Content Menu

● Instability Challenges of Ascorbic Acid

● Role of Metal Ions in Ascorbic Acid Degradation

● Why Chelation Is Essential

● Mechanism: How EDTA Protects Ascorbic Acid

● Evidence from Formulation and Analytical Studies

● EDTA in Vitamin C Injections and Bulk Drug

● Synergy with Antioxidants, Buffers, and Other Excipients

● Process Integration in a Pharmaceutical Preparation System

>> Water and Utility Management

>> Contact Materials and Equipment

>> Dissolution, Mixing, and Deaeration

>> Filtration, Filling, and Sterilization

● Optimizing EDTA Level and pH

● Quality by Design (QbD) Perspective

● Applications Beyond Parenteral Products

● Safety and Regulatory Aspects of EDTA

● How Everheal Can Support EDTA‑Based Vitamin C Projects

● Conclusion

● FAQs

>> 1. How exactly does EDTA stabilize ascorbic acid?

>> 2. What EDTA concentration is typically used in vitamin C pharmaceutical preparations?

>> 3. Can EDTA completely prevent ascorbic acid degradation?

>> 4. Is the use of EDTA in parenteral vitamin C formulations considered safe?

>> 5. How should a Pharmaceutical Preparation System be designed for EDTA‑stabilized vitamin C products?

● Citations:

Ascorbic acid (vitamin C) is a highly effective antioxidant but is also chemically unstable, especially in aqueous solution. It degrades rapidly under the influence of oxygen, metal ions, light, and heat, which is a critical challenge for any modern Pharmaceutical Preparation System that handles vitamin C injections, syrups, or topical formulations. Ethylenediaminetetraacetic acid (EDTA) is a powerful chelating excipient used to improve the stability of ascorbic acid by binding trace metals and slowing oxidative degradation in pharmaceutical preparations.[6][8][9][10]

EDTA is now considered a key part of many formulation strategies where vitamin C is a primary active ingredient or a co‑antioxidant. When combined with proper pH control, oxygen management, and other antioxidants, EDTA enables Pharmaceutical Preparation Systems to produce more stable and reliable ascorbic acid products for global markets.[1][10][11]

Instability Challenges of Ascorbic Acid

Ascorbic acid is a water‑soluble vitamin that easily undergoes oxidation to dehydroascorbic acid and then to further degradation products. This oxidation process is accelerated by dissolved oxygen, transition metal ions like iron and copper, higher pH, elevated temperature, and exposure to light, all of which can appear at different stages in a Pharmaceutical Preparation System.[8][9][12]

Once oxidation starts, the active vitamin C content decreases, and the formulation may show yellowing or browning, turbidity, and off‑odor, which directly affects product quality and patient acceptance. In complex manufacturing lines, even very low levels of metal contamination from water systems, stainless‑steel equipment, or raw materials can significantly shorten the shelf life of vitamin C preparations.[9][12]

Role of Metal Ions in Ascorbic Acid Degradation

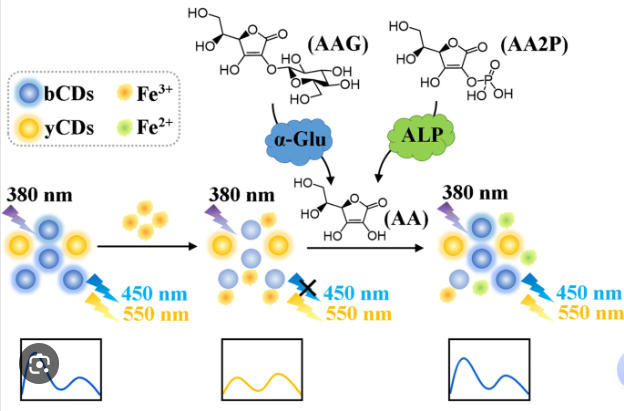

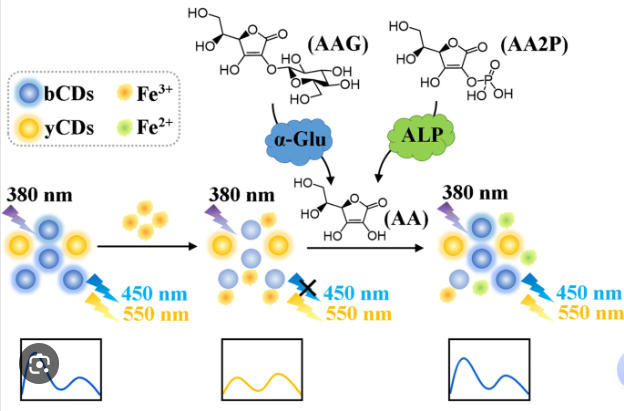

Transition metals such as Fe⊃3;⁺/Fe⊃2;⁺ and Cu⊃2;⁺ catalyze redox cycles that promote the formation of reactive oxygen species (ROS) in aqueous solutions containing ascorbic acid. These species trigger a chain reaction where vitamin C is oxidized rapidly, generating radicals and dehydroascorbic acid that further degrade into inactive compounds.[8][9]

This catalytic effect is especially problematic in large‑scale pharmaceutical preparation because metals may be introduced from multiple sources: purified water, process piping, valves, pump components, or even excipients. As a result, controlling metal‑catalyzed oxidation becomes a central design priority for any Pharmaceutical Preparation System that aims to maintain vitamin C potency during processing, filling, and storage.[13][9]

Why Chelation Is Essential

Chelation is the process by which a ligand binds to metal ions to form a stable complex, thereby reducing their free concentration and reactivity. In ascorbic acid formulations, chelating agents are used to bind trace metals and prevent them from participating in catalytic oxidation reactions that would otherwise degrade vitamin C.[6][9]

Among various chelating agents, EDTA is one of the most widely used in pharmaceuticals because it has high affinity for many divalent and trivalent metal ions (such as Ca⊃2;⁺, Mg⊃2;⁺, Fe⊃3;⁺, and Cu⊃2;⁺), good water solubility, and a strong safety record at low doses. Incorporating EDTA into a Pharmaceutical Preparation System helps ensure that any residual metals present in the process or ingredients are quickly complexed and rendered less reactive.[14][6]

Mechanism: How EDTA Protects Ascorbic Acid

EDTA acts mainly by forming strong complexes with metal ions that would otherwise catalyze oxidation reactions. When EDTA is added to an acidified ascorbic acid solution, it sequesters iron, copper, and other metals, thereby suppressing metal‑mediated redox cycles and limiting free radical formation.[6][8]

Classic studies show that small amounts of EDTA can completely protect ascorbic acid against copper‑catalyzed aerobic oxidation in acidified solutions for several days at room temperature. Under optimized conditions, solutions of ascorbic acid that contain EDTA can even withstand heating without significant vitamin loss, which is highly advantageous for certain Pharmaceutical Preparation System steps like thermal processing or controlled sterilization.[11][6]

Evidence from Formulation and Analytical Studies

Multiple studies and practical applications confirm EDTA's stabilizing role in vitamin C systems:

- In aqueous vitamin C syrups, combinations of disodium EDTA with antioxidants such as sodium metabisulfite significantly improved vitamin C stability, demonstrating that chelation plus radical scavenging provides synergistic protection.[10]

- In blood sample handling for ascorbic acid analysis, collecting blood into EDTA‑containing tubes and processing quickly led to minimal analyte loss, confirming that EDTA helps maintain vitamin C levels by preventing metal‑catalyzed degradation during storage and processing.[3][15]

- Patent literature for vitamin C injections describes formulations where EDTA is specifically included as a stabilizer, working together with sulfite or other antioxidants to maintain potency over the product's shelf life.[16][11]

These observations collectively support the use of EDTA as a critical stabilizer in Pharmaceutical Preparation Systems that manufacture and handle ascorbic acid‑containing pharmaceuticals.[11][16]

EDTA in Vitamin C Injections and Bulk Drug

EDTA is frequently used in vitamin C injection formulations and in the preparation of bulk vitamin C drug substance. It may be introduced during dissolution, purification, or final formulation, depending on the process design and stability requirements of the Pharmaceutical Preparation System.[16][11]

Some bulk vitamin C manufacturing processes specify EDTA at approximately 0.5–1‰ (0.05–0.1%) of the vitamin C mass during dissolution and refining steps, helping to protect the vitamin against oxidation during crystallization and drying. In certain vitamin C injections, disodium EDTA is used alongside sulfites or cysteine as part of a stabilizer system in concentrated ascorbic acid solutions intended for parenteral use.[17][11][16]

Synergy with Antioxidants, Buffers, and Other Excipients

While EDTA is powerful on its own, it works best as part of a multi‑component stabilization strategy.[1][10]

- Sodium metabisulfite, sodium sulfite, and other reducing agents can directly scavenge oxygen and radicals, while EDTA prevents metal‑driven radical generation; together they slow both initiation and propagation of oxidative pathways.[10][11]

- Buffers such as sodium bicarbonate or other pH‑adjusting agents are used to keep the solution in a range where ascorbic acid is more stable and EDTA remains active as a chelator.[1][11]

Designing this excipient matrix is a core task in formulation development and must be closely aligned with the design and control strategy of the Pharmaceutical Preparation System.[1]

Process Integration in a Pharmaceutical Preparation System

To fully exploit EDTA's stabilizing effect, its use must be integrated throughout the process flow of a Pharmaceutical Preparation System:

Water and Utility Management

High‑purity water and pure steam are the foundation for stable vitamin C formulations. Systems that include multi‑stage treatment, deionization, and continuous monitoring help keep metals at very low levels before EDTA is ever added to the product.[13]

A well‑designed Pharmaceutical Preparation System ensures that water storage, distribution loops, and points of use are built from appropriate materials and maintained to minimize corrosion and metal leaching. This reduces the burden on EDTA and contributes to long‑term stability.[13]

Contact Materials and Equipment

Process equipment such as tanks, piping, valves, and heat exchangers are usually made of stainless steel, which can release trace metals under aggressive conditions. Surface finish, passivation treatments, and correct material grades are therefore selected carefully, particularly in acidic vitamin C processes.[9]

By combining optimized equipment materials with EDTA in the formulation, manufacturers create a dual barrier against metal‑catalyzed oxidation inside the Pharmaceutical Preparation System.[9][6]

Dissolution, Mixing, and Deaeration

In many processes, ascorbic acid is first dissolved in purified water, then buffer components and other excipients (including EDTA) are added under controlled agitation. The sequence and conditions affect how effectively EDTA can complex any metals present, so process parameters such as mixing time, shear, and temperature are carefully optimized.[16][1]

Deaeration methods, such as nitrogen sparging or vacuum, can be used to reduce dissolved oxygen at critical points, further lowering oxidation risk even after EDTA has bound the metals. This combination enables a more robust Pharmaceutical Preparation System for sensitive ascorbic acid formulations.[11][1]

Filtration, Filling, and Sterilization

After mixing, solutions often undergo clarification or sterilizing filtration before being filled into final containers. The filter materials are selected to avoid introducing additional metal contaminants or interacting unfavorably with EDTA or ascorbic acid.[13]

For injection products, terminal sterilization or aseptic processing must be validated so that temperature and holding times do not cause excessive vitamin C degradation. EDTA's ability to protect ascorbic acid at elevated temperatures under certain conditions is particularly valuable during these steps in the Pharmaceutical Preparation System.[6][11]

Optimizing EDTA Level and pH

The effectiveness of EDTA depends heavily on its concentration and the pH of the system.[10][6]

Formulation studies in vitamin C syrups have identified relatively low EDTA concentrations (such as around 0.0025% w/v) as optimal, especially when combined with sodium metabisulfite, whereas excessive EDTA may not provide additional benefit and can even show pro‑oxidant behavior outside the optimal pH range. Likewise, bulk vitamin C production patents suggest narrow EDTA ranges (0.5–1‰ of vitamin mass) that balance chelation efficiency and regulatory requirements.[10][16][6]

In development, design‑of‑experiments (DoE) methodologies are often used to model the influence of EDTA level, buffer concentration, antioxidant type, and temperature on ascorbic acid stability. These experiments define a robust design space that can be implemented and controlled within the Pharmaceutical Preparation System.[1]

Quality by Design (QbD) Perspective

Applying Quality by Design principles to vitamin C formulations with EDTA leads to better understanding and more reliable performance.[1]

Researchers have used factorial experimental designs to test combinations of EDTA, sodium metabisulfite, other chelators, and preservatives, then measured ascorbic acid content over time under different storage conditions. The results enable mathematical modeling of stability, prediction of product behavior, and optimization of excipient levels while minimizing overall excipient burden.[10][1]

Such QbD approaches support scale‑up and technology transfer of Pharmaceutical Preparation Systems by defining critical material attributes (like EDTA purity and concentration) and critical process parameters (such as pH, mixing speed, and storage temperature) that must be controlled to maintain stability.[1]

Applications Beyond Parenteral Products

The stabilizing concept of EDTA–ascorbic acid is relevant not only to injections but also to multiple dosage forms and industries.

- In oral liquids and syrups, EDTA helps maintain vitamin C content by reducing metal‑promoted oxidation, often in combination with sweeteners, flavors, and colorants that may carry trace metals.[10]

- In cosmetics and topical products, EDTA is widely used as a chelator in vitamin C formulations to limit discoloration and loss of activity during storage, alongside strategies such as encapsulation and low‑pH systems.[12]

- Insights from other EDTA‑stabilized systems, such as nanostructured lipid carriers where EDTA improved stability of other oxidizable actives, further support the use of chelators in complex formulations.[5]

All of these applications benefit from Pharmaceutical Preparation Systems that can precisely control raw‑material quality, dosage of EDTA, and process conditions.

Safety and Regulatory Aspects of EDTA

EDTA (including disodium edetate) is recognized as a pharmaceutical excipient in major pharmacopoeias and has a long history of safe use at low concentrations. Its total exposure in a finished product must be evaluated according to route of administration, expected daily dose, and patient population, especially for parenteral products.[14][17]

Regulators expect manufacturers to justify the use and level of EDTA through toxicological data, formulation rationale, and stability studies. The Pharmaceutical Preparation System must also comply with Good Manufacturing Practice (GMP), including validated cleaning procedures to prevent unintended EDTA carryover into products that do not require chelation. Continuous stability monitoring then confirms that EDTA is performing as intended over the product's shelf life.[17][14][13][1]

How Everheal Can Support EDTA‑Based Vitamin C Projects

Everheal, as a specialized Chinese manufacturer of pharmaceutical equipment and turnkey lines, can provide integrated solutions for vitamin C and other oxidation‑sensitive products:

- Designing custom dissolution, mixing, and dosing modules that allow precise introduction of EDTA and other stabilizers into ascorbic acid solutions.

- Engineering purified water and pure steam systems with extremely low metal content, reducing oxidation pressure even before chelators are used.[13]

- Implementing automated, PLC‑controlled Pharmaceutical Preparation Systems that maintain critical parameters (pH, temperature, dissolved oxygen, and mixing conditions) within validated ranges derived from QbD studies.[1]

This integrated approach helps global pharmaceutical customers obtain stable, high‑quality vitamin C formulations that meet regulatory and commercial expectations.

Conclusion

EDTA plays a central role in improving the stability of ascorbic acid in pharmaceutical preparations by chelating trace metal ions that catalyze oxidative degradation. When combined with appropriate antioxidants, buffers, and carefully controlled processing conditions, EDTA significantly extends the shelf life and quality of vitamin C injections, syrups, and topical products produced in a modern Pharmaceutical Preparation System. Through thoughtful formulation design, QbD‑based optimization, and robust equipment engineering, manufacturers can fully exploit EDTA's protective capabilities to deliver reliable vitamin C medicines to patients worldwide.[8][11][16][6][10][1]

FAQs

1. How exactly does EDTA stabilize ascorbic acid?

EDTA stabilizes ascorbic acid by forming strong complexes with catalytic metal ions like iron and copper, which would otherwise accelerate oxidation in aqueous solution. By reducing the concentration of free metals, EDTA suppresses radical formation and slows the conversion of vitamin C into dehydroascorbic acid and further degradation products.[8][9][6]

2. What EDTA concentration is typically used in vitamin C pharmaceutical preparations?

Formulation studies in vitamin C syrups have identified low concentrations of EDTA (around 0.0025% w/v) as particularly effective when used together with sodium metabisulfite. Certain bulk vitamin C processes use EDTA at about 0.5–1‰ of the vitamin mass, but the exact concentration must be optimized case‑by‑case within each Pharmaceutical Preparation System according to stability data and regulatory limits.[16][10][1]

3. Can EDTA completely prevent ascorbic acid degradation?

EDTA can strongly reduce metal‑catalyzed oxidation but cannot fully eliminate all degradation pathways such as non‑metal‑mediated oxidation, hydrolysis, or degradation due to heat and light. Therefore, EDTA must be combined with appropriate pH control, oxygen reduction, temperature and light management, and additional antioxidants within a robust Pharmaceutical Preparation System.[12][11][8][1]

4. Is the use of EDTA in parenteral vitamin C formulations considered safe?

Disodium EDTA has been used safely at low levels in parenteral formulations, including some ascorbic acid injections, as long as total daily exposure is kept within accepted toxicological limits. Regulatory authorities require justification of EDTA content through safety data, formulation rationale, and stability results, which together define acceptable use conditions in the final product.[14][17][11]

5. How should a Pharmaceutical Preparation System be designed for EDTA‑stabilized vitamin C products?

A suitable system should include high‑purity water and pure steam generation with low metal content, corrosion‑resistant contact materials, controlled EDTA solution preparation and dosing, efficient mixing, and validated filtration and sterilization steps. Automated monitoring of pH, temperature, dissolved oxygen, and chelator concentration, combined with QbD‑based process control, ensures that EDTA consistently provides optimal stabilization of ascorbic acid during manufacturing and storage.[11][16][13][1]

Citations:

[1](https://pmc.ncbi.nlm.nih.gov/articles/PMC7704847/)

[2](https://www.ijpsonline.com/articles/optimization-of-disodium-edetate-and-few-potent-antioxidants-requirement-for-the-stabilization-of-vitamin-c-in-solution.pdf)

[3](https://pubmed.ncbi.nlm.nih.gov/12227861/)

[4](https://www.sciencedirect.com/science/article/am/pii/S0378517320310772)

[5](https://onlinelibrary.wiley.com/doi/abs/10.1002/ejlt.201300509)

[6](https://www.semanticscholar.org/paper/Inhibition-of-oxidation-of-ascorbic-acid-by-EDTA-Rao-Sastry/2954800cf260d34ee00dac8dbee3aab2dfb6173f)

[7](https://pubs.acs.org/doi/full/10.1021/acsanm.5c02114)

[8](https://www.nature.com/articles/s41598-021-86477-8)

[9](https://pmc.ncbi.nlm.nih.gov/articles/PMC7460366/)

[10](https://www.sciencepub.net/researcher/research0610/002_26914research061014_6_9.pdf)

[11](https://patents.google.com/patent/CN102247317A/en)

[12](https://rjtcsonline.com/HTML_Papers/Research%20Journal%20of%20Topical%20and%20Cosmetic%20Sciences__PID__2022-13-1-2.html)

[13](https://lupinepublishers.com/surgery-case-studies-journal/pdf/SCSOAJ.MS.ID.000114.pdf)

[14](https://pubmed.ncbi.nlm.nih.gov/6436321/)

[15](https://www.sciencedirect.com/science/article/abs/pii/S0009898101005770)

[16](https://patents.google.com/patent/CN102558114B/en)

[17](https://pharmacyce.unm.edu/nuclear_program/neolibrary/libraryfiles/package_inserts/mallinckrodt_ascorbic_acid.pdf)