Content Menu

● Understanding the HEPA Air Filter

>> The Structure of HEPA Filters

● The Working Principle of HEPA Air Purifiers

>> Stages in HEPA Purification Process

● Importance of HEPA Air Filters in Pharmaceutical and Industrial Settings

>> Cleanroom Applications

>> Regulatory Compliance

● Types of HEPA Air Filters

>> 1. True HEPA Filters

>> 2. HEPA-Type Filters

>> 3. ULPA Filters

● Benefits of Using HEPA Air Purifiers

>> 1. Superior Air Quality

>> 2. Allergens and Pathogen Control

>> 3. Longevity of Equipment

>> 4. Energy Efficiency with Proper Design

>> 5. Regulatory and Export Advantages

● Maintenance and Replacement of HEPA Air Filters

>> Maintenance Best Practices

● Choosing the Right HEPA Air Purifier

>> Key Considerations

● HEPA Air Filter Technology and Global Sustainability

● Conclusion

● FAQs About HEPA Air Filters

>> 1. What is the Difference Between HEPA and ULPA Filters?

>> 2. How Long Do HEPA Filters Last?

>> 3. Can HEPA Air Filters Remove Viruses?

>> 4. Are HEPA Air Purifiers Suitable for Large Facilities?

>> 5. How Often Should HEPA Filters Be Tested?

Air purification has become essential in modern manufacturing, healthcare, and pharmaceutical environments where air quality directly influences product safety and human health. Among the various purification technologies, the HEPA Air Filter stands as the gold standard for removing microscopic contaminants from the air. For companies like Everheal, which specialize in high-demand industries such as pharmaceuticals, sterile packaging, and cleanroom systems, HEPA technology is not just a benefit—it's a necessity.

This article explores what HEPA Air Filters are, how they work, their benefits, applications, and maintenance requirements. It also examines their critical role in controlled environments and industrial processes where air purity is fundamental.

Understanding the HEPA Air Filter

A HEPA (High-Efficiency Particulate Air) filter is a mechanical filtration device designed to trap at least 99.97% of airborne particles as small as 0.3 micrometers. That includes tiny particles such as dust, pollen, mold spores, bacteria, and even certain viruses. The HEPA Air Filter is built to achieve exceptionally high levels of purification, far beyond what conventional filters can provide.

The Structure of HEPA Filters

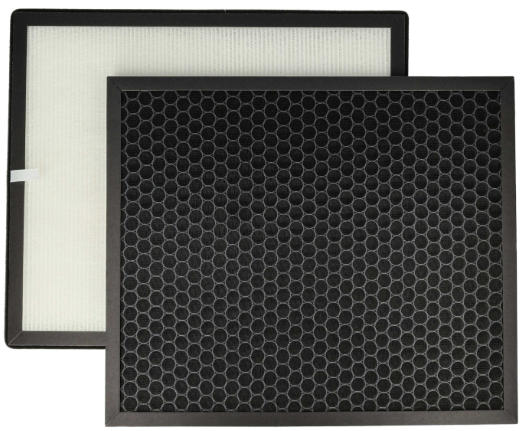

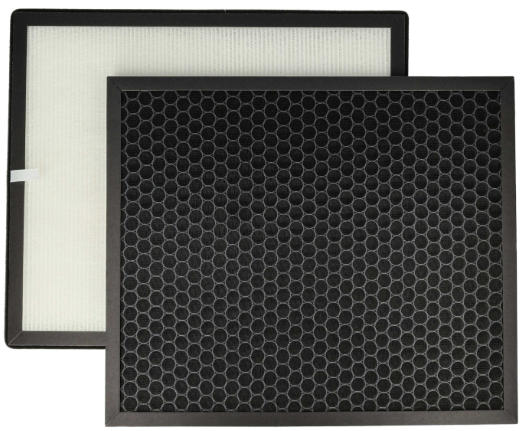

A HEPA Air Filter typically consists of multiple layers of fine mesh fibers—usually made from fiberglass or synthetic polymers—arranged in a dense, pleated pattern. This pleated design increases the surface area, allowing the filter to capture more pollutants while maintaining consistent airflow.

The fibers act as a maze for air contaminants. Particles are captured through several mechanisms:

- Interception: Medium-sized particles follow the air streamlines and stick to fiber surfaces.

- Impaction: Larger particles are unable to avoid the fibers and collide directly.

- Diffusion: Very small particles move erratically and are easily trapped by fibers.

The combination of these three mechanisms allows the HEPA Air Filter to achieve ultra-high filtration efficiency.

The Working Principle of HEPA Air Purifiers

A HEPA Air Purifier is an integrated system that combines a fan, an air pathway, and a HEPA Air Filter unit. The device draws in contaminated air, passes it through pre-filters to capture larger dust and debris, and then forces it through the HEPA filter media. Clean air is released on the other side.

Some advanced systems, particularly those used in laboratories, pharmaceutical manufacturing facilities, or hospital cleanrooms, pair HEPA filters with activated carbon filters to remove gaseous pollutants, odors, and volatile organic compounds (VOCs).

Stages in HEPA Purification Process

1. Pre-Filter Stage: Captures larger particles like dust and hair to extend HEPA filter life.

2. HEPA Filtration Stage: Removes fine particles and microorganisms.

3. Optional Activated Carbon Stage: Eliminates gases, odors, and chemical fumes.

4. Air Output Stage: Clean air is recirculated into the environment, maintaining high-quality standards.

This multi-layered system ensures deep filtration with minimal resistance, optimizing indoor or process air quality.

Importance of HEPA Air Filters in Pharmaceutical and Industrial Settings

For a company like Everheal, specializing in pharmaceutical equipment such as pure water systems, distilled water machines, and sterilization systems, maintaining controlled air environments is crucial. Contaminated air can compromise product purity, reduce yield, and violate regulatory standards.

Cleanroom Applications

In pharmaceutical manufacturing, HEPA Air Filters form a critical part of cleanroom ventilation systems. They ensure Class 100 or ISO 5 standards for sterile production zones where drugs, vaccines, and medical devices are manufactured.

These filters help maintain laminar airflow, which ensures a continuous, clean air stream that prevents cross-contamination. Rooms equipped with HEPA filtration maintain stable temperature, humidity, and particle counts for reliable process control.

Regulatory Compliance

HEPA filtration also supports compliance with international standards such as:

- ISO 14644 for cleanroom classification.

- Good Manufacturing Practices (GMP) requirements.

- US FDA and EU EMA pharmaceutical cleanroom guidelines.

By incorporating HEPA filtration into its equipment and systems, Everheal ensures that its global clients meet stringent regulatory demands for pharmaceutical production.

Types of HEPA Air Filters

Although the core concept is the same, HEPA filters are categorized based on efficiency levels and applications.

1. True HEPA Filters

"True HEPA" filters meet official DOE or EN1822 standards. They remove ≥99.97% of particles at 0.3 microns. These are standard equipment in cleanrooms, hospitals, and high-tech manufacturing environments.

2. HEPA-Type Filters

HEPA-type filters resemble HEPA filters but do not meet strict filtration efficiency. They typically remove 90–95% of airborne particles. These filters may be sufficient for domestic air purifiers but not for industrial or pharmaceutical use.

3. ULPA Filters

ULPA (Ultra-Low Penetration Air) filters go beyond HEPA standards, trapping 99.999% of particles down to 0.12 microns. ULPA filters are used in highly sensitive environments like microelectronics or aerospace research labs.

Benefits of Using HEPA Air Purifiers

The benefits of using HEPA Air Filters and purifiers extend across multiple domains—health, productivity, and industrial quality control.

1. Superior Air Quality

HEPA Air Filters remove bacteria, viruses, and particulates, creating a sterile working environment ideal for pharmaceutical manufacturing and hospital applications.

2. Allergens and Pathogen Control

They protect workers from inhaling allergens, microbial spores, and toxic particulates, reducing sick days and workplace contamination risks.

3. Longevity of Equipment

By minimizing airborne dust and debris, HEPA filtration protects manufacturing machinery, sensors, and ventilation systems from dust buildup and damage.

4. Energy Efficiency with Proper Design

When integrated with optimized airflow systems, HEPA purifiers maintain efficiency while preventing air resistance that could stress HVAC systems.

5. Regulatory and Export Advantages

HEPA-certified equipment gives companies like Everheal's clients a strong edge in complying with global safety certifications, enhancing trust and market competitiveness.

Maintenance and Replacement of HEPA Air Filters

Regular maintenance ensures the long-term performance of HEPA-equipped systems. A clogged filter not only reduces airflow but can also compromise purification efficiency.

Maintenance Best Practices

- Scheduled Inspections: Check pressure drops or airflow resistance monthly.

- Replacement Schedule: Replace filters every 6–12 months depending on usage and environment.

- Pre-Filter Maintenance: Clean or replace pre-filters to extend HEPA filter lifespan.

- Certification Tests: For cleanrooms, conduct particulate count and airflow validation tests after filter changes.

Everheal's purification systems integrate easy-access filter housings, differential pressure sensors, and alarm indicators to simplify maintenance operations.

Choosing the Right HEPA Air Purifier

Selecting the proper HEPA system depends on application size, particle load, and cleanroom classification.

Key Considerations

1. Filtration Efficiency: Choose a True HEPA or ULPA filter as required.

2. Airflow Rate (CFM): Match capacity to room volume.

3. Noise Level: Consider sound-sensitive sectors like hospitals.

4. Energy Use: Opt for systems with efficient motors and intelligent fan controls.

5. Integration: Ensure compatibility with existing HVAC or cleanroom systems.

Everheal provides customized HEPA filtration solutions for pharmaceutical, medical, and food industries, ensuring seamless integration within factory layouts and production line setups.

HEPA Air Filter Technology and Global Sustainability

Beyond immediate cleanliness, HEPA Air Filters also impact sustainability. They reduce chemical air treatment needs and foster energy-efficient cleanroom designs.

Modern HEPA systems can be coupled with smart sensors, UV disinfection, or IoT monitoring to balance filtration efficiency with predictive maintenance. Companies seeking sustainable compliance and low carbon operation benefit greatly from adopting intelligent HEPA filtration systems as part of their environmental strategy.

Conclusion

The HEPA Air Filter represents the pinnacle of air purification technology, delivering unmatched performance in removing airborne contaminants. In sectors like pharmaceuticals, biotechnology, and high-precision manufacturing, the HEPA Air Filter ensures clean, compliant, and safe working environments. Companies such as Everheal leverage this technology to create comprehensive sterile solutions—from pure water systems and steam generators to entire cleanroom layouts—tailored for global clients in regulated industries.

Implementing HEPA filtration is not merely about improving air—it's a commitment to quality, safety, and regulatory excellence. As manufacturing environments evolve, the HEPA Air Filter remains a cornerstone of clean and sustainable production.

FAQs About HEPA Air Filters

1. What is the Difference Between HEPA and ULPA Filters?

HEPA filters trap 99.97% of particles ≥0.3 microns, while ULPA filters capture 99.999% of particles ≥0.12 microns. ULPA filters are more efficient but generate higher pressure drops and energy use.

2. How Long Do HEPA Filters Last?

Typical HEPA Air Filters last between 6 and 12 months under industrial use. However, frequency may increase in environments with heavy dust or biological contaminants.

3. Can HEPA Air Filters Remove Viruses?

Yes. While viruses are smaller than 0.3 microns, HEPA filters effectively capture them due to diffusion and interception mechanisms. Many healthcare facilities rely on them for infection prevention.

4. Are HEPA Air Purifiers Suitable for Large Facilities?

Absolutely. Industrial and pharmaceutical-grade HEPA Air Purifiers can handle high air volumes and are designed for integration into centralized ventilation systems.

5. How Often Should HEPA Filters Be Tested?

For cleanroom applications, filters are tested at least once annually according to ISO standards or after major maintenance actions to confirm performance integrity.