Views: 222 Author: Rebecca Publish Time: 2025-12-12 Origin: Site

Content Menu

● Understanding the Function of a HEPA Air Filter

● Can You Wash a HEPA Filter Air Purifier?

● Why You Shouldn't Wash True HEPA Filters

>> Loss of Electrostatic Charge

>> Moisture Retention and Mold Growth

● Maintenance Tips for HEPA Air Filter Air Purifiers

>> 4. Monitor Airflow and Odor

>> 5. Store Spare Filters Properly

● What About Washable HEPA-Type Filters?

● HEPA Air Filters in Industrial and Pharmaceutical Systems

● Signs That Your HEPA Air Filter Needs Replacement

● Cost, Performance, and Environmental Considerations

● Responsible Disposal Practices for HEPA Filters

● Advancements in HEPA Filter Technology

● The Importance of Professional Service Support

● FAQ

>> 1. Can all HEPA filters be washed?

>> 2. How often should I replace a HEPA Air Filter?

>> 3. What happens if I use a washed HEPA filter again?

>> 4. Is vacuuming a HEPA filter an effective alternative?

>> 5. Are washable HEPA-type filters as good as True HEPA filters?

In today's world, ensuring clean and safe air is no longer a luxury—it's a necessity. Whether in homes, laboratories, hospitals, or pharmaceutical factories, maintaining pure air quality not only protects human health but also safeguards sensitive equipment and production environments. At the heart of this effort is the HEPA Air Filter, a critical component known for its exceptional filtration efficiency.

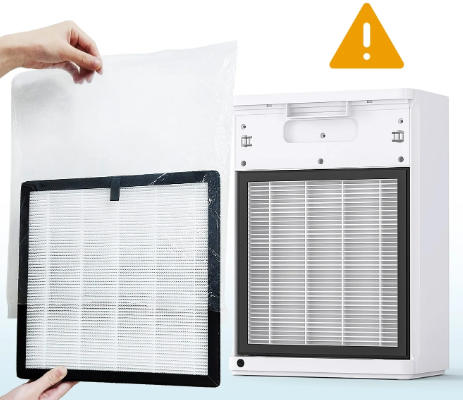

However, despite its popularity and technological importance, one question is commonly asked by users: Can you wash a HEPA filter air purifier? The idea seems appealing—washing to reuse sounds cost-effective and eco-friendly—but the truth is much more nuanced. Understanding the science behind HEPA filters can help you protect your purifier system and keep your environment truly clean.

The term HEPA, or *High-Efficiency Particulate Air*, describes a type of air filter capable of removing at least 99.97% of airborne particles measuring 0.3 microns or larger. These particles include dust, pollen, bacteria, mold spores, and even some viruses that ordinary filters cannot capture.

A HEPA Air Filter is made of an intricate mesh of fine fibers—usually fiberglass or advanced synthetic materials—arranged in a dense, random pattern. As air passes through the filter, several mechanisms trap particles:

- Interception: Larger particles following airflow streams collide with and stick to fibers.

- Impaction: Heavier particles cannot follow the curving airstreams and directly hit fibers.

- Diffusion: Ultrafine particles move erratically, eventually contacting filter fibers through Brownian motion.

This combined process ensures maximum efficiency without restricting airflow dramatically. In professional environments—such as the pharmaceutical equipment engineered by Everheal—HEPA filters ensure sterile conditions for production lines and laboratory applications.

The short answer is usually no. True HEPA Air Filters are not designed to be washed or submerged in water. Cleaning them in this way can compromise their structure and filtration efficiency.

When a manufacturer labels a filter as “True HEPA,” it means that the product has undergone stringent efficiency tests and meets international standards such as EN 1822 or DOE STD-3020. This certification ensures that the filter can consistently trap dangerous microparticles without leakage. Washing disrupts this delicate balance.

In contrast, some brands produce HEPA-type or washable HEPA-like filters, which may sound similar but do not provide the same level of filtration. They are made from different materials and designed for limited reusability. Therefore, before cleaning any air purifier filter, you should check the manufacturer's documentation to confirm whether it's washable.

For high-grade systems—such as those designed by Everheal for pharmaceutical use—filters typically fall under the “True HEPA” category. These filters support ultra-clean environments where even minor performance degradation can lead to serious contamination risks.

Washing a HEPA filter may seem harmless, but once exposed to water, the fine fiber structure begins to deform. The fibers are extremely thin, and high pressure or moisture can break them apart, creating gaps large enough for contaminants to pass through.

Many HEPA Air Filters rely partly on an electrostatic charge to attract smaller particles. When the filter becomes wet, this electrical charge dissipates, making the filter significantly less effective.

Even after air-drying, residual moisture can remain between fiber layers. This creates ideal conditions for bacteria and mold, transforming the air purifier from a cleaning device into a contamination source.

Attempting to rinse or shake loose dust may actually spread harmful particulates back into the air, which defies the purpose of purification.

For these reasons, washing True HEPA filters is not recommended. It can cause long-term damage and affect air quality even more negatively than a clogged filter would.

Instead of washing, users should apply proper maintenance and replacement techniques to maximize the filter's lifespan and performance. Here are some key recommendations:

Most HEPA Air Filter air purifiers include a pre-filter designed to capture larger dust and debris particles before they reach the HEPA layer. These pre-filters are often washable or vacuum-safe. Cleaning them every 2–4 weeks will relieve pressure on the HEPA filter and extend its effective life.

If the surface of the HEPA filter appears visibly dusty, use a low-suction vacuum cleaner with a soft brush to gently lift off contaminants from the surface. Do not press or bend the filter, as it may damage internal fibers.

Even with careful maintenance, no HEPA filter lasts forever. Depending on usage and environmental conditions, replacement intervals generally range between 6 to 12 months for domestic air purifiers. Industrial systems, especially in sterile manufacturing, often require more frequent checks.

If you notice reduced airflow or an unpleasant odor from the purifier, it may signal that the filter has reached the end of its usable life. Never attempt washing—cleaning temporarily helps, but replacement prevents deeper contamination.

Keep replacement HEPA Air Filters sealed in dry environments away from humidity, dust, or chemicals. Incorrect storage may degrade fiber performance even before use.

While traditional HEPA filters cannot be washed, some air purifier manufacturers now develop washable HEPA-type filters, often made from durable synthetic fibers or polyester blends. These filters can tolerate limited cleaning.

If your air purifier uses such a filter, follow these steps carefully:

1. Remove the filter and gently tap it to dislodge loose particles.

2. Rinse the filter under cold running water—never use detergents, cleaning agents, or brushes.

3. Let the filter dry naturally for at least 24–48 hours. Do not expose it to direct sunlight or high heat.

4. Reinstall the filter only when completely dry to avoid moisture damage to internal electronics.

However, even washable models lose efficiency after multiple cleaning cycles. They may trap fewer fine particles compared to True HEPA filters, so replacement remains necessary after a few months of heavy use.

In pharmaceutical engineering, every breath of air matters. The HEPA Air Filter forms the backbone of cleanroom HVAC systems, ensuring a controlled, particle-free environment that meets ISO Class 5–8 standards.

Everheal, as a global provider of pharmaceutical machinery and purification solutions, integrates certified HEPA filters into its product lines, including pure water generation systems, pure steam generators, distillation units, liquid filling and sealing machines, and sterilization systems. These systems rely on non-washable, high-efficiency HEPA filters to prevent microbial and particulate contamination during production.

Attempting to wash these filters would not only compromise their performance but could also violate strict GMP and FDA cleanliness regulations. That's why Everheal systems are designed with modular, easily replaceable HEPA filter assemblies, simplifying maintenance and ensuring stable air quality.

It's essential to recognize when your HEPA Air Filter Air Purifier can no longer perform effectively. Watch for these warning signs:

- Reduced airflow: The purifier's fan runs faster or louder, but air output feels weak.

- Unpleasant odor: A musty smell suggests microbial growth inside the clogged filter.

- Visible discoloration: The filter appears gray or dusty even after surface cleaning.

- Allergy symptoms return: You start sneezing or coughing more frequently, indicating deteriorated air quality.

- System warning indicator: Many advanced purifiers display filter replacement lights or error codes.

Once these symptoms appear, purchase a replacement compatible with your purifier model, following the manufacturer's certification requirements.

Replacing a HEPA filter might seem costly, but the long-term health and environmental benefits outweigh the expense. Air-borne contaminants like PM2.5, bacteria, and chemical vapors can severely impact respiratory health. Investing in a clean, high-quality HEPA Air Filter ensures both personal safety and proper function of sensitive systems.

Moreover, filter replacement supports energy efficiency. A clogged or damaged HEPA filter forces the air purifier motor to work harder, consuming more electricity and reducing overall lifespan. Regular replacement maintains airflow balance, prolonging both filter and system durability.

For environmentally conscious users, some manufacturers now offer recycling programs for used HEPA filters, or you can cooperate with industrial support teams—such as Everheal's technical maintenance division—for safe waste handling compliant with environmental regulations.

Dirty HEPA filters accumulate allergens, dust, and potentially hazardous microorganisms. Disposing of them safely is essential not only for hygiene but also for environmental protection.

Here's how to handle used HEPA Air Filters:

1. Turn off the purifier and remove the filter carefully to avoid releasing trapped dust.

2. Immediately place the used filter inside a plastic or biodegradable bag.

3. Seal the bag and dispose of it with household trash or follow local hazardous waste rules.

4. For industrial applications, Everheal advises managing used filters as potentially bio-contaminated material, ensuring compliance with health and safety regulations.

5. If the filter shows oil or chemical contamination, contact professional waste management services for proper disposal.

By following these steps, you keep both your air purifier and the surrounding environment clean and safe.

HEPA filtration technology continues to evolve to address modern air quality challenges. Manufacturers are experimenting with nanofiber coatings, activated carbon combinations, and antimicrobial treatments to extend lifespan and improve efficiency.

Some next-generation HEPA Air Filters are incorporating smart sensors that monitor real-time air resistance and alert users about performance drop-offs. This innovation not only encourages timely replacement but also optimizes energy consumption by balancing airflow and filtration rates.

For pharmaceutical companies using Everheal systems, these smart HEPA integrations can support automated cleanroom management—providing data analytics on air quality trends and preventative maintenance scheduling.

Especially in complex industrial or pharmaceutical environments, it's crucial to partner with professionals for filter inspection and replacement. Everheal provides global clients with end-to-end technical support, including:

- System design optimization for airflow and filtration zones.

- Regular auditing and performance testing using particle counters.

- Rapid response replacement services for HEPA filtration modules.

- Staff training on GMP-compliant filter handling and documentation.

This level of professional service ensures that cleanroom operations remain fully compliant and risk-free throughout the equipment's life cycle.

In summary, you should not wash a True HEPA Air Filter. The fine fiber networks and electrostatic charge essential for high filtration efficiency are irreversibly damaged by water. While some washable HEPA-type filters exist, their performance and lifespan are considerably shorter.

To maintain excellent air purification results—whether for household comfort or for demanding pharmaceutical operations—regular maintenance, careful surface cleaning, and timely replacement are the only reliable practices. In industrial contexts, especially those requiring sterile environments, clean air isn't optional—it's a regulatory and operational necessity.

Everheal continues to support global partners by providing technology-driven purification systems, from pure steam generators to sterilization units, each built around non-washable, high-efficiency HEPA Air Filters that ensure clean, safe, and sustainable air for modern production.

No. True HEPA filters should never be washed or immersed in water. Doing so damages their microstructure and destroys filtration performance. Only HEPA-like washable filters explicitly labeled “washable” can be gently rinsed.

Most filters require replacement every 6–12 months depending on air quality and usage. Industrial and cleanroom environments may need more frequent changes under strict monitoring schedules.

A washed HEPA filter loses its structural integrity and electrostatic charge. This means it can no longer capture the smallest particles, allowing dust, bacteria, or allergens to circulate freely.

Vacuuming is safe only for surface dust removal. It temporarily improves airflow but cannot restore deep filtration efficiency. Always follow this by replacing the filter when performance drops.

Not quite. Washable HEPA-type filters may capture medium-sized particles effectively but fail to achieve the 99.97% efficiency of true HEPA filters tested at 0.3 microns. They're more suitable for casual household use rather than industrial or pharmaceutical applications.

Blueair purifiers use HEPASilent™ filtration technology to deliver HEPA Air Filter performance with enhanced quietness, energy efficiency, and higher particle capture. Learn how Blueair ensures cleaner air for households, offices, and even pharmaceutical-grade environments.

Discover whether you need a HEPA Air Filter for your air purifier. Learn how HEPA filters work, their importance in homes and pharmaceutical industries, and how Everheal’s advanced purification systems use HEPA technology to ensure safe, clean, and compliant air quality worldwide.

Learn how HEPA Air Filters work and why they’re the gold standard in air purification. Explore their mechanisms, applications in pharmaceuticals, hospitals, and homes, along with benefits, limitations, and maintenance tips for cleaner, healthier environments.

This article explores whether you can wash a HEPA filter air purifier, explaining the risks of washing True HEPA filters, how to maintain them properly, and how Everheal’s pharmaceutical systems integrate reliable HEPA air filtration for guaranteed purity and performance.

Maintaining HEPA air filters is critical for ensuring the highest air quality standards in pharmaceutical and manufacturing environments. Although it might be tempting to wash or reuse HEPA filters to save costs, doing so can compromise their integrity and filtration capability. Proper handling, timely replacement, and preventive maintenance practices are the best ways to sustain effective filtration. Always adhere to manufacturer guidelines and industry standards to guarantee a safe and contaminant-free environment.

In the modern industrial and residential air filtration market, the demand for sustainable, cost-effective, and high-performance filtration solutions has grown tremendously. Among the various options available, the washable air filter has become one of the most talked-about innovations. But what exactly makes it the best choice? How does it compare with disposable filters? And which washable air filter models stand out for efficiency and durability?

Discover whether a washable air filter is a good choice for your home or industrial system. Learn its benefits, maintenance tips, and limitations, and explore how washable air filters support sustainable air management in pharmaceutical and manufacturing environments.

Discover how air purifiers with washable filters improve air quality while cutting costs and environmental impact. Learn their benefits, applications, maintenance tips, and how they support sustainable manufacturing in homes, industries, and pharmaceutical facilities.

K&N washable air filters are durable, eco-friendly, and designed for lifetime use. Learn how to clean, maintain, and maximize performance from your washable air filter while reducing waste and boosting efficiency across automotive and industrial systems.

This detailed guide explains whether air purifier filters are washable, exploring how washable air filters work, their pros and cons, cleaning methods, and ideal applications in homes and industries like pharmaceuticals—helping users achieve efficient and sustainable air purification.

Everheal explains what pharmaceutical preparations are, their processes, and essential equipment like purified water systems, pure steam generators, and sterilization units. Learn how Everheal supports global manufacturers with GMP-compliant turnkey pharmaceutical solutions.

Everheal explores the engineering and technology of **pharmaceutical preparation manufacturing**, revealing how purified water, sterilization, and automation drive global drug production. Discover Everheal’s role in designing compliant, efficient, and sustainable pharmaceutical manufacturing solutions.

This article explores which pharmaceutical preparations need isotonicity adjustment, explaining its physiological importance, calculation methods, and the role of advanced equipment — such as Everheal’s integrated systems — in achieving safe, effective, and GMP-compliant drug formulations worldwide.

This article explains isotonicity in pharmaceutical preparations, its role in injections, eye drops, nasal sprays, and other dosage forms, and how advanced equipment systems like purified water and sterilization units ensure consistent isotonic conditions in pharma manufacturing.

Explore the different Pharmaceutical Preparations containing ammonium bromide, including their uses, manufacturing methods, safety measures, and modern significance. Learn how cutting-edge companies like Everheal ensure high purity and quality in pharmaceutical production.

This article explains why distilled water is strongly recommended for CPAP humidifiers, how it protects both users and equipment, and what happens when other water types are used. It also shows how Everheal’s pharmaceutical‑grade Distillation Water Machine solutions supply reliable CPAP‑grade water for homes, clinics, and hospitals.

This article explains when and how distilled water can be used with fog machines, from standard stage foggers to ultrasonic and low‑lying systems. It shows why distilled water is ideal for cleaning and certain water‑fog devices, and how a high‑purity Distillation Water Machine supports reliable, low‑maintenance fog effects in professional and pharmaceutical environments.

This in‑depth article explains why distilled water is strongly recommended for CPAP humidifiers, what happens if you use tap, bottled, or boiled water, and how to manage water safely at home, in clinics, and in pharma plants. It highlights how Distillation Water Machine systems provide reliable CPAP‑grade water.

This in‑depth guide explains why distilled water is strongly recommended for oxygen machine humidifiers, how it protects both patients and equipment, and how a Distillation Water Machine supports safe oxygen therapy in hospitals, clinics, and pharmaceutical plants, with Everheal turnkey solutions.

This article explains why distilled water is strongly recommended for CPAP machines, how it protects users and devices, and what happens if other water types are used. It highlights the role of pharmaceutical‑grade Distillation Water Machine solutions—like Everheal’s—in delivering reliable CPAP‑grade water for homes, clinics, and factories.