Content Menu

● What Is a Washable Air Filter?

● Why Choose Washable Air Filters for Pharmaceutical and Industrial Use

● Understanding Key Performance Indicators

>> 1. Filtration Efficiency

>> 2. Pressure Drop

>> 3. Dust-Holding Capacity

>> 4. Frame and Media Durability

>> 5. Cleaning and Maintenance Frequency

● Materials Used in Washable Air Filters

● How To Pick The Right Washable Air Filter

>> 1. Determine Air Quality Requirements

>> 2. Assess Operating Environment

>> 3. Confirm Compatibility with HVAC System

>> 4. Evaluate Cleaning and Maintenance Logistics

>> 5. Consider Total Cost of Ownership

>> 6. Verify Certifications and Quality Control

● Cleaning and Maintenance Tips

● Common Mistakes to Avoid

● Integration of Washable Air Filters in Everheal Systems

● Environmental and Economic Benefits

● Conclusion

● FAQ: Washable Air Filter Selection and Use

>> 1. How often should a washable air filter be cleaned?

>> 2. Can washable air filters replace HEPA filters?

>> 3. What's the lifespan of a washable air filter?

>> 4. Are washable air filters energy-efficient?

>> 5. What factors indicate it's time to replace a washable filter?

In modern pharmaceutical, healthcare, and industrial environments, air purity is not just a quality standard—it is a fundamental requirement. The use of Washable Air Filters has become increasingly common due to their efficiency, cost-effectiveness, and sustainability compared to disposable filters. But with numerous models and specifications available, how do you pick the right one for your facility?

As a global provider of advanced pharmaceutical equipment and cleanroom solutions, Everheal understands that the right filtration system can directly impact product quality, operational stability, and regulatory compliance. This in-depth guide uncovers every factor to consider when selecting a Washable Air Filter, ensuring your system delivers the performance your process demands.

What Is a Washable Air Filter?

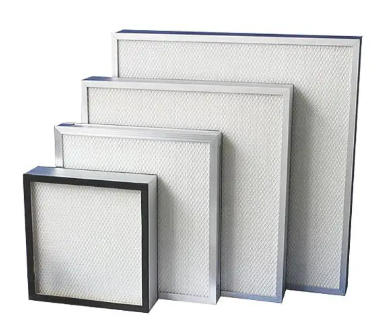

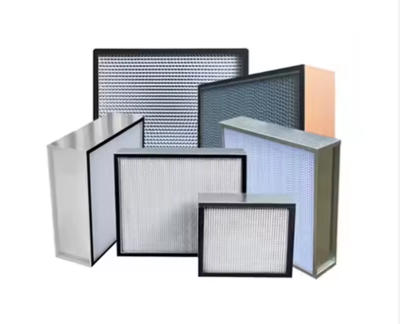

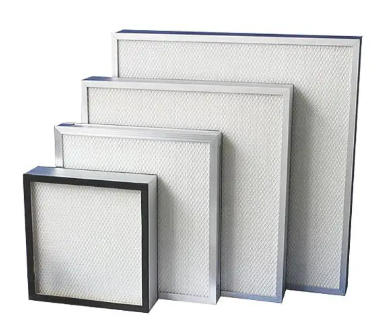

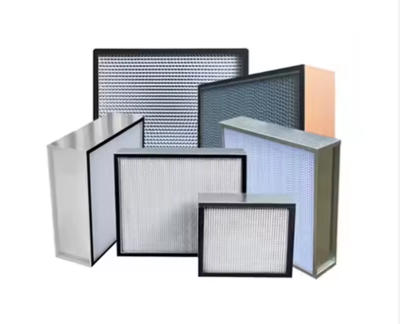

A Washable Air Filter is a reusable filtration unit designed to capture airborne dust, particles, and contaminants while allowing for easy cleaning and reinstallation. Unlike disposable filters, washable types are often made from durable materials such as aluminum mesh, stainless steel layers, or synthetic fibers designed to withstand repeated washing cycles.

These filters are used in HVAC systems, cleanroom environments, pharmaceutical production lines, laboratories, and industrial facilities where air quality plays a critical role in maintaining sterile and controlled conditions.

Key advantages of washable filters include:

- Cost savings over time: Reduced replacement frequency and maintenance costs.

- Sustainability: Less waste generation compared to disposable filters.

- Customizable performance: Adjustable filtration grades and materials for specific environments.

Why Choose Washable Air Filters for Pharmaceutical and Industrial Use

Pharmaceutical and industrial applications demand continuous air handling with minimal contamination risk. Washable filters ensure long-term reliability while supporting GMP and ISO cleanroom standards.

Here are the main reasons industries prefer Washable Air Filters:

1. Regulatory compliance – Meets air cleanliness levels required by FDA, EMA, and WHO GMP standards.

2. Improved air stability – Ensures consistent pressure drop and airflow across filtration cycles.

3. Extended service life – High-quality washable filters can last several years with proper care.

4. Eco-efficiency – Reduces carbon footprint and disposable filter waste.

5. Versatility – Suitable for pre-filtration in multi-stage systems or standalone use in low-contaminant zones.

For a company like Everheal, specializing in integrated purification systems—such as pure steam generators, multi-effect distillers, and sterilization units—using washable air filters ensures higher operational hygiene and reduced maintenance interruptions.

Understanding Key Performance Indicators

When choosing the ideal Washable Air Filter, several performance metrics determine its suitability for your application:

1. Filtration Efficiency

Measured by standards such as EN 779:2012, ISO 16890, or ASHRAE 52.2, efficiency indicates the filter's ability to remove particles of specific sizes. In cleanroom or pharmaceutical settings, filters often require efficiency ranging from MERV 8 to MERV 14 before final HEPA or ULPA filtration.

2. Pressure Drop

A crucial factor determining energy consumption in HVAC systems. A lower pressure drop means reduced fan load and energy usage. Washable filters should maintain stable pressure drop levels even after multiple cleaning cycles.

3. Dust-Holding Capacity

Refers to how much dust the filter can hold before reaching its maximum pressure limit. Filters with higher dust-holding capacity need less frequent cleaning, improving production continuity.

4. Frame and Media Durability

High-quality washable filters are constructed from aluminum, galvanized steel, or stainless steel frames with reinforced mesh layers to prevent corrosion and deformation under high-temperature or high-humidity conditions.

5. Cleaning and Maintenance Frequency

Not all washable filters are equally easy to clean. Some use foam or non-metallic media that can degrade with repeated washing. Filters intended for pharmaceutical use should withstand over 100 cleaning cycles without performance loss.

Materials Used in Washable Air Filters

The choice of material directly influences durability, airflow capacity, and maintenance cycles. Below are the common materials found in washable filter construction:

| Material Type | Characteristics | Common Applications |

| Aluminum Mesh | Lightweight, corrosion-resistant, excellent washing performance | HVAC systems, pharmaceutical plants, electronics factories |

| Stainless Steel | High strength, heat-resistant, suitable for sterilizable air systems | Cleanrooms, sterile environments |

| Synthetic Fiber or Foam | Good filtration for coarse particles, flexible structure | General air purification, industrial prefiltering |

| Galvanized Steel Frame | Economical and rigid, corrosion-protected | Factories, heavy-duty environments |

For Everheal's manufacturing clients, selecting stainless steel mesh filters is often ideal because they align with hygiene and sterilization requirements in pharmaceutical production.

How To Pick The Right Washable Air Filter

To select the most effective Washable Air Filter for your facility, you should thoroughly evaluate both environmental and operational factors.

1. Determine Air Quality Requirements

Start by defining the target air purity level. For pharmaceutical production, areas must often reach ISO 7 or ISO 8 cleanroom classification, requiring pre-filters combined with HEPA filtration. Washable filters serve as the first line of defense to capture large particles.

2. Assess Operating Environment

Operating conditions such as humidity, temperature, and contaminant type affect filter selection.

- High humidity: Choose stainless steel or synthetic mesh filters resistant to corrosion.

- Dust-heavy areas: Select multi-layer aluminum models with high dust retention.

3. Confirm Compatibility with HVAC System

Check the filter's dimensions, pressure limits, and airflow ratings to ensure compatibility with your existing ventilation or cleanroom air handling unit.

4. Evaluate Cleaning and Maintenance Logistics

An ideal washable filter should allow effortless cleaning with water or mild detergent. Evaluate access points, washing cycles, and drying times for minimal downtime.

5. Consider Total Cost of Ownership

Although washable filters have higher upfront costs, their lifespan dramatically reduces replacement expenses. Over a 5-year cycle, washable solutions can cut filtration costs by over 50% compared to disposables.

6. Verify Certifications and Quality Control

Always confirm that filters comply with international standards such as:

- ISO 16890 for particulate matter efficiency

- EN 779 for general HVAC performance

- RoHS and REACH for material safety

For regulated industries, this step is non-negotiable.

Cleaning and Maintenance Tips

To maximize the lifespan of a Washable Air Filter, follow proper cleaning and reinstallation protocols:

1. Remove the filter carefully from its housing, ensuring no dust spills into the system.

2. Rinse with warm water in the opposite direction of airflow to remove surface contaminants.

3. If heavily soiled, use mild detergent or compressed air (for metal filters only).

4. Ensure complete drying before reinstalling to prevent microbial growth.

5. Inspect frames and seals regularly for corrosion or wear.

For critical pharmaceutical systems, Everheal recommends maintaining a cleaning log to track filter performance and replacement cycles.

Common Mistakes to Avoid

- Using non-certified filters in GMP or cleanroom environments.

- Neglecting regular maintenance, leading to microbial contamination.

- Mixing different filter classes within the same airflow zone.

- Applying harsh cleaning chemicals, which degrade filter material.

Proper attention to these aspects ensures your washable filters continuously meet air quality goals without operational interruptions.

Integration of Washable Air Filters in Everheal Systems

At Everheal, our engineering teams design complete pharmaceutical production environments that integrate seamlessly with advanced filtration systems. Each Washable Air Filter used in our cleanroom ventilation systems is tested for particle retention efficiency, airflow stability, and long-term washability.

Combined with pure water preparation systems, pure steam generators, and sterilizers, these air filters form part of a closed-loop contamination control architecture that supports clients in meeting global pharmaceutical quality standards.

Environmental and Economic Benefits

Switching to Washable Air Filters has both economic and environmental advantages:

- Reduced waste output: Minimizes landfill waste associated with disposable filters.

- Lower long-term cost: A single washable unit can replace dozens of disposable filters.

- Energy savings: Maintains a stable airflow profile, decreasing HVAC energy demand.

- Carbon reduction: Supports corporate ESG and sustainability goals.

For manufacturers looking to align with green production initiatives, washable air filters represent a tangible and measurable step toward resource efficiency.

Conclusion

Choosing the right Washable Air Filter requires more than just picking a reusable model—it involves assessing efficiency, materials, air system compatibility, maintenance requirements, and long-term cost benefits. High-quality washable filters, especially when integrated into advanced systems like those designed by Everheal, can transform your air management strategy from reactive maintenance to proactive quality assurance.

By investing in durable, certified, and easy-to-clean washable filters, pharmaceutical and industrial operations can enhance both environmental performance and operational reliability.

FAQ: Washable Air Filter Selection and Use

1. How often should a washable air filter be cleaned?

Ideally, washable air filters should be cleaned every 3 to 6 months, depending on the contamination level and operational environment. In cleanrooms or pharmaceutical facilities, more frequent inspection—every 4 to 6 weeks—is recommended.

2. Can washable air filters replace HEPA filters?

No. Washable air filters serve as pre-filters to capture large particles before HEPA or ULPA filters. They extend the lifespan of high-efficiency filters but cannot replace them in sterile environments.

3. What's the lifespan of a washable air filter?

A well-maintained filter can last 5 to 10 years, depending on material quality, cleaning frequency, and working conditions.

4. Are washable air filters energy-efficient?

Yes. Because of stable airflow and reduced pressure drop over time, these filters maintain consistent HVAC performance, contributing to overall energy savings.

5. What factors indicate it's time to replace a washable filter?

If the filter's frame corrodes, the mesh tears, or efficiency drops significantly despite cleaning, replacement is necessary to maintain air system integrity.