Content Menu

● Understanding the HEPA Air Filter

>> What Does “HEPA” Mean?

>> How Does a HEPA Filter Work?

● The Anatomy of a HEPA Air Filter

● Role of HEPA Air Filters in Air Purifiers

>> Ensuring Clean Indoor Air Quality

>> Pharmaceutical and Industrial Applications

● Benefits of Using HEPA Air Filters

>> 1. Superior Airborne Particle Removal

>> 2. Enhanced Worker Health and Safety

>> 3. Regulatory Compliance

>> 4. Long-Term Cost Efficiency

● Types of HEPA Air Filters

● Installation and Maintenance Best Practices

● HEPA Air Filters in Cleanroom Design

● HEPA vs. Other Filter Types

>> HEPA vs. Activated Carbon Filters

>> HEPA vs. ULPA Filters

>> HEPA vs. Electrostatic Filters

● Environmental Considerations of HEPA Filters

● How HEPA Air Filters Support Pharmaceutical Manufacturing Standards

● Conclusion

● FAQs About HEPA Air Filters

>> 1. What particle size can HEPA filters capture?

>> 2. How often should a HEPA Air Filter be replaced?

>> 3. Are HEPA Air Filters washable?

>> 4. What is the difference between HEPA and ULPA filters?

>> 5. Why are HEPA Air Filters essential in pharmaceutical manufacturing?

In the field of pharmaceutical manufacturing, laboratory environments, and cleanroom engineering, maintaining air purity is not just a matter of comfort—it's a technical necessity. Among the many innovations designed to ensure a contaminant-free environment, the HEPA Air Filter stands as one of the most effective solutions for capturing microscopic airborne particles.

This article explores in depth what a HEPA filter is, how it works, why it's vital for air purifiers, and how industries like pharmaceuticals and biotechnology rely on it to achieve high-level cleanliness and compliance standards.

Understanding the HEPA Air Filter

What Does “HEPA” Mean?

HEPA stands for High-Efficiency Particulate Air, a globally recognized standard for filtration performance. To qualify as a HEPA Air Filter, a product must be capable of removing at least 99.97% of airborne particles as small as 0.3 microns in diameter, which include bacteria, dust, smoke, allergens, and aerosolized droplets.

The standard was originally developed during World War II to prevent the spread of radioactive contaminants, but now it has applications across industries—from air purifiers and HVAC systems to pharmaceutical cleanrooms and medical laboratories.

How Does a HEPA Filter Work?

Unlike a simple mesh or screen, a HEPA Air Filter uses a complex network of fine fibers—usually made from fiberglass or synthetic materials—that trap airborne contaminants through three main mechanisms:

1. Interception: Particles moving in the airstream adhere to fibers when passing close to them.

2. Impaction: Larger particles cannot change their path as easily and collide directly with fibers.

3. Diffusion: Smaller particles, under one micron, move erratically (Brownian motion) and are captured more easily.

Together, these mechanisms make HEPA filters uniquely effective across a wide range of particle sizes, which is why they remain the benchmark in air purification systems.

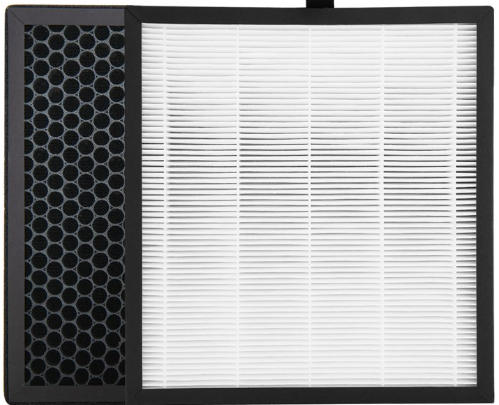

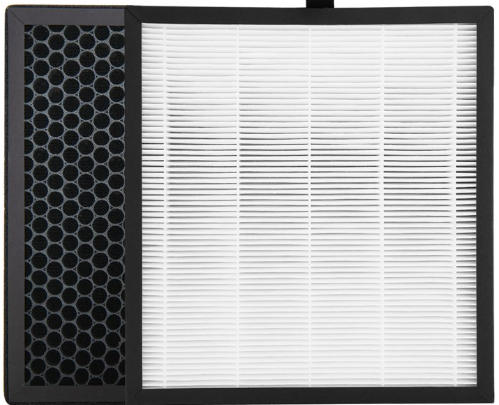

The Anatomy of a HEPA Air Filter

A standard HEPA Air Filter consists of multiple layers:

- Outer Pre-Filter: Captures larger particles such as dust and hair, extending HEPA filter life.

- HEPA Media Layer: The main filtration structure trapping microscopic particles.

- Supporting Mesh or Frame: Provides mechanical stability and prevents collapse under airflow.

- Sealing Components: Prevent leaks along edges that could compromise air quality.

In pharmaceutical production and biotechnological environments, filters are often designed with sterile-grade seals and stainless-steel housings to meet stringent hygiene requirements.

Role of HEPA Air Filters in Air Purifiers

Ensuring Clean Indoor Air Quality

For residential and commercial use, air purifiers equipped with HEPA filters are designed to remove airborne pollutants like mold spores, pollen, and smoke. But in industrial and laboratory applications, HEPA filters go a step further—they maintain sterile conditions essential for the production of drugs, vaccines, and medical devices.

Pharmaceutical and Industrial Applications

In pharmaceutical plants, HEPA Air Filters are installed in cleanroom HVAC systems, ensuring that airborne contaminants do not interfere with the manufacturing of sterile products. This includes areas related to:

- Formulation and Mixing Rooms

- Filling and Sealing Machines

- Sterilization and Packaging Zones

Companies like Everheal, a Chinese pharmaceutical equipment manufacturer, integrate HEPA filtration into clean environments across their systems—such as water purification units, distillation apparatus, and sterilization equipment—to maintain GMP-compliant production standards.

Benefits of Using HEPA Air Filters

1. Superior Airborne Particle Removal

HEPA filters capture fine contaminants better than standard filters. They efficiently trap bacteria, viruses, and dust, maintaining product integrity in pharmaceutical manufacturing.

2. Enhanced Worker Health and Safety

By filtering out airborne allergens and harmful contaminants, HEPA filtration helps protect worker respiratory health in laboratory and cleanroom environments.

3. Regulatory Compliance

Pharmaceutical regulations such as ISO 14644 and GMP guidelines require the use of HEPA-filtered air within critical production areas. Compliance ensures product quality and regulatory approval.

4. Long-Term Cost Efficiency

Although HEPA filters can be more expensive initially, their longer service life, reduced maintenance frequency, and prevention of contamination events make them economically beneficial.

Types of HEPA Air Filters

There are several classifications of HEPA Air Filters, depending on their efficiency and industrial use:

| Filter Type | Efficiency Rating | Common Applications |

| E10–E12 (EPA) | 85–99.5% | Air conditioning and household air purifiers |

| H13–H14 (HEPA) | 99.95–99.995% | Pharmaceutical cleanrooms, operating theaters |

| U15–U17 (ULPA) | 99.9995–99.999995% | Semiconductor, nanotechnology, biosafety labs |

For pharmaceutical manufacturing plants, H13 and H14 grades are most commonly used to maintain strict sterile conditions.

Installation and Maintenance Best Practices

Proper installation and regular replacement or cleaning are key to maintaining HEPA efficiency. Here are essential practices:

1. Proper Sealing: Ensure airtight installation using gasket or gel-seal frames to prevent bypass leakage.

2. Pre-Filter Use: Always install a pre-filter to capture large dust particles and prolong HEPA filter life.

3. Regular Integrity Testing: Conduct DOP/PAO testing to confirm there are no leaks through or around filters.

4. Scheduled Replacement: Typically every 6–12 months in high-demand environments.

5. Controlled Handling: Filters should be changed under clean conditions to avoid reintroducing contaminants.

HEPA Air Filters in Cleanroom Design

Cleanrooms rely on HEPA Air Filters as the backbone of air circulation systems. They are usually installed either in ceiling modules or terminal diffusers positioned above critical zones. Combined with laminar airflow systems, HEPA filters create a continuous flow of sterile air, sweeping contaminants away from production zones.

At Everheal, cleanroom projects typically integrate HEPA filtration with advanced monitoring instruments to maintain consistent pressure differentials, humidity, and airflow velocity according to GMP layout standards.

HEPA vs. Other Filter Types

HEPA vs. Activated Carbon Filters

While HEPA filters remove physical particles, activated carbon filters focus on absorbing gases, odors, and volatile organic compounds. Many high-grade air purifiers combine both for complete purification.

HEPA vs. ULPA Filters

ULPA (Ultra-Low Penetration Air) filters exceed HEPA in filtration efficiency but come with higher pressure drops and energy costs. In pharmaceutical systems where ultra-sterile conditions are mandatory, ULPA may be used in Class 100 or ISO 5 environments.

HEPA vs. Electrostatic Filters

Electrostatic filters capture charged particles but are less reliable for fine particulate removal. HEPA filters remain more predictable and consistent for critical applications.

Environmental Considerations of HEPA Filters

Although HEPA filters are not reusable due to their fine fiber structure, some modern designs are recyclable or come with biodegradable materials. Manufacturers are now moving toward sustainable HEPA technologies with lower pressure drops and longer operational life.

Recycling programs help minimize environmental impact from disposed filters, especially in large pharmaceutical and healthcare facilities that frequently replace filters.

How HEPA Air Filters Support Pharmaceutical Manufacturing Standards

In Good Manufacturing Practice (GMP) facilities, air cleanliness directly impacts product safety. Contaminants can cause sterility failures, product recalls, or even regulatory shutdowns. For this reason, HEPA filters are integrated into:

- Cleanroom ceilings and air handling units (AHU)

- Isolators and filling machines

- Autoclave and sterilization chambers

- Laminar flow hoods for aseptic operations

By filtering air in these critical environments, HEPA systems ensure contaminant-free pharmaceutical production and protect end-user health.

Conclusion

The HEPA Air Filter remains a cornerstone technology in ensuring air purity and safety across residential, commercial, and industrial environments. For companies like Everheal, which provide full-spectrum pharmaceutical manufacturing equipment and cleanroom solutions, integrating HEPA filters is an indispensable part of achieving international GMP and ISO compliance.

Beyond just particle removal, HEPA filtration ensures process integrity, product consistency, and long-term operational efficiency—making it an essential investment for any operation requiring pure, contaminant-free air.

FAQs About HEPA Air Filters

1. What particle size can HEPA filters capture?

HEPA filters capture 99.97% of airborne particles as small as 0.3 microns, including bacteria, dust, and viral aerosols.

2. How often should a HEPA Air Filter be replaced?

In industrial settings, replacement should occur every 6–12 months depending on air quality and operational intensity. Regular integrity tests can extend service life safely.

3. Are HEPA Air Filters washable?

Most true HEPA filters are not washable because moisture can damage fibers and reduce efficiency. Only specific washable models are designed for that purpose.

4. What is the difference between HEPA and ULPA filters?

ULPA filters have higher efficiency (up to 99.999995%) than HEPA filters but also greater airflow resistance and higher energy requirements.

5. Why are HEPA Air Filters essential in pharmaceutical manufacturing?

Because they ensure aseptic conditions by removing airborne contaminants that could compromise drug safety and compliance with GMP standards.