Views: 222 Author: Rebecca Publish Time: 2025-12-12 Origin: Site

Content Menu

>> Understanding HEPA Technology

● Can You Wash a HEPA Air Filter?

>> Why Washing Is Not Recommended

>> Exceptions and Specialized HEPA Filters

● Alternatives to Washing HEPA Filters

>> Filter Cleaning and Maintenance Practices

>> Using Filter Media Sprays or Coatings

● How To Properly Maintain HEPA Air Filters?

>> Proper Installation and Sealing

>> 1. Can HEPA air filters be reused?

>> 2. How often should I replace a HEPA air filter?

>> 3. Are there washable HEPA filters available?

>> 4. What are the signs that a HEPA filter needs replacement?

>> 5. How can I extend the lifespan of my HEPA air filter?

HEPA air filters are essential components in many environments, especially in industries requiring strict air quality standards such as healthcare, manufacturing, and pharmaceutical production. Their high efficiency in removing microscopic particles makes them indispensable for ensuring clean, contaminant-free air. However, one common question that arises among users and facility managers is: Can you wash a HEPA air filter?

Proper maintenance of HEPA air filters extends their lifespan and guarantees optimal performance. This article explores whether washing a HEPA air filter is feasible, the best practices for maintaining these filters, and alternative options to prolong their useful life.

HEPA stands for High-Efficiency Particulate Air. These filters are designed to trap at least 99.97% of particles with a size of 0.3 microns, including dust, allergens, bacteria, viruses, and other airborne contaminants. This high level of filtration makes HEPA filters ideal for use in sterile environments, cleanrooms, and pharmaceutical manufacturing facilities.

A typical HEPA air filter comprises tightly woven fibers, often made of fiberglass or synthetic materials, arranged in a pleated configuration. The dense network of fibers captures airborne particles through mechanisms such as interception, impaction, and diffusion. The filter media is sealed within a frame, creating a barrier that filters air as it passes through.

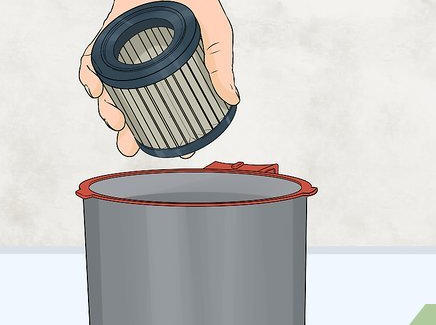

In most cases, washed or reused HEPA filters are not recommended. Manufacturers generally advise against washing HEPA filters because the cleaning process can damage the delicate fiber structure, compromise the filter's integrity, or reduce its efficiency.

- Fiber Damage: The filtration media used in HEPA filters is designed for static and mechanical filtration, not for wet cleaning. Washing can dislodge or damage the fibers, resulting in decreased effectiveness.

- Loss of Electrostatic Properties: Many HEPA filters rely on electrostatic charge to enhance particle capture. Water or cleaning agents can remove or diminish this charge, significantly reducing filtration efficiency.

- Difficulty Achieving Adequate Drying: Properly drying a HEPA filter after washing is challenging. Residual moisture can promote microbial growth or mold, further compromising the filter.

- Manufacturer Recommendations: Most manufacturers explicitly state that HEPA filters are *not washable* and should be replaced when contaminated or after their service life.

Some medical or industrial HEPA filters are designed for chemical or moist environments and may be washable under controlled conditions. Always consult the manufacturer's specifications before attempting any cleaning.

The most effective way to maintain high air quality and filter performance is to replace HEPA filters according to the manufacturer's recommended schedule. Regular replacement ensures consistent filtration efficiency and minimizes contamination risks.

- Pre-Filters: Use pre-filters to trap larger particles, reducing the load on the HEPA filter and prolonging its lifespan.

- Proper Handling: Handle HEPA filters with care to prevent physical damage during installation or replacement.

- Sealed Environments: Maintain proper sealing of filter units to prevent bypass leakage and contamination.

Some companies offer filter surface coatings that can extend the life of HEPA filters by repelling dust or microbial growth, but these should be used in conjunction with regular replacement, not as a substitute for proper maintenance.

Regular visual inspection for visible dust buildup, tears, or damage is vital. Use airflow measurements to ensure the filter's performance remains within specified parameters.

Follow the manufacturer's guidance for replacement intervals—often every 6 to 12 months, depending on operating conditions and contamination levels.

Ensure that HEPA filters are installed correctly with proper gasketing to prevent leaks. Good sealing is critical for optimal filtration performance.

Maintain controlled environments with minimal dust, humidity, and microbial contamination to prolong the service life of HEPA filters.

While washing a HEPA air filter might seem like an eco-friendly and cost-effective solution, it is generally not recommended. The delicate fiber structure, electrostatic properties, and potential for microbial growth make washing an unsuitable method for cleaning HEPA air filters. Instead, routine replacement combined with preventative maintenance—such as pre-filtration and proper installation—helps maintain optimal air quality. Always follow manufacturer guidelines and industry standards to ensure clean, safe, and efficient filtration in your pharmaceutical or manufacturing environment.

Most HEPA filters are intended for single use and should be replaced according to manufacturer recommendations. Reusing or washing filters can severely reduce their effectiveness.

Typically, HEPA filters should be replaced every 6 to 12 months, depending on usage, environment, and manufacturer instructions. In highly contaminated environments, more frequent replacement may be necessary.

Yes, some specialized HEPA filters are designed to be washable for industrial or specific medical applications. Always verify with the manufacturer whether a particular filter model is washable.

Signs include decreased airflow, increased particle counts in the environment, visible dust accumulation, or if the filter has been in use beyond its recommended lifespan.

Use pre-filters to trap larger particles, avoid direct airflow obstructions, handle filters carefully, and keep the surrounding environment clean and dust-free.

Blueair purifiers use HEPASilent™ filtration technology to deliver HEPA Air Filter performance with enhanced quietness, energy efficiency, and higher particle capture. Learn how Blueair ensures cleaner air for households, offices, and even pharmaceutical-grade environments.

Discover whether you need a HEPA Air Filter for your air purifier. Learn how HEPA filters work, their importance in homes and pharmaceutical industries, and how Everheal’s advanced purification systems use HEPA technology to ensure safe, clean, and compliant air quality worldwide.

Learn how HEPA Air Filters work and why they’re the gold standard in air purification. Explore their mechanisms, applications in pharmaceuticals, hospitals, and homes, along with benefits, limitations, and maintenance tips for cleaner, healthier environments.

This article explores whether you can wash a HEPA filter air purifier, explaining the risks of washing True HEPA filters, how to maintain them properly, and how Everheal’s pharmaceutical systems integrate reliable HEPA air filtration for guaranteed purity and performance.

Maintaining HEPA air filters is critical for ensuring the highest air quality standards in pharmaceutical and manufacturing environments. Although it might be tempting to wash or reuse HEPA filters to save costs, doing so can compromise their integrity and filtration capability. Proper handling, timely replacement, and preventive maintenance practices are the best ways to sustain effective filtration. Always adhere to manufacturer guidelines and industry standards to guarantee a safe and contaminant-free environment.

In the modern industrial and residential air filtration market, the demand for sustainable, cost-effective, and high-performance filtration solutions has grown tremendously. Among the various options available, the washable air filter has become one of the most talked-about innovations. But what exactly makes it the best choice? How does it compare with disposable filters? And which washable air filter models stand out for efficiency and durability?

Discover whether a washable air filter is a good choice for your home or industrial system. Learn its benefits, maintenance tips, and limitations, and explore how washable air filters support sustainable air management in pharmaceutical and manufacturing environments.

Discover how air purifiers with washable filters improve air quality while cutting costs and environmental impact. Learn their benefits, applications, maintenance tips, and how they support sustainable manufacturing in homes, industries, and pharmaceutical facilities.

K&N washable air filters are durable, eco-friendly, and designed for lifetime use. Learn how to clean, maintain, and maximize performance from your washable air filter while reducing waste and boosting efficiency across automotive and industrial systems.

This detailed guide explains whether air purifier filters are washable, exploring how washable air filters work, their pros and cons, cleaning methods, and ideal applications in homes and industries like pharmaceuticals—helping users achieve efficient and sustainable air purification.

Everheal explains what pharmaceutical preparations are, their processes, and essential equipment like purified water systems, pure steam generators, and sterilization units. Learn how Everheal supports global manufacturers with GMP-compliant turnkey pharmaceutical solutions.

Everheal explores the engineering and technology of **pharmaceutical preparation manufacturing**, revealing how purified water, sterilization, and automation drive global drug production. Discover Everheal’s role in designing compliant, efficient, and sustainable pharmaceutical manufacturing solutions.

This article explores which pharmaceutical preparations need isotonicity adjustment, explaining its physiological importance, calculation methods, and the role of advanced equipment — such as Everheal’s integrated systems — in achieving safe, effective, and GMP-compliant drug formulations worldwide.

This article explains isotonicity in pharmaceutical preparations, its role in injections, eye drops, nasal sprays, and other dosage forms, and how advanced equipment systems like purified water and sterilization units ensure consistent isotonic conditions in pharma manufacturing.

Explore the different Pharmaceutical Preparations containing ammonium bromide, including their uses, manufacturing methods, safety measures, and modern significance. Learn how cutting-edge companies like Everheal ensure high purity and quality in pharmaceutical production.

This article explains why distilled water is strongly recommended for CPAP humidifiers, how it protects both users and equipment, and what happens when other water types are used. It also shows how Everheal’s pharmaceutical‑grade Distillation Water Machine solutions supply reliable CPAP‑grade water for homes, clinics, and hospitals.

This article explains when and how distilled water can be used with fog machines, from standard stage foggers to ultrasonic and low‑lying systems. It shows why distilled water is ideal for cleaning and certain water‑fog devices, and how a high‑purity Distillation Water Machine supports reliable, low‑maintenance fog effects in professional and pharmaceutical environments.

This in‑depth article explains why distilled water is strongly recommended for CPAP humidifiers, what happens if you use tap, bottled, or boiled water, and how to manage water safely at home, in clinics, and in pharma plants. It highlights how Distillation Water Machine systems provide reliable CPAP‑grade water.

This in‑depth guide explains why distilled water is strongly recommended for oxygen machine humidifiers, how it protects both patients and equipment, and how a Distillation Water Machine supports safe oxygen therapy in hospitals, clinics, and pharmaceutical plants, with Everheal turnkey solutions.

This article explains why distilled water is strongly recommended for CPAP machines, how it protects users and devices, and what happens if other water types are used. It highlights the role of pharmaceutical‑grade Distillation Water Machine solutions—like Everheal’s—in delivering reliable CPAP‑grade water for homes, clinics, and factories.