Content Menu

● Understanding Washable Engine Air Filters

>> Advantages of a Washable Air Filter

● When Should You Clean Your Washable Air Filter?

● Tools and Materials You'll Need

● Step-by-Step Guide: How to Clean a Washable Engine Air Filter

>> Step 1: Remove the Filter from the Vehicle

>> Step 2: Pre-Clean the Filter

>> Step 3: Apply Cleaning Solution

>> Step 4: Rinse with Low-Pressure Water

>> Step 5: Dry the Filter Completely

>> Step 6: Re-Oil the Filter (For Oiled Types)

>> Step 7: Reinstall the Filter

● Common Mistakes to Avoid

● Maintenance Tips for Longer Filter Life

● Benefits of Regular Cleaning

● Conclusion

● FAQ

>> 1. How often should I clean my washable air filter?

>> 2. Can I use soap or detergent instead of filter cleaner?

>> 3. Is it safe to use compressed air to dry the filter?

>> 4. What happens if I over-oil my filter?

>> 5. Can washable air filters fit all vehicles?

In modern automotive maintenance, one simple yet powerful way to improve engine performance, reduce fuel consumption, and extend your vehicle's lifespan is by regularly cleaning the washable engine air filter. Unlike traditional disposable filters, washable air filters are designed for multiple cleaning cycles, offering long-term cost savings and environmental benefits. Yet many car owners don't fully understand the correct steps or precautions needed during the cleaning process.

This detailed guide explains how to properly clean a washable engine air filter, what cleaning agents to use, how to dry and reinstall it, and how to maintain filter efficiency over time. Whether you're a mechanic, car enthusiast, or first-time DIYer, you'll find this step-by-step process both practical and easy to follow.

Understanding Washable Engine Air Filters

A washable air filter functions as the engine's first line of defense against dust, debris, and other airborne contaminants. Traditional paper filters trap particles through dense fibers but require replacement once clogged. Washable filters, however, use multilayer cotton or synthetic gauze, often with an oil coating to enhance particle attraction. These filters can be washed and reused dozens of times without losing their filtration capacity.

Advantages of a Washable Air Filter

- Cost-effective: A high-quality washable filter can last up to 10 years, eliminating the need for frequent replacements.

- Performance boost: Clean filters maintain optimal airflow, which supports better engine combustion and fuel efficiency.

- Eco-friendly: Reusable filters significantly reduce waste compared to disposable paper filters.

- Consistency: Once properly maintained, washable filters deliver consistent airflow across long-term usage.

When Should You Clean Your Washable Air Filter?

There's no universal rule for cleaning frequency, but several conditions can shorten cleaning intervals:

- Driving conditions: Dusty or unpaved roads cause faster buildup of contaminants.

- Climate: Areas with high humidity or pollen count can clog filters quicker.

- Mileage: Typically, washable filters should be cleaned every 10,000–15,000 miles (16,000–24,000 km) or whenever airflow visibly decreases.

You can also inspect the filter manually—if it appears dark, oily, or heavily coated with dirt, it's time for a wash.

Tools and Materials You'll Need

Before cleaning your washable engine air filter, prepare the following items:

- Manufacturer-approved air filter cleaning solution

- Water source (preferably low-pressure hose or tap)

- Soft-bristle brush (optional, for stubborn dirt)

- Drying towel

- Air filter oil (for oiled cotton filters)

- Protective gloves

Avoid using harsh detergents, gasoline, or compressed air—these can damage the filter media or compromise sealing surfaces.

Step-by-Step Guide: How to Clean a Washable Engine Air Filter

Step 1: Remove the Filter from the Vehicle

Turn off the engine completely and allow it to cool. Open the airbox or housing and carefully remove the washable air filter. Note its orientation and sealing position, as you'll need to reinstall it in the exact same alignment later.

Inspect for any damage—if the rubber edges are cracked or the mesh is torn, cleaning won't restore full performance and replacement might be necessary.

Step 2: Pre-Clean the Filter

Gently tap the filter against a soft surface to dislodge larger debris like insects or sand. Use a light brush stroke from the clean side outward (never scrub aggressively). This pre-cleaning step ensures the actual washing phase is more effective.

Step 3: Apply Cleaning Solution

Spray the recommended filter cleaner generously onto both sides of the filter. Make sure the cleaner penetrates the pleats. Let the solution soak for about 10 minutes to dissolve trapped oils and fine particles.

If your washable air filter is an oiled cotton type (common in performance vehicles), never use standard soap—it can strip protective oils and reduce filtration quality.

Step 4: Rinse with Low-Pressure Water

Rinse the filter from the clean side out, ensuring contaminants flow outward rather than deeper into the fibers. Maintain low water pressure to avoid damaging pleats or mesh layers. Continue rinsing until the water runs clear.

Do not use hot water, as high temperatures may weaken adhesive bonds in some filters.

Step 5: Dry the Filter Completely

Gently shake off excess water and place the filter in a clean, dry area away from direct sunlight or heat sources. Naturally air-drying may take several hours. Never use a hair dryer, heater, or compressed air, which can deform the filter material.

Ensure the filter is completely dry before proceeding to the next step—moisture left inside can affect airflow and attract mold or dust.

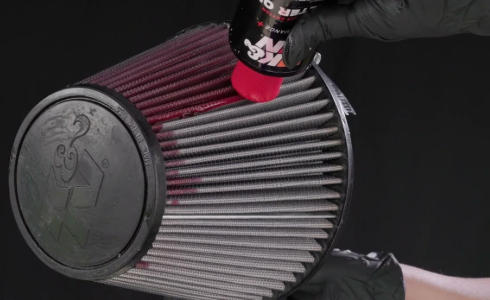

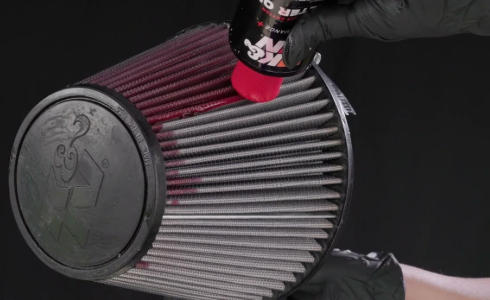

Step 6: Re-Oil the Filter (For Oiled Types)

If the washable air filter uses oil, apply the manufacturer-approved air filter oil evenly along the pleats. Avoid over-oiling, as excess oil can cause engine sensors—especially mass airflow (MAF) sensors—to malfunction.

Allow the oil to settle for about 20 minutes, then lightly examine for uniform coating. Wipe off extra oil if needed.

Step 7: Reinstall the Filter

Reinsert the dry, treated filter into its housing, making sure the sealing edges fit tightly. Secure the clamps or cover bolts and ensure no gaps allow unfiltered air to enter.

Run the engine briefly to confirm stable airflow and normal idling sound, indicating a correctly seated and cleaned filter.

Common Mistakes to Avoid

- Using harsh cleaners: Household degreasers or solvents can damage filter fibers.

- Over-oiling: Leads to sticky buildup inside the intake system.

- Insufficient drying time: Trapped moisture can restrict airflow and cause odor.

- Wrong water pressure: Strong jets may tear or fold pleats.

- Ignoring manufacturer's guidelines: Always follow brand-specific maintenance instructions.

Maintenance Tips for Longer Filter Life

1. Inspect your washable air filter every 5,000 miles, even if not visibly dirty.

2. Store a backup filter to switch out during drying periods.

3. Keep a cleaning schedule log to monitor condition and mileage.

4. Avoid off-brand oils or cleaners that may cause chemical degradation.

5. Clean the filter more often in humid or dusty climates.

Extending the lifespan of your washable air filter minimizes waste and saves costs—especially for commercial vehicle fleets or heavy-duty equipment.

Benefits of Regular Cleaning

Proper maintenance of a washable engine air filter provides several measurable benefits:

- Improved Fuel Economy: Clean airflow enables more efficient combustion.

- Enhanced Engine Power: Reduction of intake restriction leads to smoother throttle response.

- Longer Engine Lifespan: Cleaner air prevents abrasive particulates from entering cylinders.

- Reduced Emissions: Better oxygen balance reduces incomplete fuel burning.

- Sustainable Operation: Washable filters reduce disposal waste over years of use.

For industrial or pharmaceutical equipment—such as HVAC systems, gas compressors, or sterilization units—proper filtration upkeep ensures stable operation and compliance with cleanroom standards. Companies like Everheal integrate air purification systems and optimized process layouts to maintain controlled environments critical for drug manufacturing and liquid filling lines.

Conclusion

Cleaning a washable engine air filter is not only simple but also essential for maintaining long-term engine health and operational efficiency. With the right tools, proper cleaning solution, and careful drying, this process can be performed safely at home or in a maintenance facility. Regular care ensures that your filter provides optimal airflow, improves combustion, and minimizes emissions.

Investing a small amount of time in proper filter maintenance pays off in performance, savings, and sustainability. Always remember—the cleaner the air your engine breathes, the stronger and more efficient it will run.

FAQ

1. How often should I clean my washable air filter?

Ideally, clean your washable air filter every 10,000 to 15,000 miles, or sooner if driving in dusty environments. Always refer to the manufacturer's schedule for precise intervals.

2. Can I use soap or detergent instead of filter cleaner?

No. Most soaps remove vital oils and can damage the filter media. Always use cleaners specifically formulated for washable air filters.

3. Is it safe to use compressed air to dry the filter?

No. High-pressure air can puncture or deform the filter's pleats. Always air-dry naturally at room temperature.

4. What happens if I over-oil my filter?

Excess oil can contaminate airflow sensors, causing poor performance or engine warning lights. Apply oil evenly and sparingly according to recommendations.

5. Can washable air filters fit all vehicles?

Not all washable filters are universal. Check your vehicle's make and model compatibility before purchase or installation to ensure proper fit and performance.