industrial settings.

Advantages of Washable Air Filters

Washable air filters offer several practical and financial benefits. Here are the major ones:

1. Cost Savings Over Time

While the initial price of a washable air filter is higher than that of disposable ones, its lifetime cost is significantly lower. A single washable unit can last for several years, eliminating the recurring expense of monthly or quarterly replacements.

2. Eco-Friendly Solution

For industries committed to sustainability, washable air filters represent an excellent choice. By reducing waste and promoting material reuse, they align with green factory initiatives and global environmental standards such as ISO 14001.

3. Continuous Performance

With proper maintenance, reusable air filters can maintain stable filtering capacity throughout their lifespan. They can be cleaned whenever performance declines, restoring airflow and efficiency almost instantly. This makes them ideal for controlled environments—especially in pharmaceutical or food industries—where consistent air purity is mandatory.

4. Durability and Strength

Unlike fiberglass or cardboard filters that easily deform, washable air filters are built with metal frames and corrosion-resistant mesh layers. This makes them suitable for demanding industrial environments that require higher air pressure resistance and extended service life.

5. Customizable for Specialized Applications

Many manufacturers, including equipment providers in sectors like pharmaceuticals and electronics, offer tailored washable air filter solutions. These filters can be customized by size, layer thickness, filtration rating (MERV value), and resistance level according to specific process needs.

Limitations of Washable Air Filters

Even though washable filters have many advantages, they are not suitable for every application. It's important to understand their potential drawbacks before making a purchase decision.

1. Limited Filtration Efficiency

Standard washable air filters typically have lower MERV ratings (around 4 to 8), meaning they capture larger particles effectively but may not filter out fine contaminants such as bacteria or smoke particles. Therefore, they may not be ideal for ultra-clean facilities like pharmaceutical aseptic production rooms, where HEPA filtration is mandatory.

2. Regular Maintenance Is Essential

To maintain effectiveness, washable air filters must be cleaned frequently. Neglecting maintenance can lead to reduced airflow, higher energy consumption, and contamination risks. For industrial users, a fixed cleaning schedule or automated alert system is recommended.

3. Drying Time Before Reuse

After washing, the air filter must be completely dry before reinstallation. Moisture left inside the filter can promote microbial growth or cause corrosion. This downtime could interrupt certain continuous operation systems if spare filters are not available.

4. Initial Investment

The upfront cost of washable filters can be two to five times higher than disposable alternatives. Businesses must weigh this investment against their long-term maintenance budgets and sustainability goals.

Where Are Washable Air Filters Used?

Washable air filters are found in a wide range of industries because of their adaptability and long lifespan. Typical applications include:

- HVAC systems in offices, hospitals, and shopping centers.

- Pharmaceutical and biotechnology facilities that demand controlled clean air during process stages not requiring HEPA filtration.

- Food and beverage processing plants seeking hygienic yet cost-effective air management.

- Automotive manufacturing lines where dust control improves coating and assembly quality.

- Residential and commercial air purifiers for environmentally conscious homeowners.

The use of washable filters in pharmaceutical settings, for instance, provides both advantages and challenges. Companies such as Everheal, which specialize in pharmaceutical equipment—including purified water systems, pure steam generators, and sterilization solutions—often integrate washable filters in non-critical clean zones to support energy-efficient air management.

Maintenance Tips for Washable Air Filters

Proper cleaning ensures that washable air filters continue performing efficiently and hygienically throughout their lifetime. Below are industry-recommended best practices:

1. Check the filter regularly. Inspect airflow and pressure drops monthly to determine cleaning intervals.

2. Use gentle cleaning methods. Rinse with water or apply mild detergent for stubborn dust. Avoid high-pressure sprays or chemical solvents that can damage filter materials.

3. Dry completely before reuse. Allow at least 24 hours or use compressed air to accelerate drying.

4. Inspect for wear. Check mesh integrity, gasket seals, and frame alignment before reinstalling.

5. Maintain a backup filter. Having a spare ensures continuous operation during drying stages.

By adhering to these basic steps, users can extend the lifespan of washable filters up to 5–10 years, depending on environmental conditions.

Comparing Washable vs. Disposable Air Filters

| Feature | Washable Air Filter | Disposable Air Filter |

| Initial Cost | High | Low |

| Lifespan | 5–10 years | 1–3 months |

| Maintenance | Requires cleaning and drying | Simple replacement |

| Filtration Rating (MERV) | Typically 4–8 | 5–13 depending on type |

| Environmental Impact | Reusable, low waste | Generates waste |

| Ideal Use Case | Long-term, sustainable systems | Short-term, low-cost operations |

For businesses focused on energy efficiency and environmental performance, washable filters are usually a more strategic investment. However, disposable filters remain more suitable for critical clean environments where precise filtration grades (MERV 13–16 or HEPA) are required.

Choosing the Right Washable Air Filter

When selecting a washable air filter, consider these key parameters:

- MERV Rating: Identify the required filtration efficiency based on your facility's cleanliness standards.

- Material Type: Metal mesh is ideal for industrial strength, while synthetic fibers offer lightweight, economical options.

- Frame Design: Ensure it matches the existing system dimensions and sealing requirements.

- Operating Conditions: Temperature, humidity, and chemical exposure may influence filter performance.

- Regulatory Compliance: For pharmaceutical industries, ensure filters meet GMP and FDA guidelines for non-sterile zones.

Engaging with a certified equipment provider such as Everheal ensures proper system integration—whether for clean air delivery, filtration, or process safety.

Is a Washable Air Filter Good for You?

The answer depends on your operational goals and air quality requirements. A washable air filter provides durability, cost efficiency, and environmental benefits that appeal to most general HVAC users and non-critical industrial applications. However, it is less suited for ultra-clean environments with strict particulate control standards.

When paired with a strong cleaning and inspection protocol, washable air filters deliver outstanding long-term performance and a measurable reduction in waste generation.

Conclusion

A washable air filter is a smart and sustainable investment for industries and facilities seeking reduced operational costs and environmental footprint. Although not designed for the highest filtration ratings, its durability, reusability, and eco-friendly profile make it an ideal solution for most standard air circulation systems.

From commercial HVAC applications to pharmaceutical support equipment, washable air filters help maintain consistent airflow without constant replacements. Companies dedicated to clean production—like Everheal—can integrate them effectively into modern cleanroom and utility designs for sustainable growth.

FAQ About Washable Air Filters

1. How often should I clean a washable air filter?

Washable air filters should typically be cleaned every 30 to 60 days, depending on environmental dust concentration and system usage.

2. Can I use soap or detergent when cleaning a washable air filter?

Yes, mild detergent and lukewarm water can be used for thorough cleaning. Avoid harsh chemicals or solvents.

3. Do washable air filters remove allergens and fine dust?

Washable filters can capture larger particles such as dust and pollen but may not effectively remove microscopic allergens like smoke or bacteria unless treated with advanced coatings.

4. How long can a washable air filter last?

With proper maintenance, a washable air filter can last between 5 and 10 years before material fatigue reduces performance.

5. Are washable air filters suitable for pharmaceutical or cleanroom use?

Yes, but only in non-critical environments. For sterile or aseptic zones, HEPA or ULPA filters are still required to meet regulatory standards.