Views: 222 Author: Rebecca Publish Time: 2025-12-14 Origin: Site

Content Menu

● Why HEPA Air Filters Are Essential

● Factors That Affect HEPA Filter Replacement Frequency

>> 1. Air Quality and Pollution Level

>> 4. Pre-Filtration System Efficiency

>> 5. Manufacturer's Recommendations

● Signs It's Time to Replace the HEPA Air Filter

● How to Replace a HEPA Air Filter Properly

● Extending HEPA Filter Lifespan

● HEPA Air Filters in Pharmaceutical Environments

● Environmental and Cost Considerations

● Best Practices for HEPA Filter Management in Industrial Applications

● FAQ

>> 1. How often should I change a HEPA Air Filter?

>> 2. Can I clean and reuse a HEPA Air Filter?

>> 3. What's the difference between HEPA and activated carbon filters?

>> 4. Are there signs that my HEPA filter needs replacement sooner?

>> 5. Why are HEPA filters critical in pharmaceutical production?

Maintaining indoor air quality is a top priority for laboratories, pharmaceutical production facilities, hospitals, and even households. One of the most critical elements of this process is the HEPA Air Filter used in air purifiers. These filters trap 99.97% of airborne particles as small as 0.3 microns, ensuring that the air remains clean and contaminant-free. However, their efficiency depends heavily on proper maintenance—particularly, knowing how often to change the HEPA filter.

This guide discusses the factors influencing replacement frequency, the signs your filter needs attention, maintenance tips, and the role of HEPA Air Filters in highly controlled environments such as pharmaceutical manufacturing.

A HEPA Air Filter (High-Efficiency Particulate Air filter) is designed to capture extremely fine airborne particles, including dust, bacteria, pollen, smoke, and even viruses. To qualify as true HEPA, a filter must meet strict standards set by organizations such as the U.S. Department of Energy (DOE) or the European EN1822 classification.

HEPA filters are typically made from a dense mat of fibers arranged to intercept particles through mechanisms like diffusion, interception, and impaction. The result is an exceptionally high filtration efficiency that surpasses other common filter types.

In pharmaceutical and medical environments, these filters are not just for comfort—they're crucial for compliance with GMP (Good Manufacturing Practices) and for protecting both products and personnel from contamination.

The importance of HEPA Air Filters extends far beyond simple dust removal. In industries like healthcare, biotechnology, and pharmaceuticals, air purity correlates directly with product quality and safety. HEPA filters maintain controlled environmental conditions by:

- Preventing airborne contaminants from entering cleanrooms.

- Controlling microbial load during product filling and packaging.

- Ensuring compliance with ISO and GMP cleanliness standards.

- Protecting sensitive materials and preventing cross-contamination.

Without proper filtration, even minor particulate exposure could lead to costly product rejections or safety risks. Hence, replacing HEPA filters at the correct interval becomes a critical maintenance activity.

Determining how often to change your HEPA Air Filter depends on several environmental and operational factors. Let's explore the most influential ones.

If your purifier is operating in a region with heavy air pollution, high dust content, or chemical exposure, your HEPA filter will clog faster. Urban or industrial areas might require replacement every 6–12 months, compared to a cleaner environment where filters can last up to two years.

Continuous operation significantly shortens a filter's lifespan. For devices used 24/7, the HEPA filter might need replacement twice a year. On the other hand, air purifiers that run intermittently in offices or homes might last longer—around 12 to 18 months.

In pharmaceutical facilities or laboratories, air purity standards are strictly regulated. Controlled spaces require frequent air filter inspection and replacement—often scheduled quarterly—to ensure compliance and maintain cleanroom classification.

Air purifiers equipped with pre-filters or activated carbon layers help extend the life of HEPA filters. A high-quality pre-filter traps larger particles such as lint and dust, reducing HEPA filter load and maintenance frequency.

Manufacturers test their air purifiers under specific conditions. Always follow the time frame they suggest—typically every 6 to 12 months for consumer devices and every 3 to 6 months for industrial models.

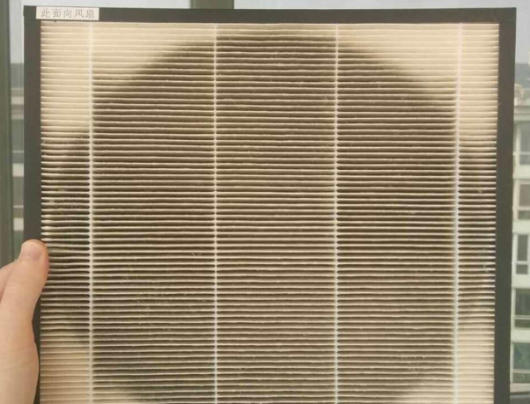

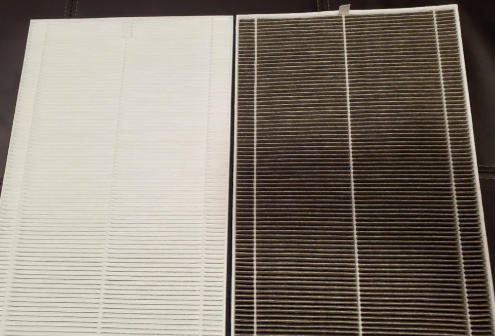

Regardless of the schedule, your HEPA Air Filter will eventually show signs of wear and reduced efficiency. Look out for these indications:

- Reduced airflow: When airflow decreases, it often means the filter is clogged.

- Increased noise level: The purifier may work harder to push air through a blocked filter.

- Dust buildup around vents: External dust indicates internal saturation.

- Unpleasant odors: Odors suggest accumulated pollutants the filter can't handle anymore.

- Allergy symptoms returning: Sneezing or irritation may mean airborne particles are slipping through.

Regularly checking your system indicator (if your purifier has one) can also prevent overuse of the HEPA filter.

Changing a HEPA Air Filter is relatively straightforward, but adherence to careful procedure ensures both safety and performance continuity.

1. Switch off and unplug the purifier. Always disconnect power for safety.

2. Remove the outer covering or latch. Access the filter compartment carefully.

3. Take out the used HEPA filter. Avoid shaking or tapping it, which could release trapped particles.

4. Clean the inner chamber. Wipe surfaces gently with a damp cloth to remove residual dust.

5. Insert the new filter. Make sure it fits snugly with no gaps or loose fitting.

6. Reset the filter timer or indicator. Many modern purifiers track usage electronically.

Store spare filters in clean, dry environments to maintain their protective quality before installation.

Although you must replace filters periodically, you can extend lifespan through proper maintenance. Here's how:

- Vacuum pre-filters regularly. Removes coarse dust.

- Operate in clean conditions. Regular floor and surface cleaning reduces airborne contaminants.

- Monitor humidity. Excessive moisture can damage filter fibers or encourage microbial growth.

- Avoid blocking vents. Ensure adequate airflow around the purifier.

- Schedule routine inspections. Especially critical in industrial or pharmaceutical applications.

Such habits can reduce replacement frequency, optimizing both costs and performance.

Companies like Everheal, which specialize in pharmaceutical equipment and cleanroom systems, understand the strategic importance of HEPA Air Filters. Whether integrated into a pure steam generator, filling machine, or sterilization system, HEPA filtration is pivotal for maintaining sterile air inside production and packaging areas.

In these environments, HEPA filters are incorporated into multiple points of the air handling system, including:

- Terminal air diffusers in cleanrooms.

- Laminar flow cabinets and isolators.

- Sterile filling machine enclosures.

- HVAC systems supplying Class A or B rooms.

For GMP compliance, filters undergo integrity tests (such as DOP or PAO tests) at installation and at regular intervals thereafter. Even minor leaks or clogging could threaten product sterility, emphasizing the need for professional maintenance and timely replacement.

Replacing a HEPA Air Filter involves both cost and environmental factors. Though initially more expensive, premium filters typically last longer and maintain efficiency over time.

Some eco-friendly designs also incorporate recyclable components or washable pre-filters to minimize waste. For organizations concerned with sustainability, proper disposal and recycling of used filters should follow local environmental regulations due to the potential biological contaminants they may contain.

When viewed through a total-cost-of-ownership lens, regular maintenance not only preserves air quality but also prevents excessive energy consumption caused by clogged filters, saving costs in the long run.

For pharmaceutical manufacturers, following structured maintenance and documentation is vital. Recommended best practices include:

- Maintain detailed filter replacement logs for each air-handling unit.

- Schedule preventive maintenance rather than waiting for filter failure.

- Use certified replacement filters meeting EN1822 or ISO 29463 standards.

- Conduct smoke or aerosol leakage tests after each replacement.

- Train staff in safe handling procedures for contaminated filters.

These steps ensure consistent air purity and reliable compliance audits.

Changing a HEPA Air Filter isn't just a technical task—it's a crucial part of ensuring health, safety, and product integrity in any controlled environment. The general frequency varies from 6 to 18 months depending on conditions, but in pharmaceutical or industrial settings, scheduled maintenance and periodic testing are mandatory.

Ultimately, understanding the characteristics and role of HEPA filters helps users maximize filter efficiency, prolong equipment life, and maintain exceptional air quality standards.

In typical residential use, every 6–12 months is sufficient. Industrial or pharmaceutical environments may require quarterly replacement based on usage and regulatory compliance.

No. True HEPA filters are non-washable. Attempting to clean them may damage the fiber structure, reducing filtration efficiency.

HEPA filters trap particles like dust and microbes, while activated carbon filters absorb gases, odors, and volatile organic compounds (VOCs). They work best together.

Yes. Reduced airflow, increased noise, and persistent odors often indicate a clogged or ineffective filter that needs replacement.

They maintain sterile environments by preventing microbial contamination in cleanrooms and manufacturing areas, ensuring product safety and GMP compliance.

Ever wondered how often to change your HEPA Air Filter? This detailed guide explains replacement frequency, maintenance methods, and why HEPA filters are vital for air purity in homes, labs, and pharmaceutical environments. Learn how to keep your air perfectly clean.

Explore how much a HEPA air filter costs and what affects its price. Learn about HEPA filter types, applications in pharmaceutical systems, maintenance, and buying tips. Discover why Everheal’s HEPA air filters guarantee GMP-level purity and performance for industrial clients.

This article explains how long a HEPA air filte lasts, the factors affecting its lifespan, maintenance best practices, and replacement guidelines. It also highlights Everheal’s integrated filtration and factory design solutions for pharmaceutical manufacturing compliance.

Air quality plays a crucial role in industries such as pharmaceuticals, healthcare, and electronics manufacturing. In these sectors, even the smallest airborne particles can compromise the integrity of production environments or damage sensitive equipment. Among the many solutions developed to ensur

Blueair purifiers use advanced HEPASilent™ technology that matches or exceeds True HEPA Air Filter performance. Learn how their hybrid system works, its benefits, and whether it suits home, industrial, or pharmaceutical environments.

This in-depth guide explores whether washable central air filters harm HVAC systems. Learn about their pros, cons, maintenance tips, and effects on air quality to decide if washable air filters suit your home or manufacturing facility.

Explore whether washable cabin air filters exist, how they work, and their benefits for cost, environment, and performance. Learn why washable air filters are ideal for vehicles, factories, and clean industrial systems like those developed by Everheal.

Discover whether Harley S&S Stage 1 air filters are washable and why they’re ideal for long-term performance. Learn cleaning steps, maintenance tips, and FAQs about washable air filters to keep your Harley running smoothly and efficiently.

Learn whether Stihl chainsaw air filters are washable and how to clean them properly. Discover the benefits of a Washable Air Filter, maintenance tips, replacement guidelines, and FAQs to keep your Stihl chainsaw running efficiently and extending engine life.

This comprehensive guide explores whether the air filter in the Stihl 029 chainsaw is washable, providing detailed information on the design, cleaning process, benefits, and maintenance tips for a washable air filter. The article also includes a conclusion and a set of frequently asked questions to help users maximize the lifespan and performance of their chainsaw.

Blueair purifiers use HEPASilent™ filtration technology to deliver HEPA Air Filter performance with enhanced quietness, energy efficiency, and higher particle capture. Learn how Blueair ensures cleaner air for households, offices, and even pharmaceutical-grade environments.

Discover whether you need a HEPA Air Filter for your air purifier. Learn how HEPA filters work, their importance in homes and pharmaceutical industries, and how Everheal’s advanced purification systems use HEPA technology to ensure safe, clean, and compliant air quality worldwide.

Learn how HEPA Air Filters work and why they’re the gold standard in air purification. Explore their mechanisms, applications in pharmaceuticals, hospitals, and homes, along with benefits, limitations, and maintenance tips for cleaner, healthier environments.

This article explores whether you can wash a HEPA filter air purifier, explaining the risks of washing True HEPA filters, how to maintain them properly, and how Everheal’s pharmaceutical systems integrate reliable HEPA air filtration for guaranteed purity and performance.

Maintaining HEPA air filters is critical for ensuring the highest air quality standards in pharmaceutical and manufacturing environments. Although it might be tempting to wash or reuse HEPA filters to save costs, doing so can compromise their integrity and filtration capability. Proper handling, timely replacement, and preventive maintenance practices are the best ways to sustain effective filtration. Always adhere to manufacturer guidelines and industry standards to guarantee a safe and contaminant-free environment.

In the modern industrial and residential air filtration market, the demand for sustainable, cost-effective, and high-performance filtration solutions has grown tremendously. Among the various options available, the washable air filter has become one of the most talked-about innovations. But what exactly makes it the best choice? How does it compare with disposable filters? And which washable air filter models stand out for efficiency and durability?

Discover whether a washable air filter is a good choice for your home or industrial system. Learn its benefits, maintenance tips, and limitations, and explore how washable air filters support sustainable air management in pharmaceutical and manufacturing environments.

Discover how air purifiers with washable filters improve air quality while cutting costs and environmental impact. Learn their benefits, applications, maintenance tips, and how they support sustainable manufacturing in homes, industries, and pharmaceutical facilities.

K&N washable air filters are durable, eco-friendly, and designed for lifetime use. Learn how to clean, maintain, and maximize performance from your washable air filter while reducing waste and boosting efficiency across automotive and industrial systems.

This detailed guide explains whether air purifier filters are washable, exploring how washable air filters work, their pros and cons, cleaning methods, and ideal applications in homes and industries like pharmaceuticals—helping users achieve efficient and sustainable air purification.