Content Menu

● The Origins of the Banana Bag Infusion

● Understanding the Composition

● The Role of Infusion Bags in Modern Therapeutics

>> Key Features of Pharmaceutical-Grade Infusion Bags:

● Medical Applications of the Banana Bag Infusion

>> Primary Applications:

● How Banana Bag Infusions Are Prepared

● Benefits of Banana Bag Infusion Therapy

>> 1. Rapid Nutrient Delivery

>> 2. Hydration Support

>> 3. Customizable Formulation

>> 4. Preventive Function in High-Risk Patients

>> 5. Efficient Hospital Workflow

● Modern Manufacturing of Infusion Bags

>> Manufacturing Process Overview:

● Importance of Sterility and Quality Control

● Future Innovations in Infusion Bag Technology

● Conclusion

● FAQ

>> 1. What gives the Banana Bag Infusion its yellow color?

>> 2. Can Banana Bag Infusions be customized for specific medical needs?

>> 3. How long does a Banana Bag Infusion take to administer?

>> 4. Are Banana Bags only for alcohol withdrawal patients?

>> 5. What materials are used in Infusion Bags for Banana Bag preparation?

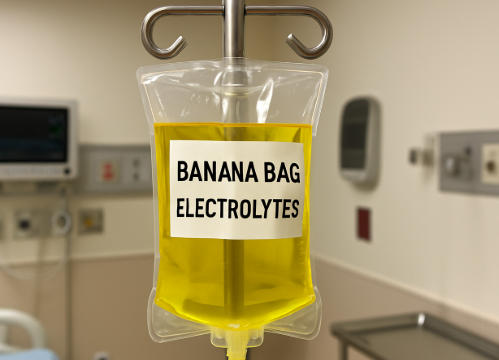

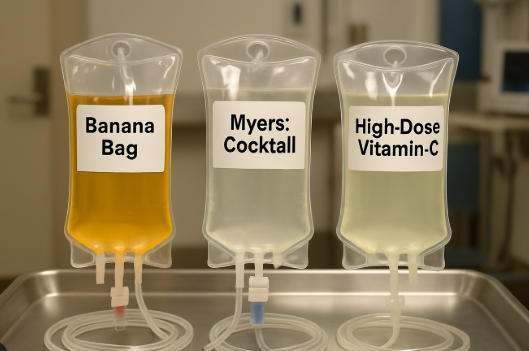

In the realm of clinical and pharmaceutical care, Infusion Bags play a transformative role in delivering vital nutrients and medicines directly to patients' veins. Among them, the Banana Bag Infusion stands out for its distinctive yellow color and powerful nutritional punch. Often used in hospitals and emergency settings, this sterile solution has saved countless lives by rapidly correcting multiple deficiencies caused by chronic illness, alcohol dependency, or malnutrition.

This article explores what a Banana Bag Infusion is, its composition, applications, and how pharmaceutical-grade Infusion Bags contribute to safe and precise administration in modern healthcare systems.

The Origins of the Banana Bag Infusion

The Banana Bag Infusion derived its name from its bright yellow hue, a result of combining vitamins that naturally impart color to the solution. It first appeared in the mid-20th century when clinicians sought a concise and efficient intravenous blend that could restore hydration, electrolytes, and essential vitamins in compromised patients.

Initially used in emergency departments and detox wards to treat patients suffering from alcohol withdrawal, the Banana Bag quickly became a staple in hospitals worldwide. It is an easily prepared, multi-component Infusion Bag that provides both hydration and vital nutrients intravenously in a sterile and controlled manner.

Understanding the Composition

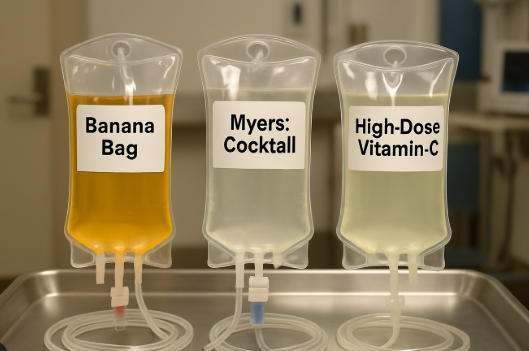

A Banana Bag Infusion generally contains a mixture of vitamins, electrolytes, and fluids. While the exact formulation can vary between facilities or patients' needs, a standard 1-liter Infusion Bag usually includes the following primary components:

1. Thiamine (Vitamin B1) — Crucial for carbohydrate metabolism and nerve function. Chronic alcohol use often causes severe thiamine deficiency, leading to conditions like Wernicke's encephalopathy.

2. Multivitamins — These provide additional B-complex vitamins (such as B2, B6, B12) and vitamin C, replenishing nutrients that support metabolism and immune functions.

3. Folic Acid — Vital for DNA synthesis and red blood cell production, folic acid helps prevent anemia, a common issue in malnourished individuals.

4. Magnesium Sulfate — Replaces essential minerals lost due to dehydration, vomiting, or diuretic use, and assists in muscle and nerve coordination.

5. Normal Saline (0.9% Sodium Chloride) or Dextrose 5% Solution — Acts as the carrier fluid providing hydration while facilitating nutrient absorption.

The resulting mixture offers a combination of rehydration and repletion that makes it indispensable in acute care. These ingredients, precisely measured and sterilized, are stored within high-quality Infusion Bags that comply with international regulatory standards for pharmaceutical safety.

The Role of Infusion Bags in Modern Therapeutics

An Infusion Bag is not merely a container—it's a sophisticated, medical-grade system manufactured to ensure chemical stability, sterility, and compatibility with a wide range of active ingredients. The material composition often includes multilayer polymer films that are non-reactive, phthalate-free, and capable of withstanding sterilization processes such as autoclaving.

Key Features of Pharmaceutical-Grade Infusion Bags:

- Chemical resistance: Prevents interactions between fluid components and the bag wall.

- Transparency: Allows healthcare providers to visually inspect the contents and check for contamination or precipitation.

- Durability: Designed to endure long-term storage and transportation without leakage.

- Sterility assurance: Manufactured in cleanroom environments to prevent microbial contamination.

Companies like Everheal specialize in producing advanced Infusion Bag manufacturing solutions and systems for pharmaceutical-grade applications. Through automated filling, sealing, and sterilization equipment, Everheal supports global clients with custom plant layout designs and turnkey production lines that meet stringent GMP (Good Manufacturing Practice) standards.

Medical Applications of the Banana Bag Infusion

The Banana Bag Infusion is widely used in hospital settings for several critical purposes. Its versatility comes from its ability to address both acute deficiencies and chronic depletion of key nutrients.

Primary Applications:

- Alcohol Withdrawal and Chronic Alcoholism Treatment: Helps restore thiamine, folate, and electrolytes often depleted in these patients.

- Severe Malnutrition: Offers rapid replenishment of key vitamins and minerals in individuals with extended periods of poor dietary intake.

- Post-Surgical Recovery: Rehydrates and restores vitamins for patients unable to eat or digest properly after surgery.

- Intensive Care Rehydration: Used in critical cases where oral or enteral feeding isn't possible.

- Electrolyte Correction: Stabilizes sodium, potassium, and magnesium levels in patients suffering from metabolic imbalances or dehydration.

In all these cases, the safety and efficacy of the Banana Bag depend heavily on the design, material, and sterility control of the Infusion Bag used in preparation and administration.

How Banana Bag Infusions Are Prepared

Preparation involves a series of meticulously controlled steps within a sterile environment. Typically, healthcare professionals or pharmacists follow a validated compounding protocol:

1. Selecting the Base Fluid: A liter of 0.9% saline or 5% dextrose solution is poured into a sterile Infusion Bag.

2. Adding Electrolytes and Vitamins: Individual vials of thiamine, folic acid, magnesium sulfate, and multivitamins are injected into the bag via sterile connectors.

3. Mixing and Inspection: The infused solution is mixed gently to ensure uniform distribution. Visual inspection verifies clarity and color consistency.

4. Labeling: The Infusion Bag is properly labeled with date, composition, expiration, and patient details.

5. Administration: The prepared solution is delivered intravenously through an IV line using aseptic techniques to prevent contamination.

High-performance Infusion Bag production systems like those manufactured by Everheal make large-scale, sterile solution compounding feasible while minimizing contamination risk.

Benefits of Banana Bag Infusion Therapy

1. Rapid Nutrient Delivery

Intravenous infusion allows nutrients and electrolytes to enter the bloodstream immediately, bypassing the digestive system. This enables faster correction of deficiencies.

2. Hydration Support

For patients who cannot drink or are severely dehydrated, Infusion Bags serve as a reliable method to restore fluid balance effectively.

3. Customizable Formulation

Clinicians can tailor the Banana Bag composition by adjusting vitamin and electrolyte concentrations depending on patient needs.

4. Preventive Function in High-Risk Patients

It's frequently administered to chronic alcoholics and malnourished individuals before they develop life-threatening complications like encephalopathy.

5. Efficient Hospital Workflow

Pre-filled, ready-to-use Infusion Bags minimize preparation time, errors, and contamination, improving clinical efficiency across departments.

Modern Manufacturing of Infusion Bags

The production of Infusion Bags used in Banana Bag therapy demands precision engineering. The entire process—from raw material inspection to final sterilization—is carefully automated in GMP-certified facilities.

Manufacturing Process Overview:

1. Film Forming and Cutting: Medical-grade polymer films are thermoformed into flexible bag structures.

2. Bag Forming, Filling, and Sealing: Automated filling lines—like those manufactured by Everheal—ensure precise liquid dosing under sterile conditions.

3. Leak Testing: Each bag undergoes stringent quality tests to confirm sealing integrity.

4. Labeling and Sterilization: After labeling, the Infusion Bags are sterilized using autoclaving or gamma irradiation to ensure microbial safety.

Advanced equipment, such as Everheal's Liquid Filling and Sealing Machines, Pure Steam Generators, and Water for Injection (WFI) Systems, form the technological backbone of reliable Infusion Bag production worldwide.

Importance of Sterility and Quality Control

Given that Infusion Bags deliver contents directly into a patient's bloodstream, sterility is non-negotiable. Contaminated fluids can lead to systemic infections or fatal complications. To ensure safety, pharmaceutical manufacturers implement multiple layers of quality assurance:

- Microbial Testing: Checks for bacterial and fungal contamination.

- Endotoxin Testing: Ensures no pyrogenic (fever-causing) substances are present.

- Chemical Stability Tests: Confirms that vitamins and electrolytes remain stable within the bag until use.

- Container Integrity Checks: Detects pinholes, leaks, or compromised seals that might affect sterility.

Everheal integrates real-time monitoring, automated control, and digital validation systems across its Infusion Bag production lines to guarantee compliance with international pharmacopoeial standards.

Future Innovations in Infusion Bag Technology

The future of intravenous therapy lies in smarter, more sustainable Infusion Bag systems. Pharmaceutical engineering is evolving to produce eco-friendly materials, enhanced barrier protection, and digitally traceable packaging.

Key industry innovations include:

- Single-use biopolymer Infusion Bags that are biodegradable.

- Pre-filled sterile nutrient bags reducing human intervention.

- Integrated sensors tracking fluid temperature, flow rates, and chemical stability.

- Automated filling systems with robotic precision for consistent and contamination-free compounding.

Everheal is actively investing in R&D to advance these technologies, providing flexible and scalable solutions for global pharmaceutical manufacturers.

Conclusion

The Banana Bag Infusion exemplifies the synergy between medical science and engineering—the careful blend of vitamins, electrolytes, and hydration solutions packaged in a sterile Infusion Bag that delivers life-saving results. Behind every successful infusion lies decades of research, stringent manufacturing standards, and precise instrumentation.

From emergency rooms to long-term care, these bright yellow bags symbolize recovery, revitalization, and resilience. With companies like Everheal powering the manufacturing backbone of Infusion Bags and sterile system equipment, the future of intravenous therapy continues to shine as brightly as the Banana Bag itself.

FAQ

1. What gives the Banana Bag Infusion its yellow color?

The yellow color comes primarily from multivitamins, especially riboflavin (vitamin B2), which naturally imparts a bright yellow tint to the fluid inside the Infusion Bag.

2. Can Banana Bag Infusions be customized for specific medical needs?

Yes. The formulation of a Banana Bag Infusion can be adjusted according to a patient's needs—adding or reducing certain vitamins, electrolytes, or fluid volumes.

3. How long does a Banana Bag Infusion take to administer?

Typically, it's infused over 1 to 2 hours depending on patient condition and infusion rate prescribed by the doctor.

4. Are Banana Bags only for alcohol withdrawal patients?

No. They are also used for post-surgical recovery, malnutrition, dehydration, and critically ill patients who need rapid nutrient and electrolyte replenishment.

5. What materials are used in Infusion Bags for Banana Bag preparation?

Most Infusion Bags are made from medical-grade multilayer polymers (like PP or PVC-free films) that maintain sterility, chemical stability, and durability throughout the storage period.