Views: 222 Author: Rebecca Publish Time: 2025-12-14 Origin: Site

Content Menu

● Typical Lifespan of a HEPA Air Filter

>> Average Lifespan by Application

● Factors That Affect Filter Longevity

>> 1. Air Quality and Environmental Conditions

>> 2. Operating Hours and Airflow Rate

>> 3. Maintenance and Pre-Filtration

>> 4. Humidity and Temperature

>> 5. Installation and Seal Integrity

● How to Know When to Replace a HEPA Air Filter

>> Key Signs That a Filter Needs Replacement

● Extending the Life of Your HEPA Air Filter

>> 1. Use Multi-Stage Filtration

>> 2. Maintain Stable Airflow Rates

>> 4. Schedule Preventive Maintenance

>> 5. Store Spare HEPA Filters Properly

● Importance of HEPA Filters in Pharmaceutical Facilities

● Best Practices for Testing and Verification

● Everheal's Integrated Filtration Solutions

● FAQ

>> 1. What does a HEPA air filter remove?

>> 2. How can I check if a HEPA filter is still effective?

>> 3. Can HEPA air filters be cleaned and reused?

>> 4. What happens if I delay replacing a clogged HEPA filter?

>> 5. How do I dispose of used HEPA filters safely?

In modern pharmaceutical production, air purity is more than a matter of comfort — it defines product safety and compliance. HEPA air filters have become a core component in cleanroom environments, laboratories, and equipment manufacturing facilities where air cleanliness is mission-critical. At Everheal, a global supplier of pharmaceutical water systems, distillation and sterilization equipment, and integrated plant design, we understand that reliable air filtration ensures not only product integrity but also operational longevity.

This article explores one fundamental question: How long does a HEPA air filter last? More importantly, it examines what factors determine its lifetime, how to maintain it properly, and when replacement becomes necessary to preserve a contamination-free environment.

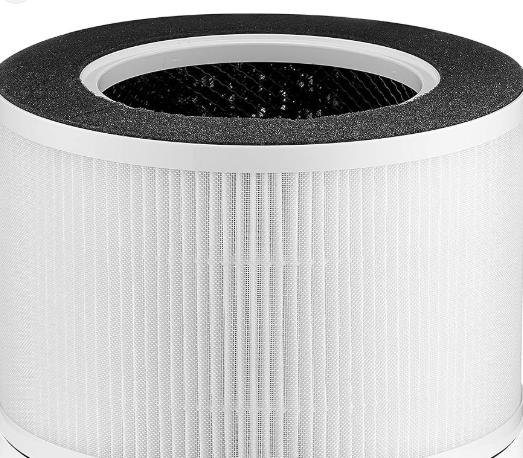

A HEPA (High-Efficiency Particulate Air) filter is a specialized filtration system designed to trap harmful airborne particles, including dust, pollen, microorganisms, and aerosols. According to international standards (such as EN 1822 and ISO 29463), a true HEPA filter must remove at least 99.97% of particles that are 0.3 microns in diameter.

In pharmaceutical facilities, HEPA filters are commonly used in:

- Cleanrooms and biosafety labs

- Pure steam generators and sterile filling lines

- Purified water preparation areas

- HVAC units within production and packaging zones

The reason for this strict requirement is clear: even minimal airborne contamination can compromise product quality during critical operations.

The general lifespan of a HEPA air filter varies depending on how and where it is used. In regulated industrial environments such as pharmaceutical manufacturing, the lifespan typically ranges from 1 to 3 years.

However, under optimized operating conditions — with proper maintenance and controlled airflow — well-engineered filters can sometimes perform effectively for up to 5 years.

| Application Environment | Typical Lifespan | Notes |

|---|---|---|

| Pharmaceutical cleanroom | 1–3 years | Requires regular particle count testing |

| Hospital or health facility | 1–2 years | Continuous high-load operation |

| Laboratory clean benches | 2–4 years | Moderate particulate exposure |

| Industrial HVAC systems | 3–5 years | Maintenance-dependent |

| Residential air purifiers | 1 year | Subject to dust accumulation |

It's clear that operation intensity and environmental conditions significantly impact durability. For instance, a HEPA air filter used in sterile filling machines will wear faster than one used in a low-traffic environment.

Filters in areas with high particulate loads or poor incoming air quality clog faster. Dust, smoke, or chemical vapors degrade the medium and increase pressure drop.

Continuous operation at high air velocity forces more particles into the filter, reducing its lifespan. In pharmaceutical environments that run 24/7, this effect is especially pronounced.

Installing pre-filters upstream of the HEPA unit can trap larger particles, extending the HEPA unit's lifetime. Regular cleaning of upstream ducts and fans also prevents premature clogging.

Moisture and heat can compromise the integrity of filter materials. Operating within manufacturer-specified temperature and humidity limits ensures longer service life.

Even the best HEPA air filter performs poorly if improperly installed. Leaks at joints or frames allow unfiltered air to bypass the filter. Routine DOP testing and visual inspections are critical for ensuring full efficiency.

Determining the correct replacement time relies on both scientific monitoring and practical indicators.

- Increased Pressure Drop: Measured through built-in gauges, a significant resistance increase indicates clogging.

- Reduced Airflow Performance: Noticeable decline in air circulation efficiency suggests blockage or damage.

- Failed Integrity Tests: Regular HEPA integrity (DOP or PAO) tests detect leaks or compromised efficiency.

- Visual Signs of Contamination: Dust accumulation or discoloration on the filter frame can be a red flag.

- Deviation in Cleanroom Class Metrics: If particle counts near the filter outlet increase, it's time to replace.

For pharmaceutical equipment such as sterile filling machines or pure steam generators, timely filter replacement is tied to maintaining production compliance with GMP (Good Manufacturing Practice) standards.

Although HEPA filters naturally degrade with time, certain strategies can significantly extend their operational period.

Incorporate pre-filters, medium filters, and HEPA filters in sequence. This design reduces the burden on the HEPA element, catching coarse contaminants early.

Overloading the filter with high airflow shortens its life. Balance fan capacity with filter resistance for consistent performance.

Regular cleaning around air intakes and outlets minimizes external dust intrusion that can accelerate degradation.

Periodic inspections, air quality assessments, and scheduled replacements prevent costlier downtime. Always follow the maintenance cycle recommended by the manufacturer.

HEPA filters should be stored in sealed packaging, away from moisture and direct sunlight. Environmental exposure during storage can weaken filter fibers or frame adhesives.

For pharmaceutical companies, HEPA air filters represent a critical safety barrier. They ensure that filling, capping, sterilizing, and packaging processes occur in contamination-free conditions.

At Everheal, our production systems — including pure water preparation systems, pure steam generators, multifunctional distillation units, and sterilization equipment — rely on precision air filtration technology. Reliable HEPA systems guarantee that air purity matches international GMP standards, preventing cross-contamination during drug manufacturing.

By maintaining optimal filter performance, companies reduce operational risk, improve compliance documentation, and ensure product integrity from start to finish.

Routine testing ensures that the HEPA air filter continues to provide high capture efficiency. Common testing methods include:

- DOP/PAO integrity tests to detect leaks or holes

- Particle counting tests to evaluate downstream cleanliness levels

- Pressure drop measurement to monitor airflow resistance

- Smoke visualization for airflow pattern verification

Pharmaceutical-grade systems usually require revalidation at set intervals, especially after maintenance, filter change, or layout modification.

Everheal not only supplies production-grade air filtration systems but also provides customized cleanroom layout design for pharmaceutical clients worldwide. Our engineering teams integrate HEPA filter stations into broader purification and sterilization systems to ensure seamless operation.

Our turnkey cleanroom and water system solutions include:

- Purified water system design with integrated pre-filtration

- Pure steam generation optimized for microbiological safety

- Multifunctional water distillation with controlled air purity environments

- Liquid filling and sealing machinery utilizing HEPA-protected laminar flow

- Sterilization systems validated for routine GMP compliance

Whether designing a new facility or upgrading existing production lines, Everheal ensures that HEPA filtration performance aligns with rigorous pharmaceutical standards.

A HEPA air filter typically lasts between 1 and 3 years, though lifespan can extend beyond 5 years with optimal maintenance and controlled environmental conditions. Factors such as air quality, operation frequency, humidity, and maintenance directly influence durability.

For pharmaceutical manufacturers, timely filter monitoring and replacement are not just operational habits — they are core compliance and product purity requirements. Using high-quality HEPA filters, combined with reliable system engineering and preventive maintenance, ensures that production environments remain sterile, safe, and fully aligned with international GMP expectations.

Everheal's integrated systems demonstrate how advanced filtration technology can safeguard every stage of pharmaceutical production, from water preparation to final product sterilization.

A HEPA air filter captures very fine particles such as dust, bacteria, mold spores, aerosols, and other contaminants as small as 0.3 microns with an efficiency of 99.97% or higher.

You can test the filter through DOP/PAO integrity testing, pressure drop monitoring, and particle count analysis to verify performance stability and identify any leaks.

In most pharmaceutical and cleanroom applications, HEPA filters are not reusable. Attempting to wash or vacuum them may damage the fine fibers and compromise efficiency.

Delays can increase airflow resistance, reduce system efficiency, and risk contamination in critical production zones. In GMP environments, this may lead to non-compliance.

Used filters should be sealed in protective bags and disposed of as hazardous waste according to local environmental regulations, especially if they have trapped biological materials.

Ever wondered how often to change your HEPA Air Filter? This detailed guide explains replacement frequency, maintenance methods, and why HEPA filters are vital for air purity in homes, labs, and pharmaceutical environments. Learn how to keep your air perfectly clean.

Explore how much a HEPA air filter costs and what affects its price. Learn about HEPA filter types, applications in pharmaceutical systems, maintenance, and buying tips. Discover why Everheal’s HEPA air filters guarantee GMP-level purity and performance for industrial clients.

This article explains how long a HEPA air filte lasts, the factors affecting its lifespan, maintenance best practices, and replacement guidelines. It also highlights Everheal’s integrated filtration and factory design solutions for pharmaceutical manufacturing compliance.

Air quality plays a crucial role in industries such as pharmaceuticals, healthcare, and electronics manufacturing. In these sectors, even the smallest airborne particles can compromise the integrity of production environments or damage sensitive equipment. Among the many solutions developed to ensur

Blueair purifiers use advanced HEPASilent™ technology that matches or exceeds True HEPA Air Filter performance. Learn how their hybrid system works, its benefits, and whether it suits home, industrial, or pharmaceutical environments.

This in-depth guide explores whether washable central air filters harm HVAC systems. Learn about their pros, cons, maintenance tips, and effects on air quality to decide if washable air filters suit your home or manufacturing facility.

Explore whether washable cabin air filters exist, how they work, and their benefits for cost, environment, and performance. Learn why washable air filters are ideal for vehicles, factories, and clean industrial systems like those developed by Everheal.

Discover whether Harley S&S Stage 1 air filters are washable and why they’re ideal for long-term performance. Learn cleaning steps, maintenance tips, and FAQs about washable air filters to keep your Harley running smoothly and efficiently.

Learn whether Stihl chainsaw air filters are washable and how to clean them properly. Discover the benefits of a Washable Air Filter, maintenance tips, replacement guidelines, and FAQs to keep your Stihl chainsaw running efficiently and extending engine life.

This comprehensive guide explores whether the air filter in the Stihl 029 chainsaw is washable, providing detailed information on the design, cleaning process, benefits, and maintenance tips for a washable air filter. The article also includes a conclusion and a set of frequently asked questions to help users maximize the lifespan and performance of their chainsaw.

Blueair purifiers use HEPASilent™ filtration technology to deliver HEPA Air Filter performance with enhanced quietness, energy efficiency, and higher particle capture. Learn how Blueair ensures cleaner air for households, offices, and even pharmaceutical-grade environments.

Discover whether you need a HEPA Air Filter for your air purifier. Learn how HEPA filters work, their importance in homes and pharmaceutical industries, and how Everheal’s advanced purification systems use HEPA technology to ensure safe, clean, and compliant air quality worldwide.

Learn how HEPA Air Filters work and why they’re the gold standard in air purification. Explore their mechanisms, applications in pharmaceuticals, hospitals, and homes, along with benefits, limitations, and maintenance tips for cleaner, healthier environments.

This article explores whether you can wash a HEPA filter air purifier, explaining the risks of washing True HEPA filters, how to maintain them properly, and how Everheal’s pharmaceutical systems integrate reliable HEPA air filtration for guaranteed purity and performance.

Maintaining HEPA air filters is critical for ensuring the highest air quality standards in pharmaceutical and manufacturing environments. Although it might be tempting to wash or reuse HEPA filters to save costs, doing so can compromise their integrity and filtration capability. Proper handling, timely replacement, and preventive maintenance practices are the best ways to sustain effective filtration. Always adhere to manufacturer guidelines and industry standards to guarantee a safe and contaminant-free environment.

In the modern industrial and residential air filtration market, the demand for sustainable, cost-effective, and high-performance filtration solutions has grown tremendously. Among the various options available, the washable air filter has become one of the most talked-about innovations. But what exactly makes it the best choice? How does it compare with disposable filters? And which washable air filter models stand out for efficiency and durability?

Discover whether a washable air filter is a good choice for your home or industrial system. Learn its benefits, maintenance tips, and limitations, and explore how washable air filters support sustainable air management in pharmaceutical and manufacturing environments.

Discover how air purifiers with washable filters improve air quality while cutting costs and environmental impact. Learn their benefits, applications, maintenance tips, and how they support sustainable manufacturing in homes, industries, and pharmaceutical facilities.

K&N washable air filters are durable, eco-friendly, and designed for lifetime use. Learn how to clean, maintain, and maximize performance from your washable air filter while reducing waste and boosting efficiency across automotive and industrial systems.

This detailed guide explains whether air purifier filters are washable, exploring how washable air filters work, their pros and cons, cleaning methods, and ideal applications in homes and industries like pharmaceuticals—helping users achieve efficient and sustainable air purification.